Patents

Literature

39results about How to "Add self-locking function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

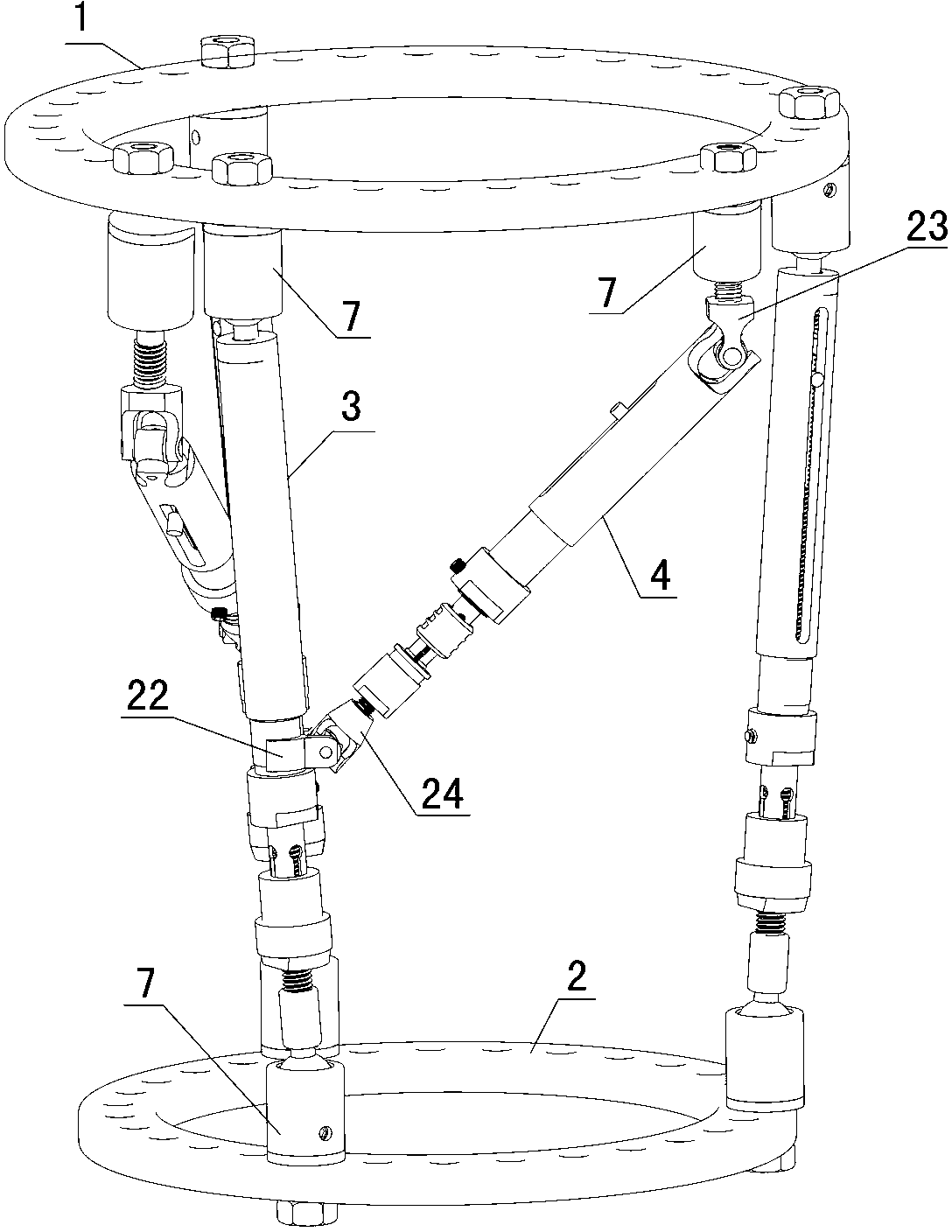

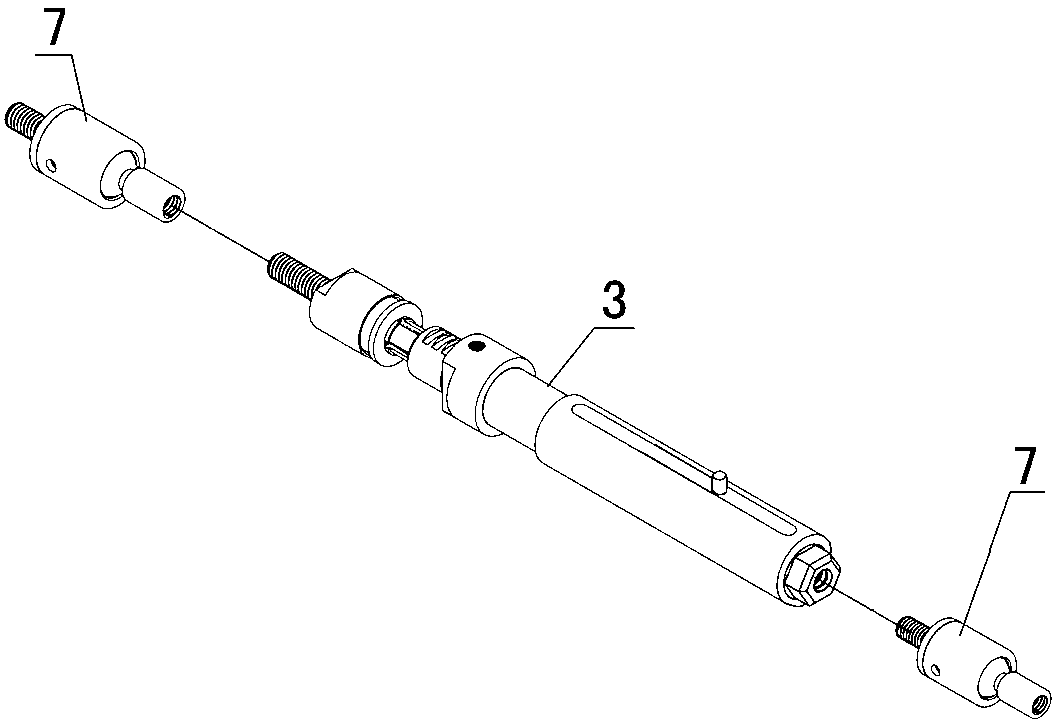

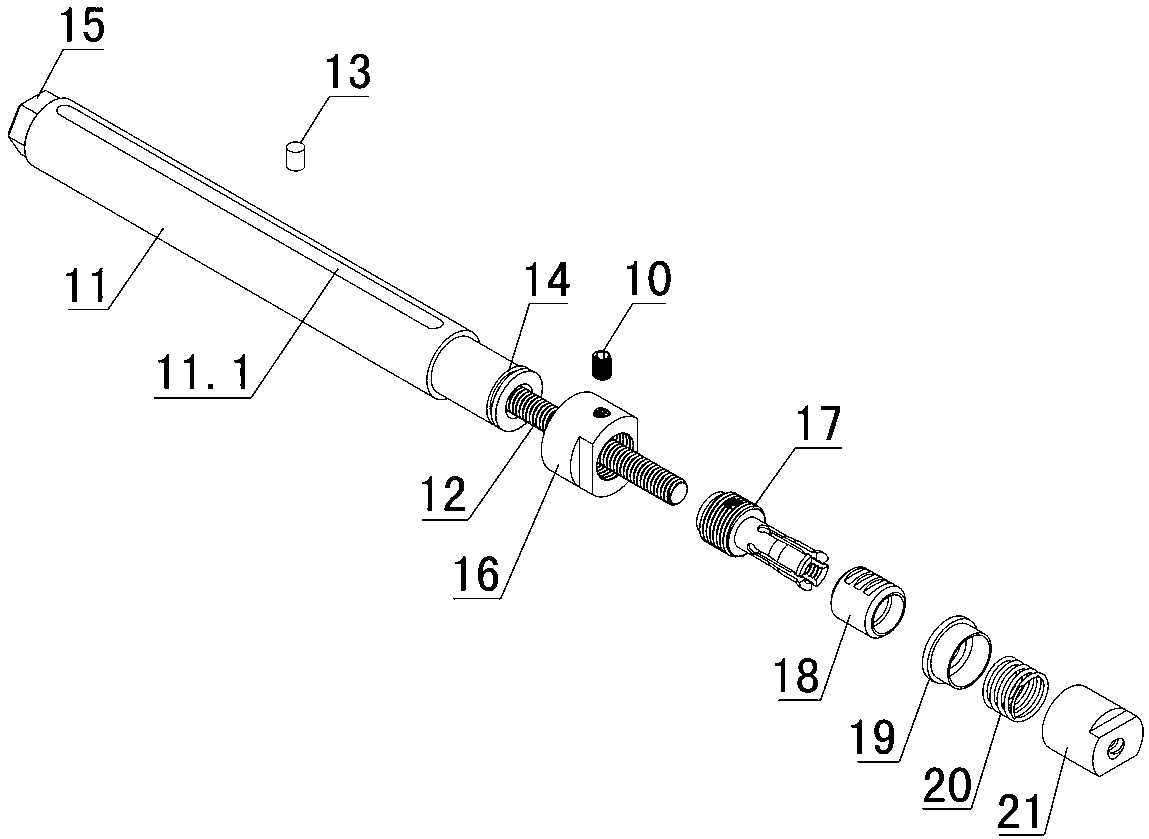

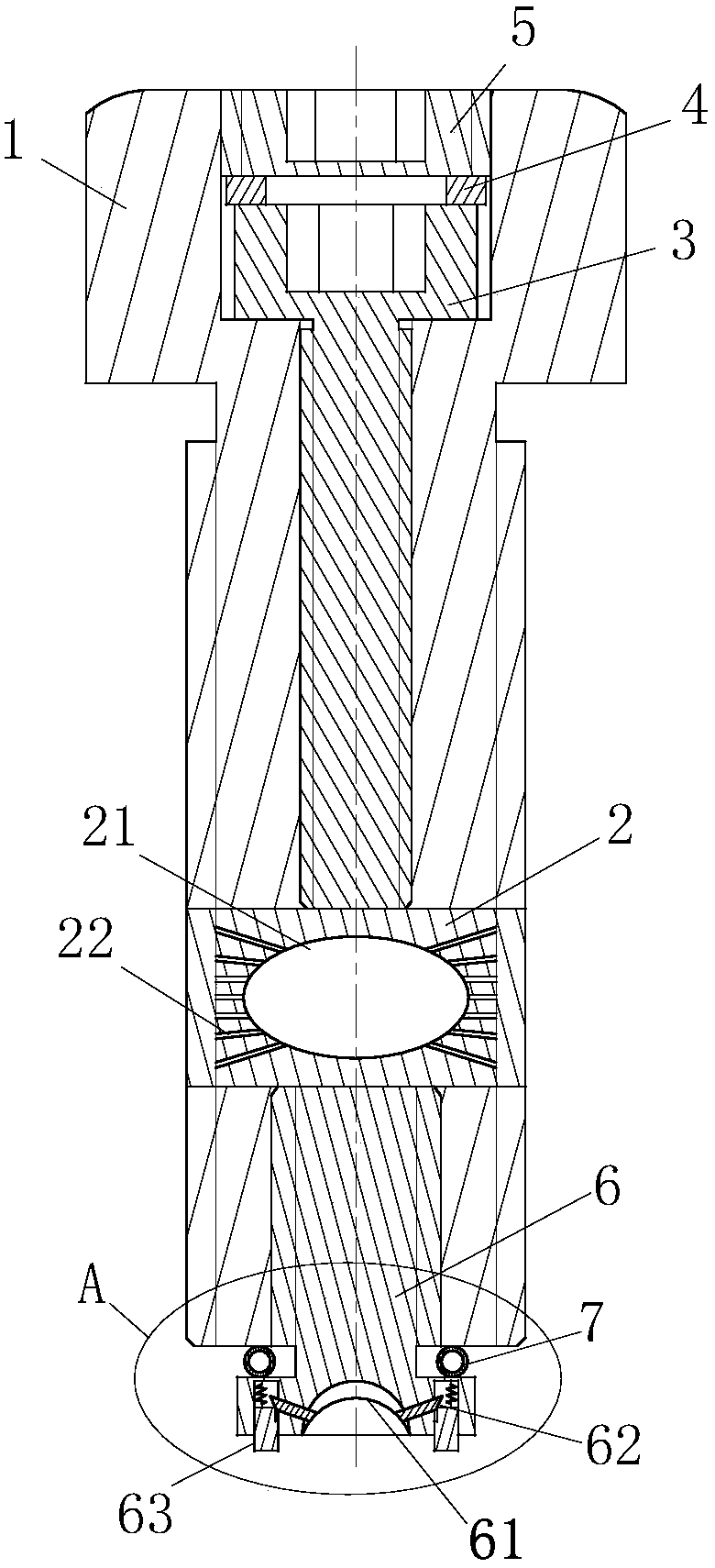

