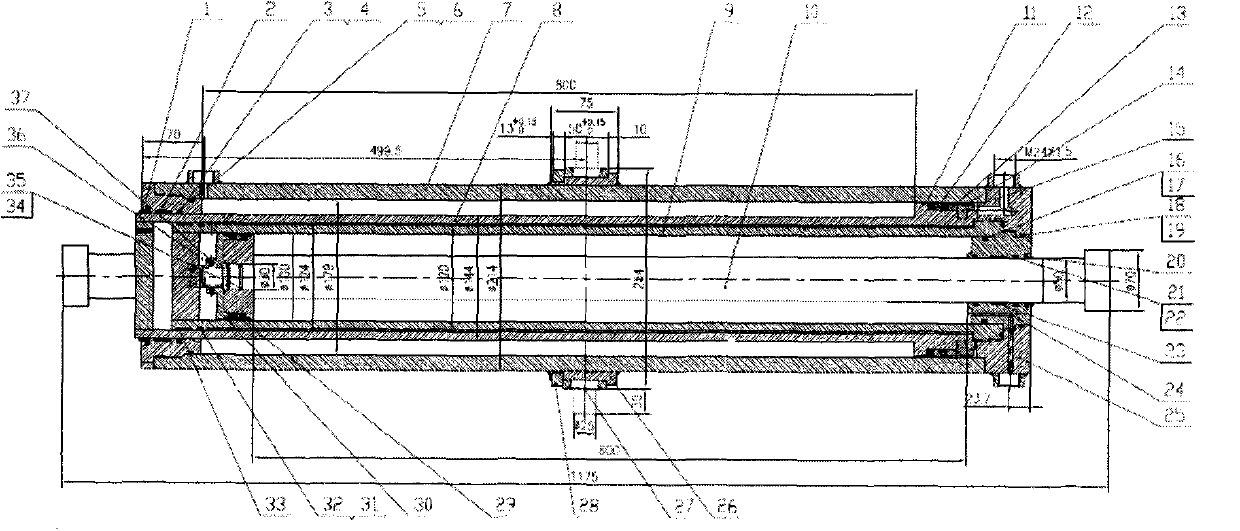

Bidirectional single-flexible hydraulic cylinder

A telescopic hydraulic cylinder and hydraulic cylinder technology, which is applied in the field of hydraulic cylinders, can solve problems such as waste, limited equipment space, and weakened equipment strength, and achieve the effects of reducing the active area, simple structure, and avoiding vicious pressurization effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

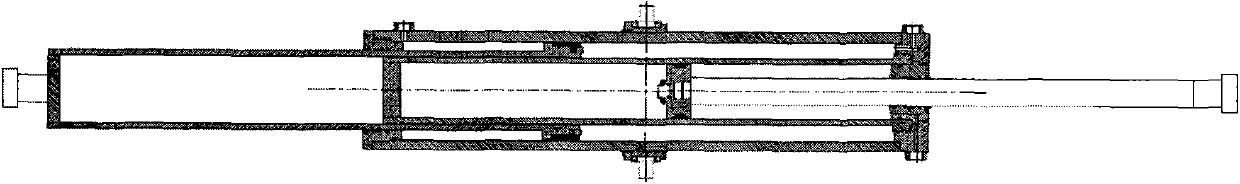

[0015] exist figure 1 In , piston rod 1 (2) is a piston rod that pushes and pulls to the left. Piston rod 2 (4) is a piston rod that pushes and pulls to the right. The lower chambers of the piston rods on both sides are connected, and the upper chambers are independent of each other. In use, the liquid supply to the lower chamber is controlled by the reversing valve, and the opening and closing of the independent upper chamber is adjusted at the same time to realize the push-out action of a single piston rod. By opening the lower chamber, liquid is supplied to each independent upper chamber to realize the pull-back action of the piston rod. After both sides are extended, such as Figure II shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com