Multi-axis laser slot milling machine

A groove milling machine and laser technology, which is applied in laser welding equipment, auxiliary equipment, auxiliary welding equipment, etc., can solve the problems of difficulty in guaranteeing the milling accuracy and processing efficiency of buried grooves, low processing efficiency, etc., and achieve high processing precision The effect of processing efficiency, high processing efficiency and strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

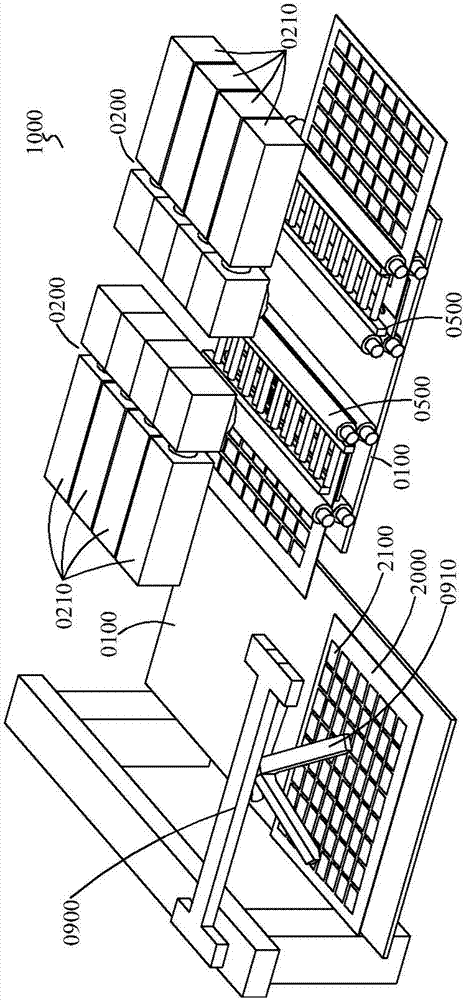

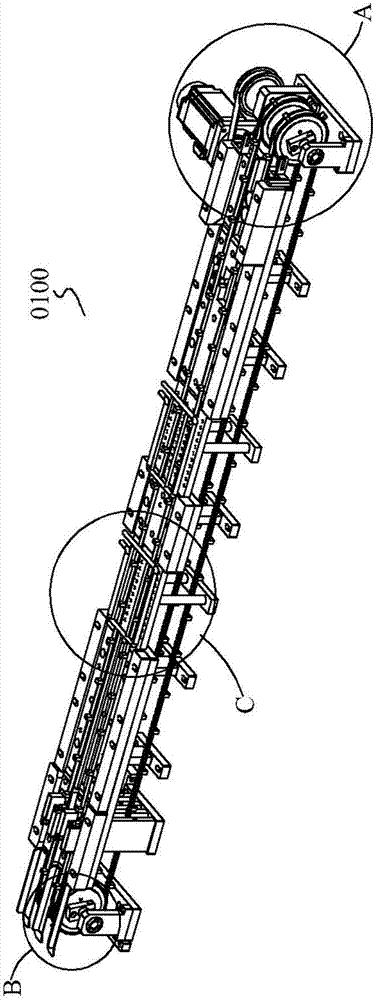

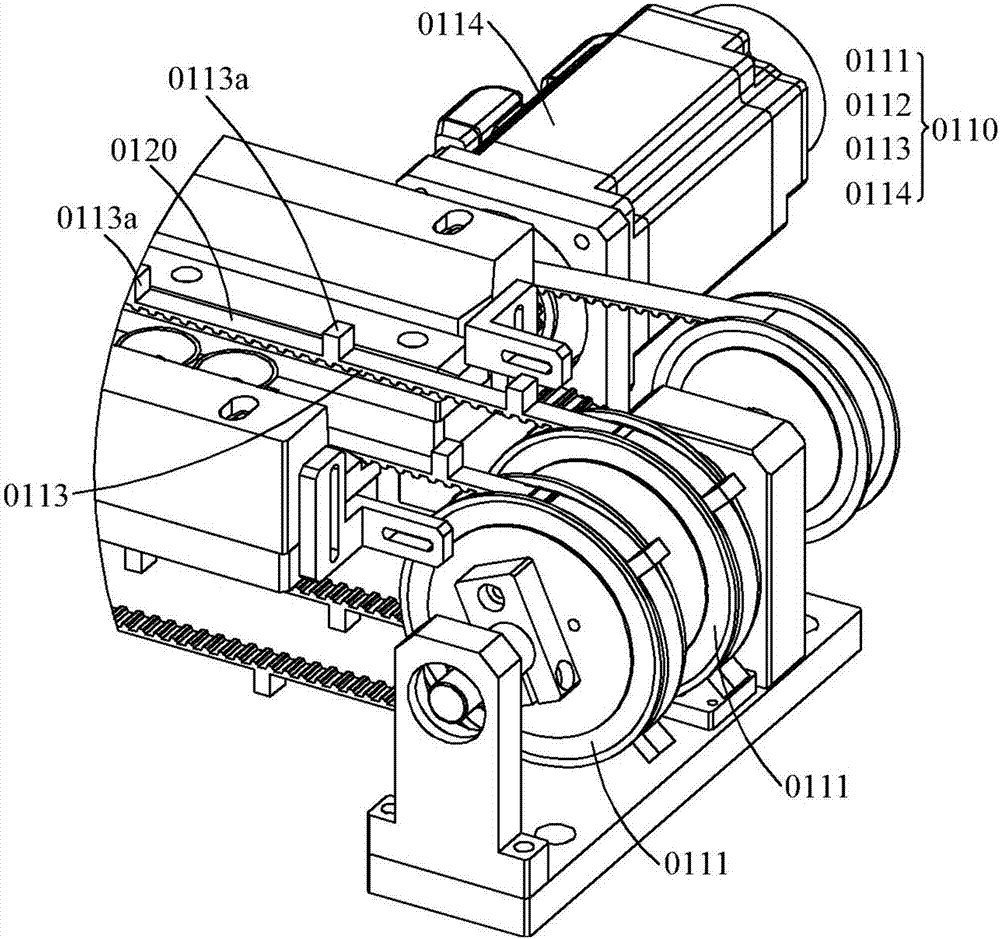

[0039] see figure 1 , the multi-axis laser slot milling machine 1000 includes a conveying mechanism 0100 and a milling mechanism 0200, which is used to provide a processing equipment for laser slot milling of the card base 2100 integrated on the substrate 2000, and has good processing accuracy and processing efficiency. In particular, the milling mechanism 0200 is equipped with a plurality of lasers 0210 and has a multi-axis processing structure, which further improves processing efficiency.

[0040] Wherein, a plurality of card bases 2100 distributed in an array are arranged on the substrate 2000 . The embedding groove of the card base 2100 is used for embedding chips for smart card packaging. The card base 2100 can be arrayed in various ways, such as along the moving direction of the substrate 2000 . Preferably, the plurality of card bases 2100 are distributed on the substrate 2000 at least along a first direction, and the first direction and the moving direction of the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com