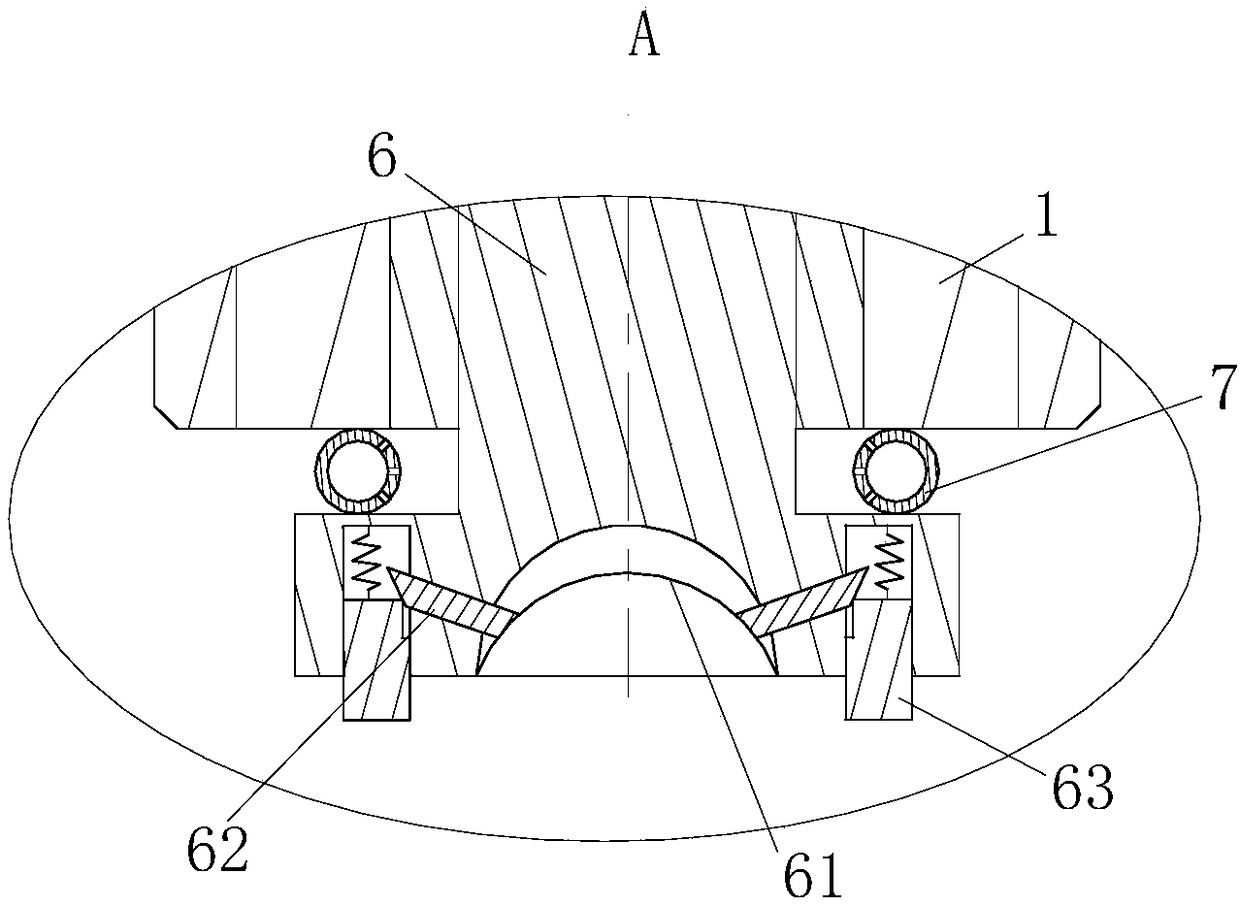

Spherical universal joint for external bone fixator and regulating type bionic external bone fixator

ActiveCN103006302AKeep free spinsAdd self-locking functionExternal osteosynthesisExternal fixatorUniversal joint

