Multi-stage compression rate adjustable static sealing test experiment device

A technology for testing experiments and compressibility, which is applied in machine sealing ring testing, liquid tightness measurement using liquid/vacuum degree, and detecting the appearance of fluid at the leakage point, etc. It can solve the problems of leakage measurement accuracy, single test function, Increase the cost and other issues to achieve the effects of leakage detection and measurement, unique leakage channel, and reduced active area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

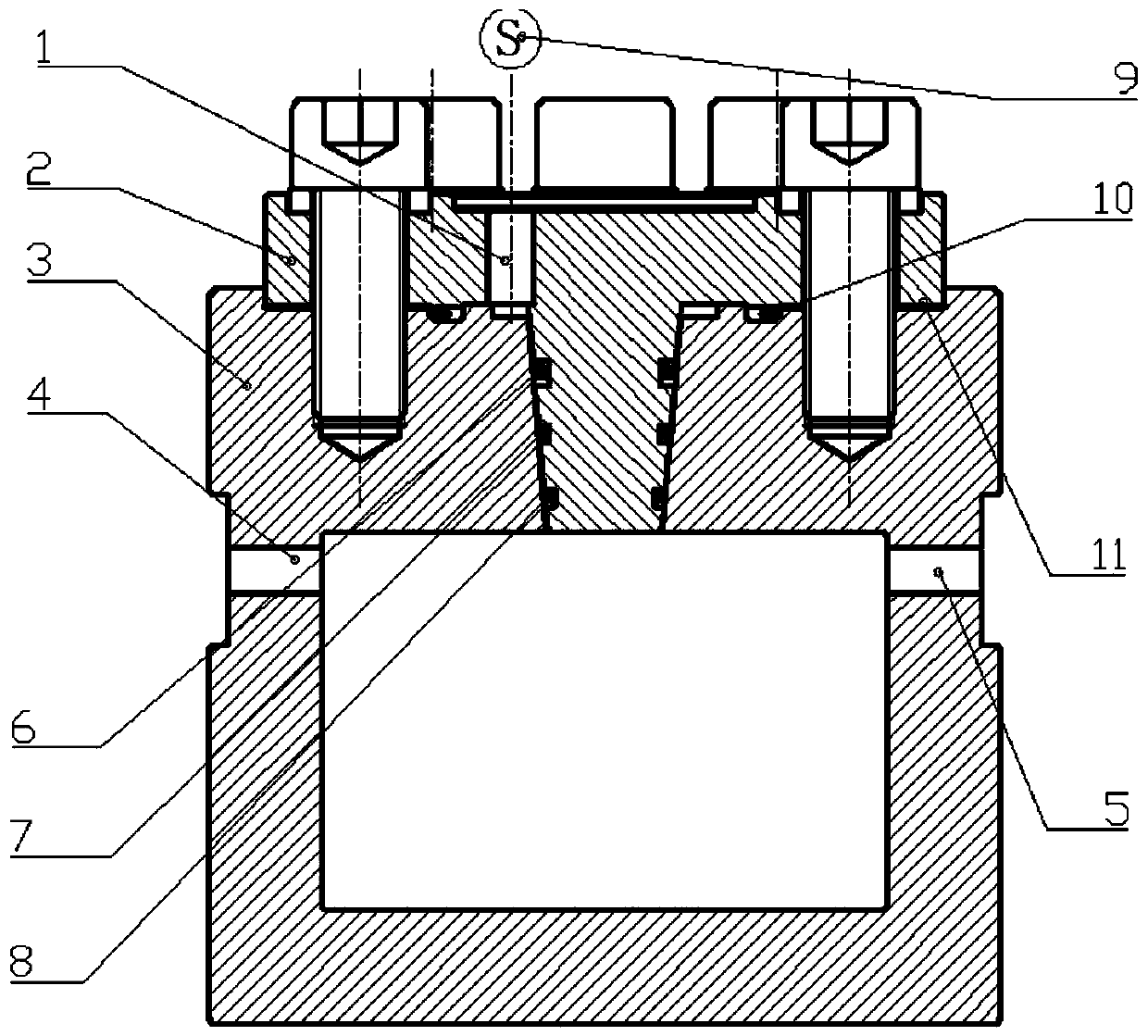

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and examples (illustrated with an O-ring as an example), but the embodiment of the present invention is not limited to this one.

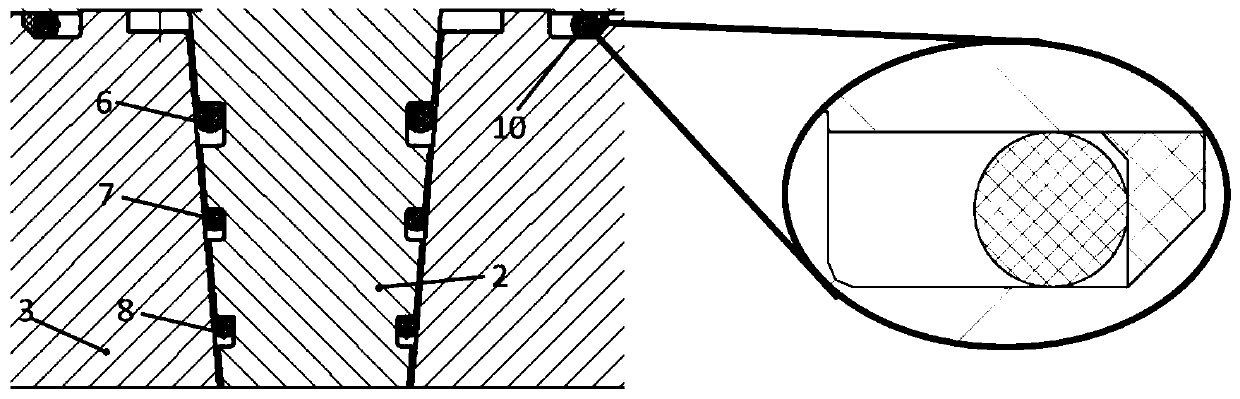

[0022] Such as figure 1 and figure 2 As shown, a multi-stage compressibility adjustable static sealing test experimental device includes an experimental box 3 and a sealing end cover 2, the experimental box 3 is a cylindrical rotary pressure vessel, the cavity is filled with sealing gas, and the sealing end cover 2 It includes a cylindrical cover and a conical boss on the bottom of the cover. The top of the experimental box 3 is provided with a hole matching the boss, and the boss is inserted into the hole. The cover is fixedly connected to the experimental box 3 by screws. top surface.

[0023] Preferably, there is an outer seal 10 between the experimental box body 3 and the cover, and the outer seal 10 is a combined seal of an O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com