Bearing and bearing dust cover

A technology of dust cover and bearing, applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of reduced dustproof effect, bearing dust cover falling off, etc., to reduce the possibility, reduce the action area, reduce the The effect of the probability of falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] It can be seen from the background art that the installation reliability of the bearing dust cover is low, and the bearing dust cover is easy to fall off.

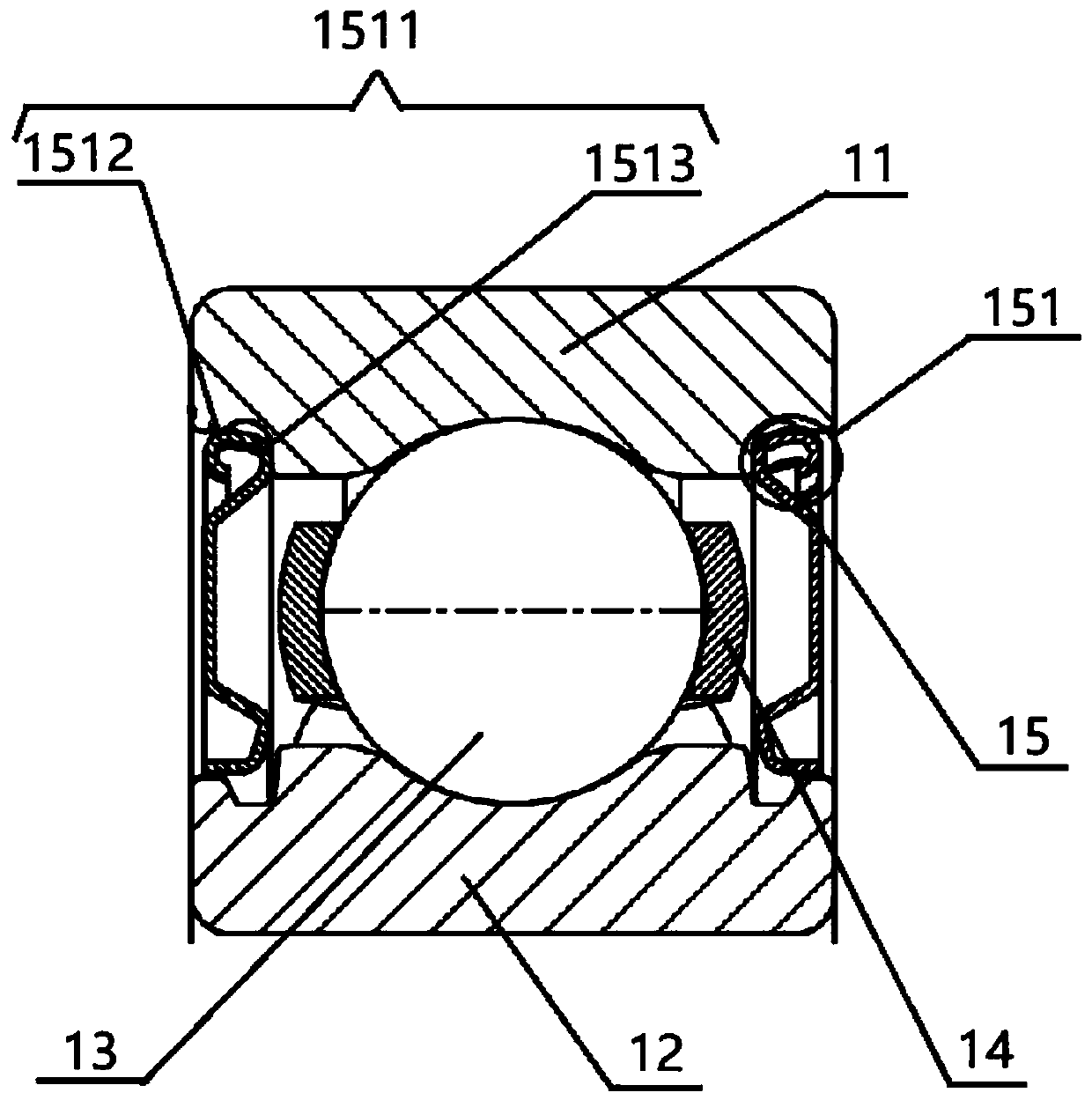

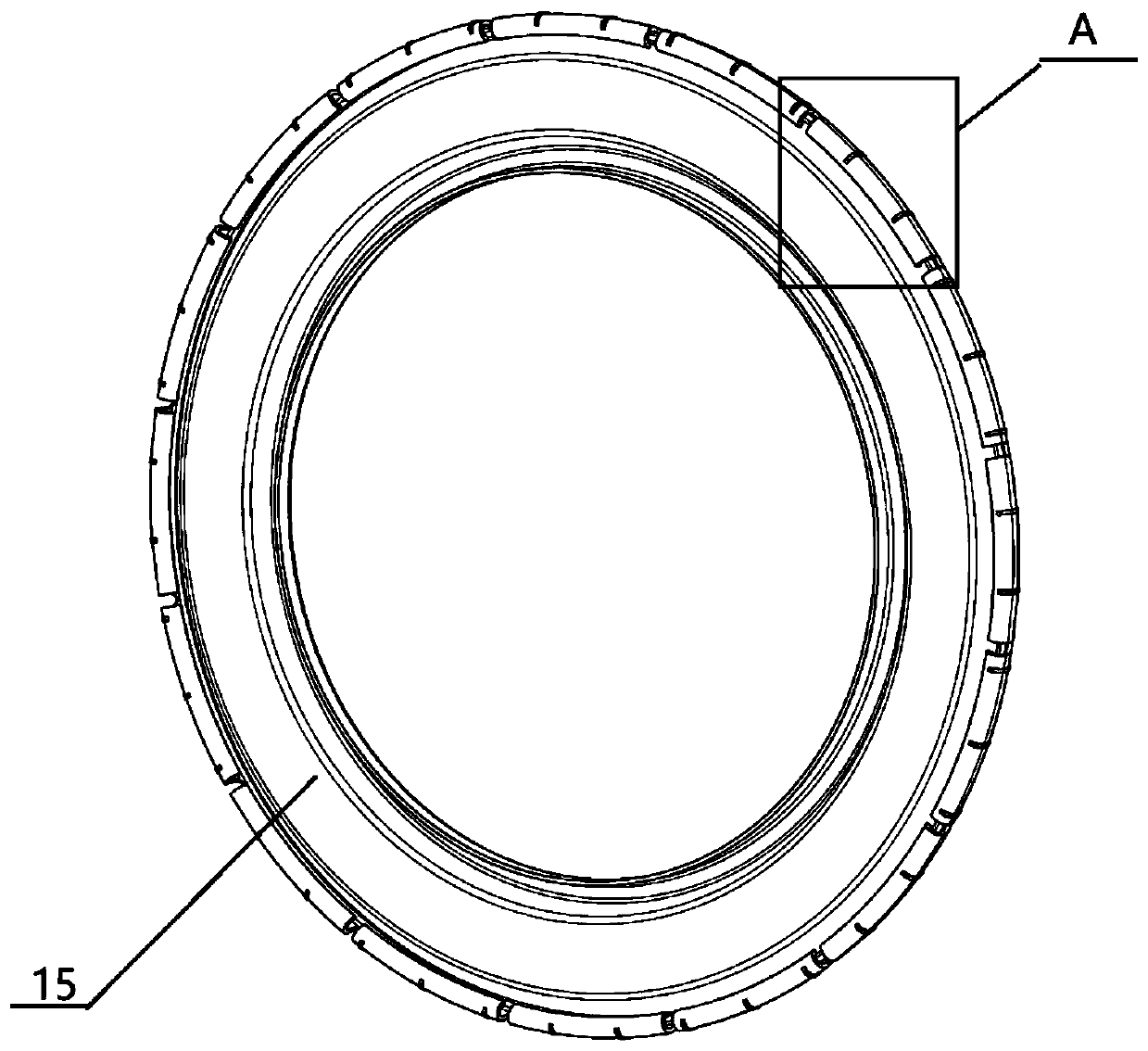

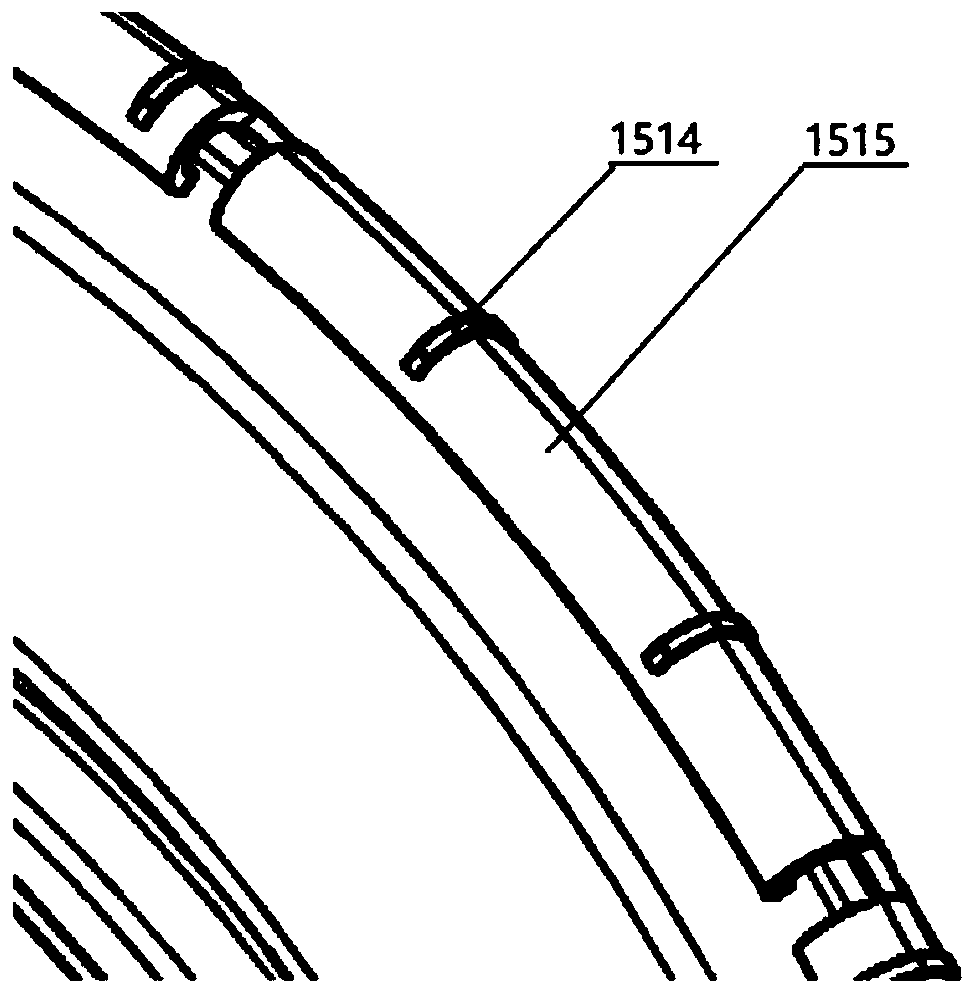

[0031] It is known that the bearing includes a bearing outer ring, a bearing inner ring, rolling elements, a cage and a bearing dust cover, and the bearing outer ring is provided with a bearing dust cover installation groove, wherein the bearing inner ring is located inside the bearing outer ring, the two The rolling elements limited by the cage are arranged between them, and the bearing dust cover is arranged at both ends of the bearing, and snapped into the bearing dust cover installation groove of the bearing outer ring.

[0032] However, when the bearing dust cover is installed in the bearing dust cover installation groove of the bearing outer ring, the bearing dust cover may not be deformed according to the expected deformation amount, thereby causing the bearing dust cover to fall off.

[0033] In order to sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com