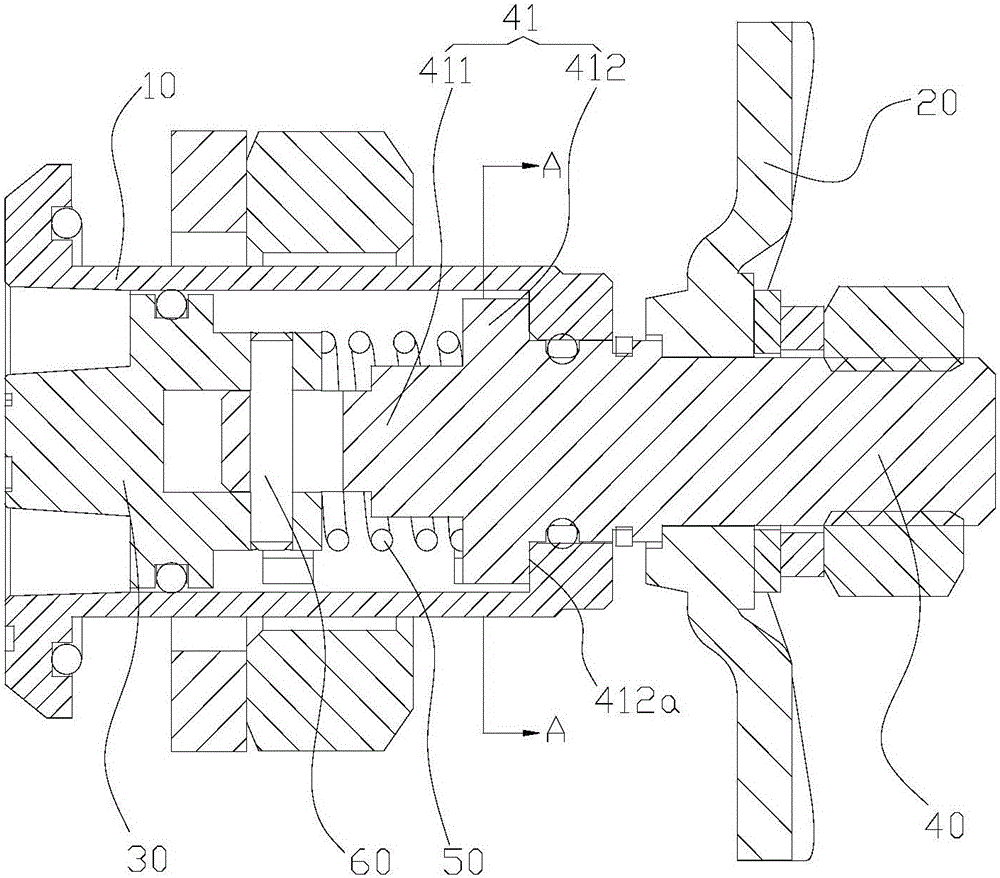

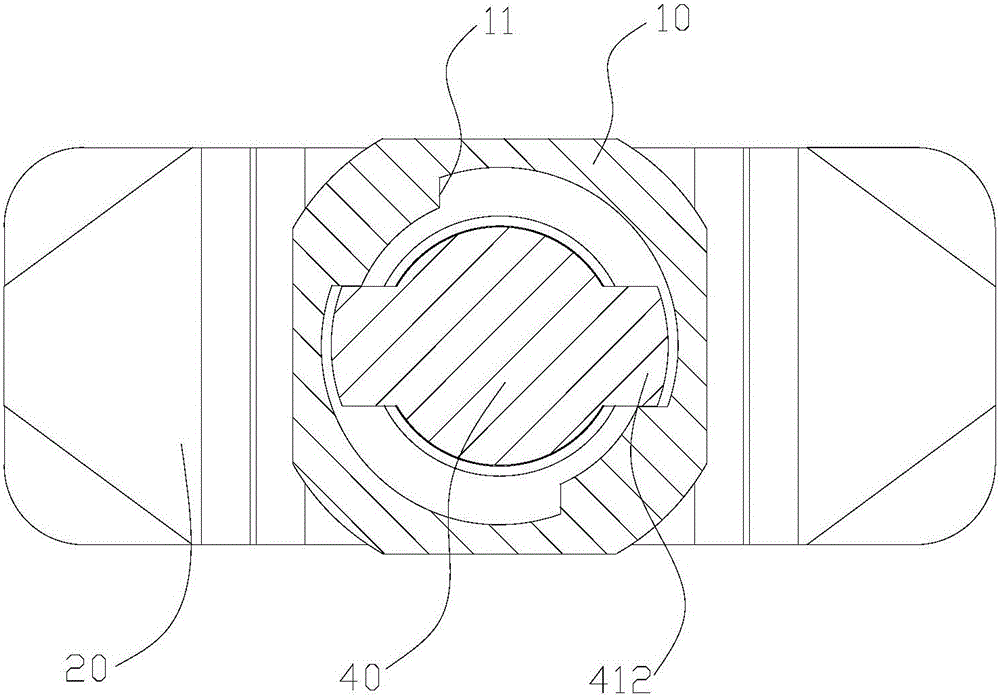

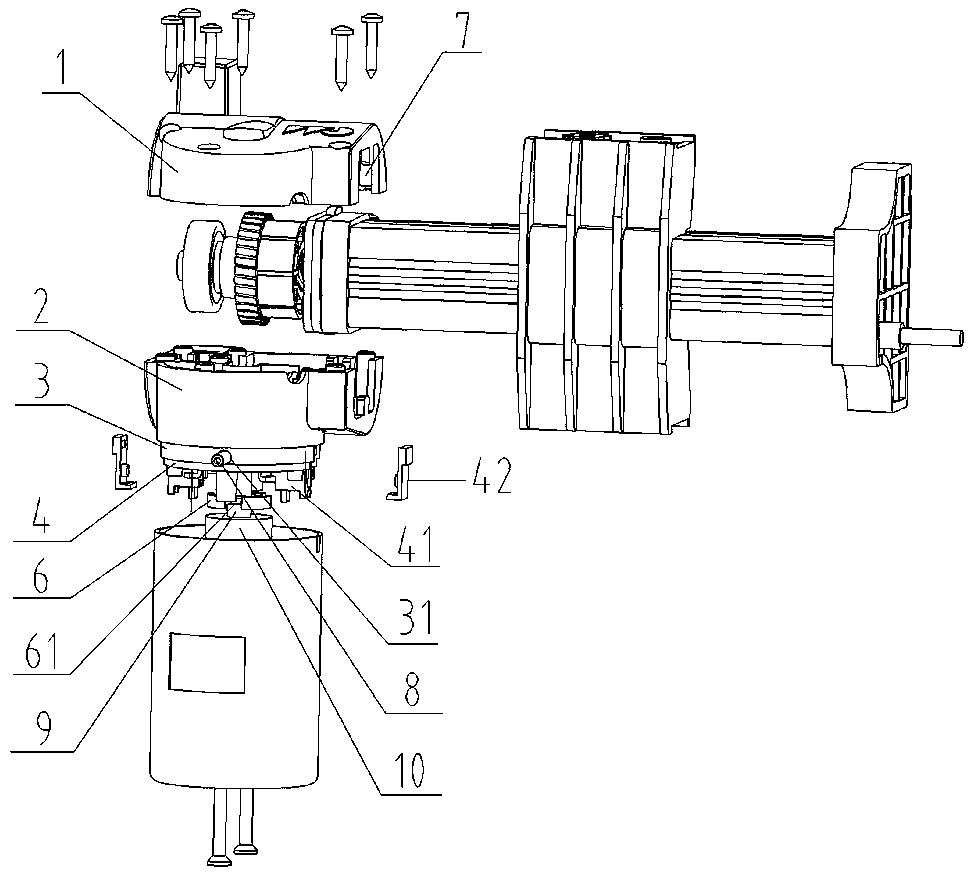

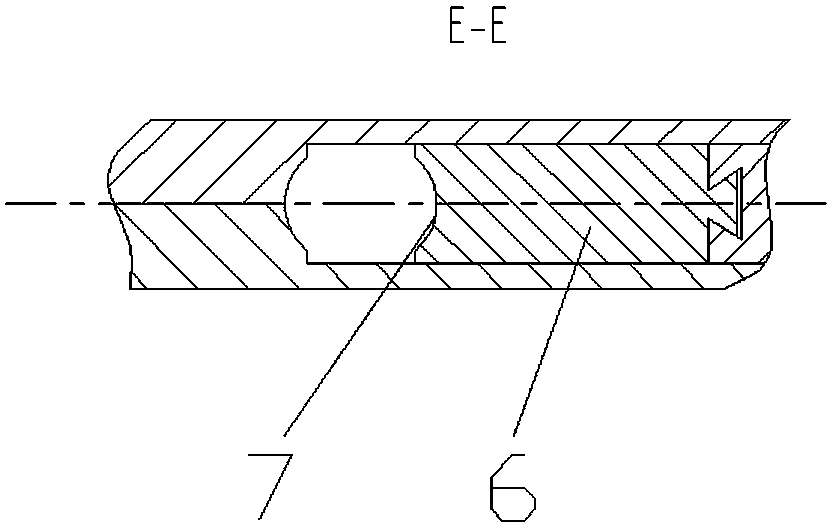

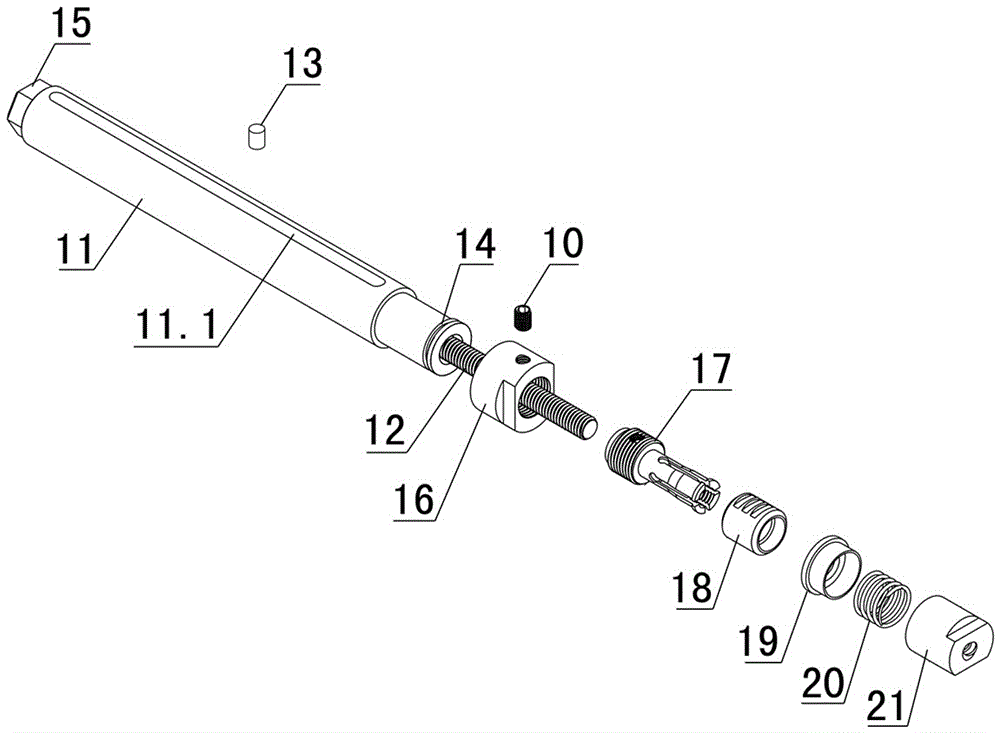

The invention relates to a spherical universal joint for an external bone fixator and a regulating type bionic external bone fixator. The spherical universal joint for the external bone fixator comprises a spherical head, a sleeve, a sleeve cover, a ball slot, a ball bowl, a locking shaft and a locking slide block, wherein the spherical head comprises a joint ball and a threaded type spherical universal joint connector A arranged on the joint ball, the joint ball is arranged on the inner side of the sleeve, the side of the joint ball close to the threaded type spherical universal joint connector A is contacted with the arc-shaped surface of the sleeve, the threaded type spherical universal joint connector A extends out of one end of the sleeve, the sleeve cover is fixedly connected with the other end of the sleeve, the outer side face of the sleeve cover is provided with a threaded type spherical universal joint connector B, and the inner side face of the sleeve cover is provided with a groove for arrangement of the locking slide block. The regulating type bionic external bone fixator with the spherical universal joint has the advantages of simple structure, light weight, low cost, regulating capability and flexible operation, and targeted and personalized combination and regulation can be realized.

