Metallographic specimen grinding and polishing machine

A metallographic sample and polishing machine technology, which is applied to grinding/polishing equipment, grinders, abrasive belt grinders, etc., can solve the problems of difficulty in ensuring the quality of metallographic samples and low efficiency, and achieve high sample production efficiency. , Easy to operate, ensure the effect of production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

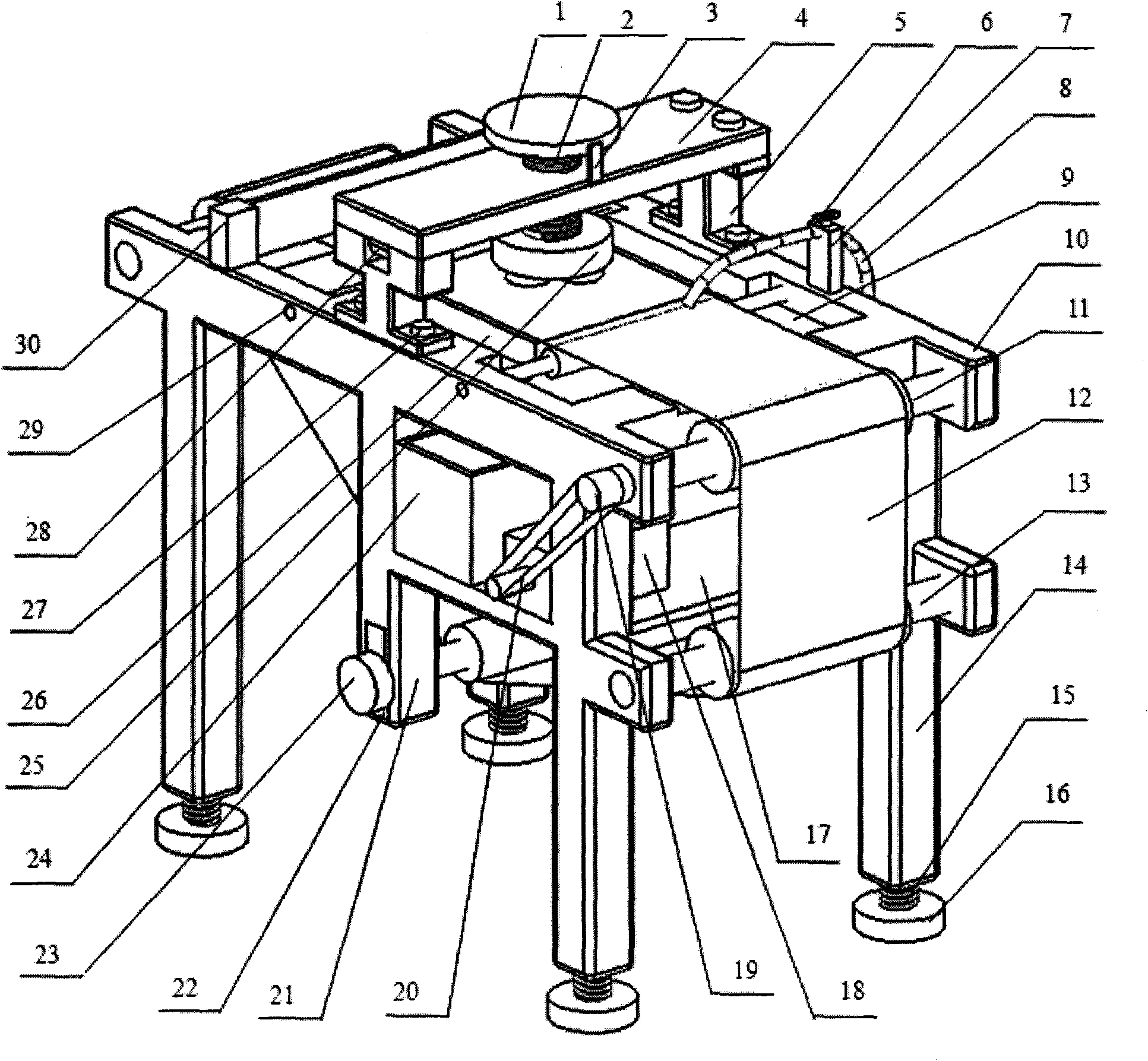

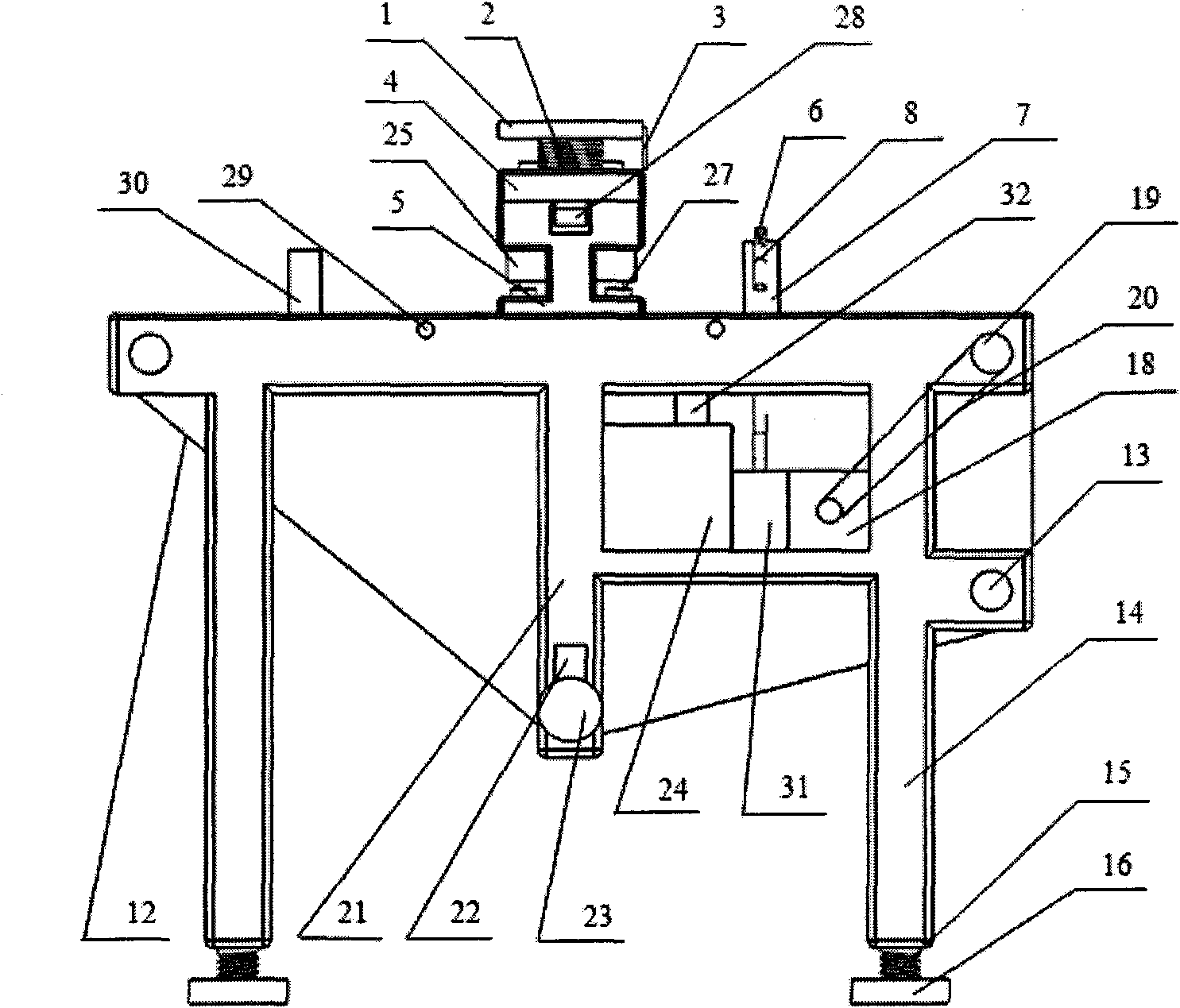

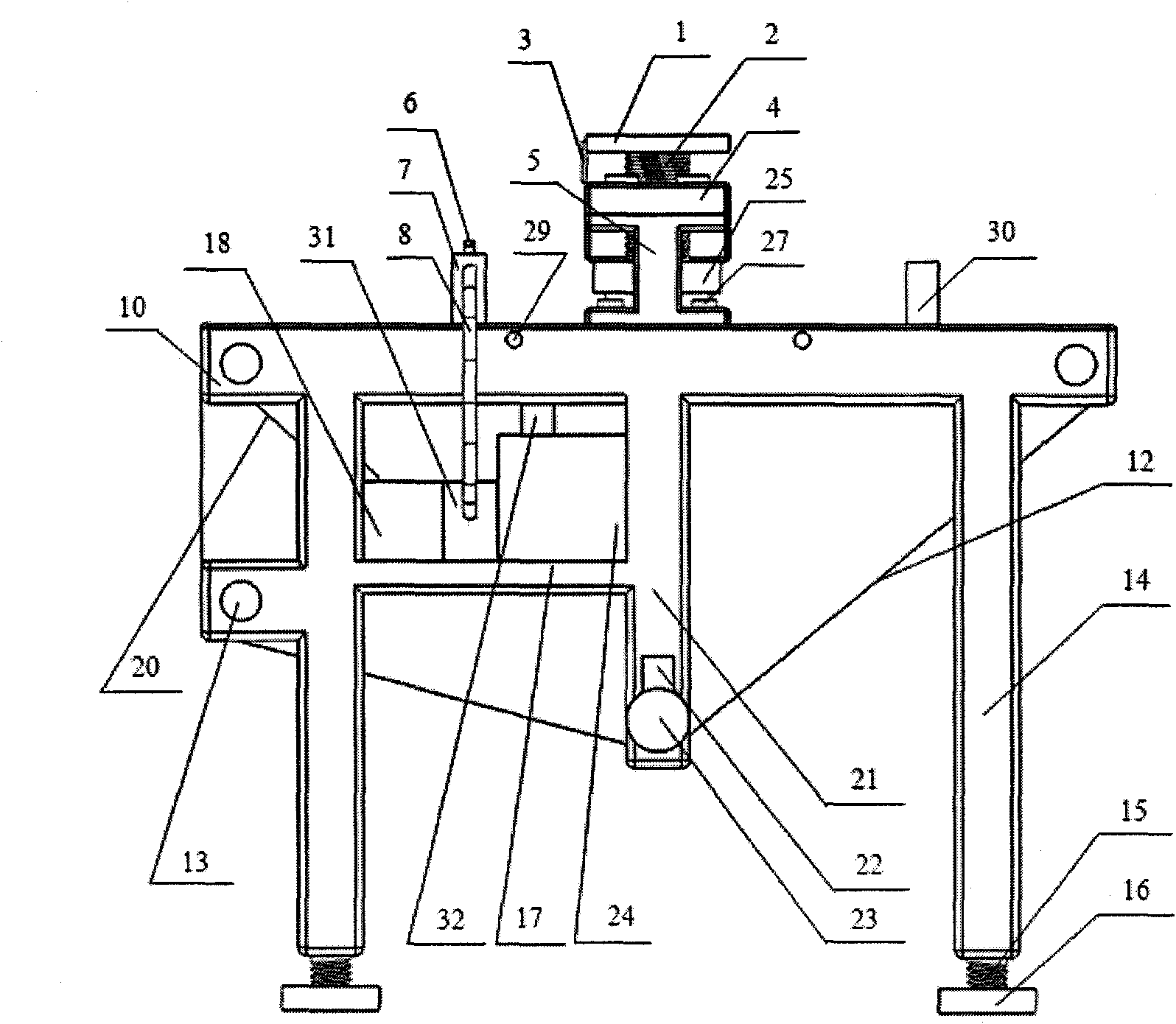

[0022] Example 1, such as Figures 1 to 7 As shown, the metallographic sample grinding and polishing machine includes a body 14 and a grinding and polishing device. It is characterized in that an upper support plate 10 and a lower support plate 17 are provided on the shown body 14, and an There is a drainage groove 9, the middle part of the upper support plate 10 is provided with a grinding and polishing bottom plate 26, the drainage groove 9 surrounds the grinding and polishing bottom plate, and the two ends of the upper support plate 10 are respectively equipped with an abrasive belt driving shaft 11 and an abrasive belt transmission shaft 13, and a pressing plate 4 Correspondingly installed on the top of the grinding and polishing base plate 26 by the upper bracket 5, the upper bracket 5 is fixedly connected with the upper support plate 10 by the fixing screw 27, one end of the pressing plate 4 is connected with the upper bracket 5 through the rotating shaft 28, and the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com