Owner:夏和桃

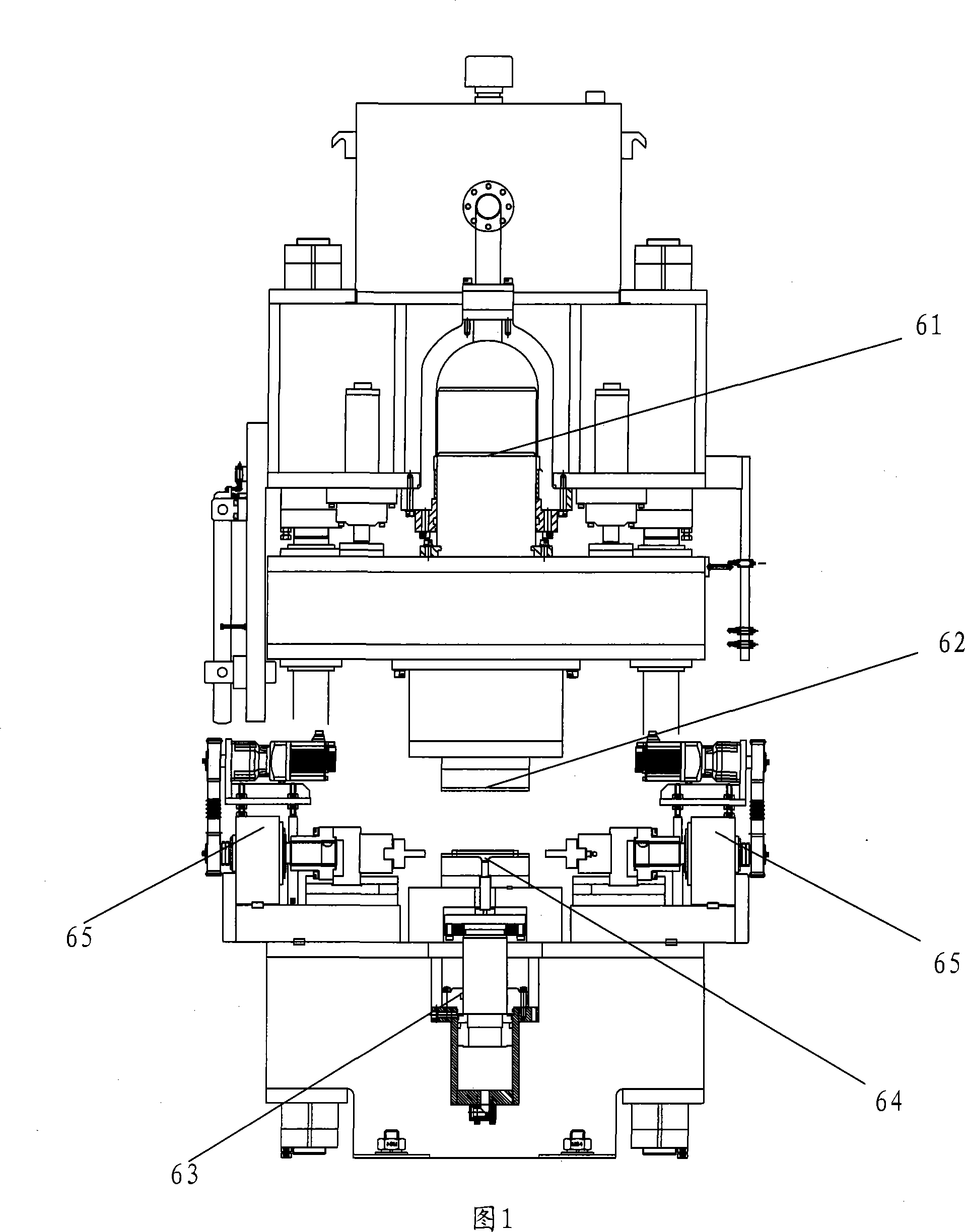

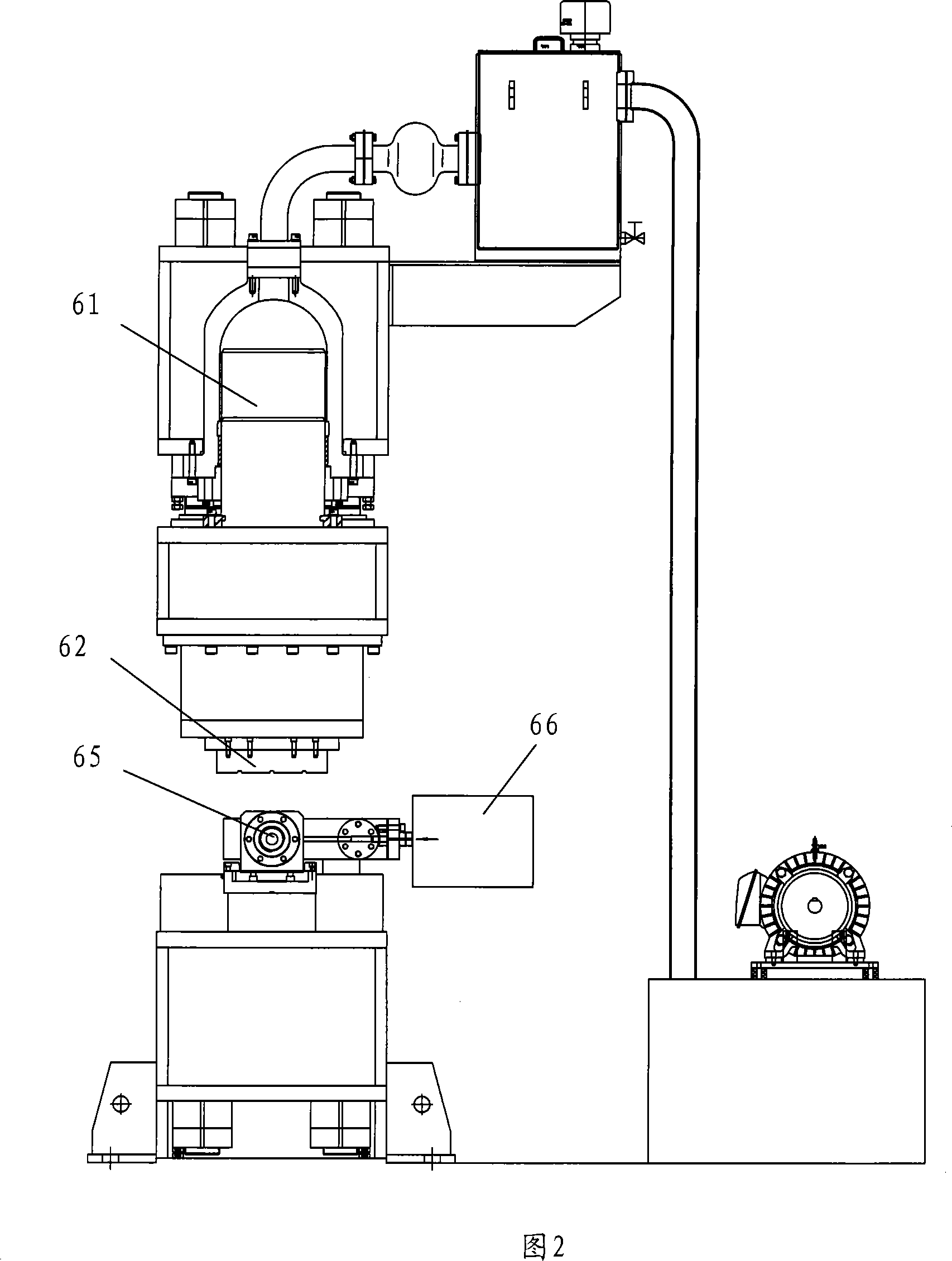

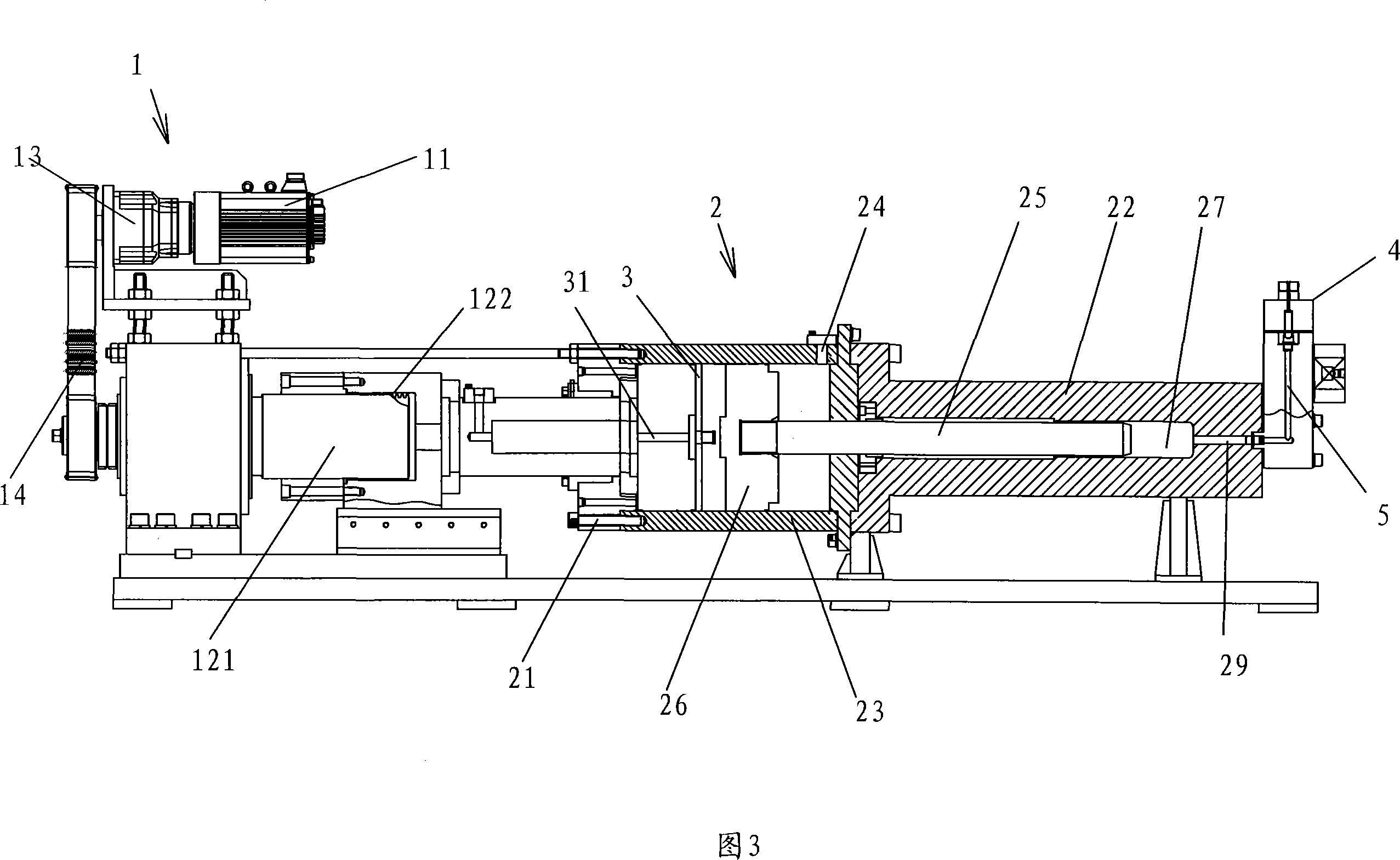

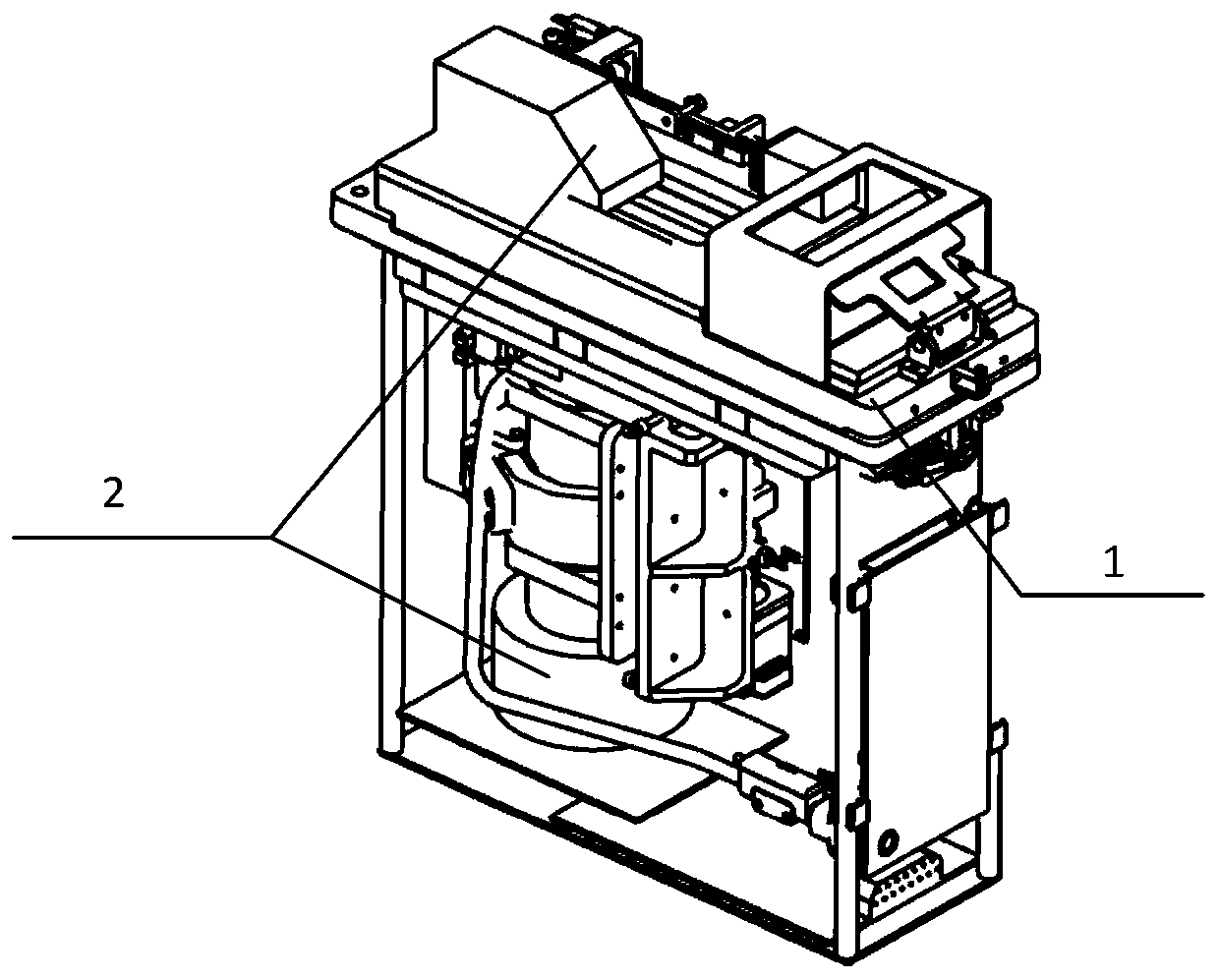

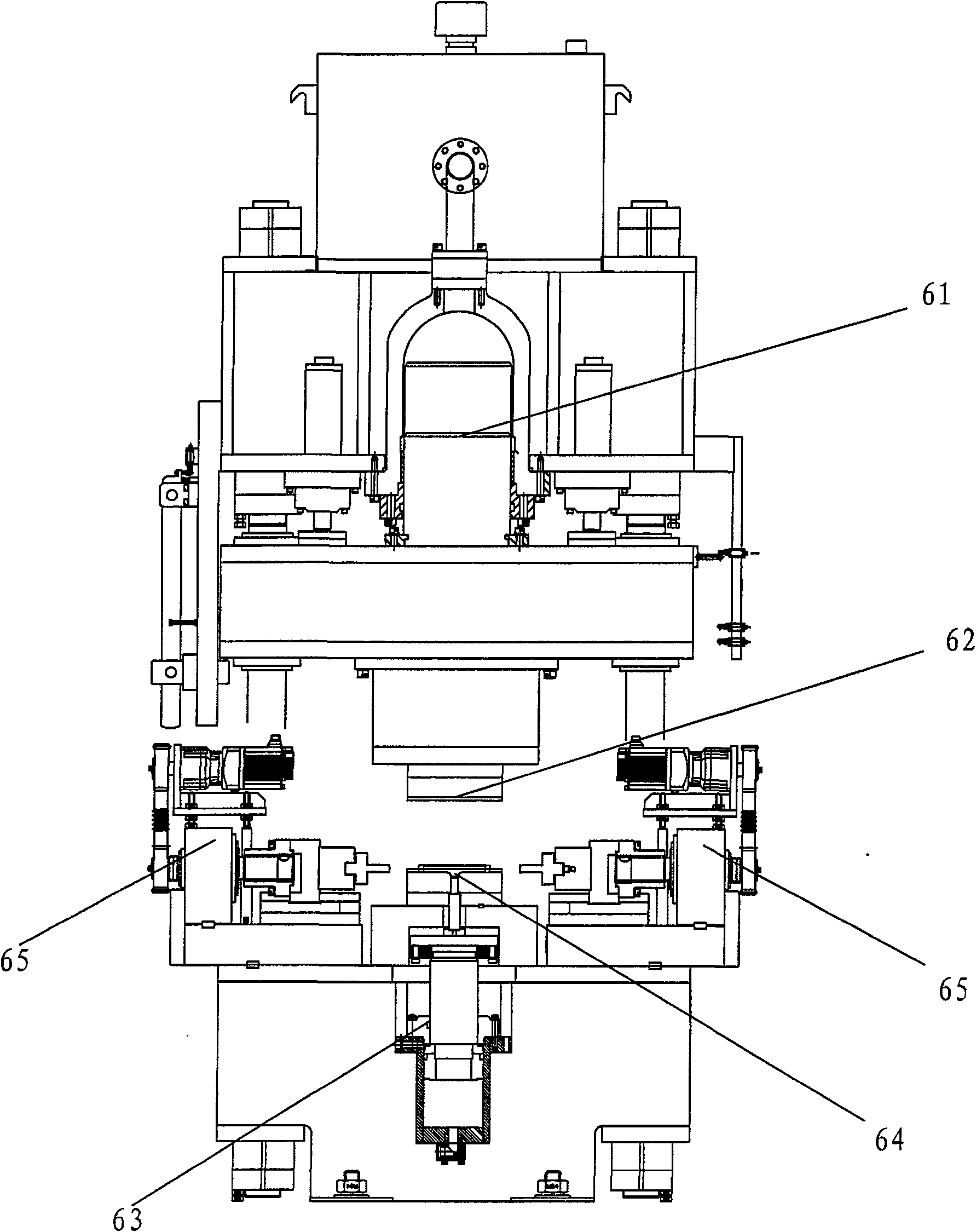

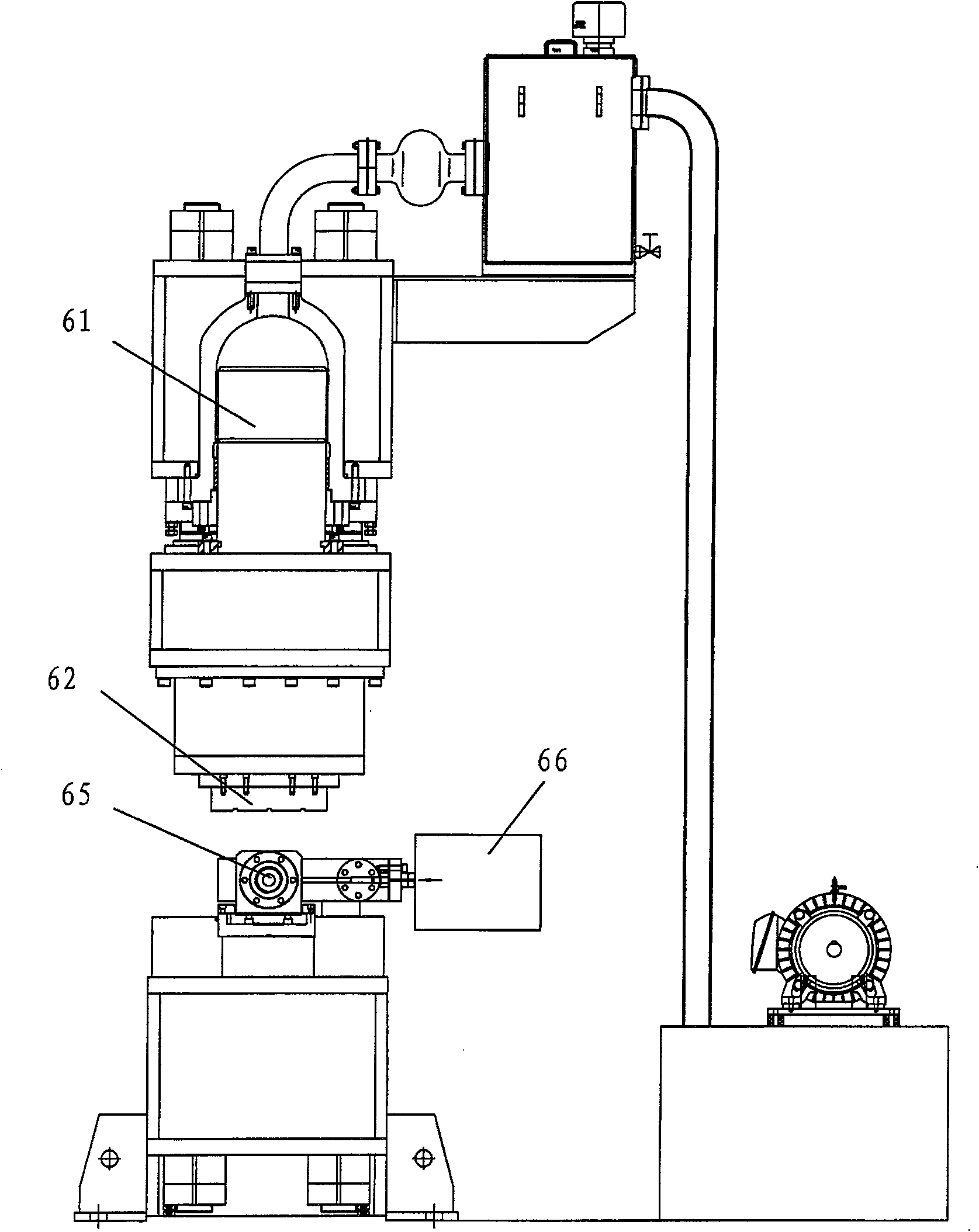

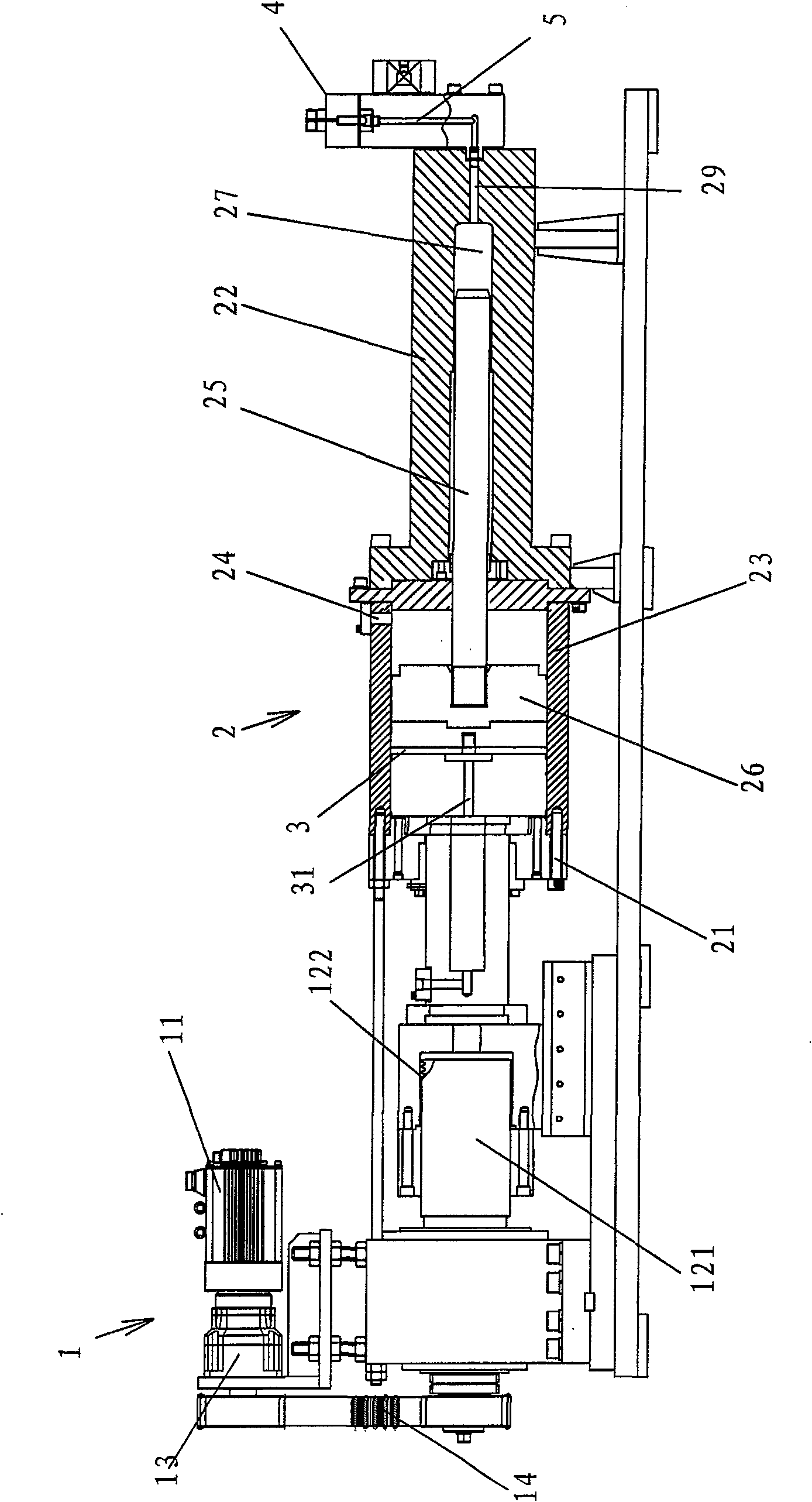

Hydraulic forming equipment

InactiveCN101168179AControl starts wellConvenient timeFluid-pressure convertersQuality of workEngineering

A hydraulic molding device comprises a pressure unit utilized to supply liquid for processed units, the pressure unit comprises a pressure mechanism utilized to increase low-pressure liquid to high-pressure liquid and a driving mechanism which supplies power to the pressure mechanism, the pressure mechanism comprises a first cylinder, the first gas piston inserted in the inner portion of the first cylinder which is capable of sliding, the first gas piston is closely connected with the inner wall of the first cylinder, a liquid storage cavity is formed between the first gas piston and the partial inner wall of the first cylinder, an outlet is positioned on the first gas piston communicated with the liquid storage cavity, the cross-sectional area of the outlet is smaller than that of the liquid storage cavity, the first gas piston is in driving connection to the driving mechanism. The driving mechanism comprises a generator, bolts and cap nuts engaged with the bolts, wherein the optional one of the bolts and the cap nuts is in driving connection to the generator, and direction of movement of the other one is in driving connection to the first gas piston. The utility model is a pressure device with an automatic block system which is convenient to be controlled, and ensures the quality of work pieces in the fluid pressure manufacturing procedure.

Owner:庄添财

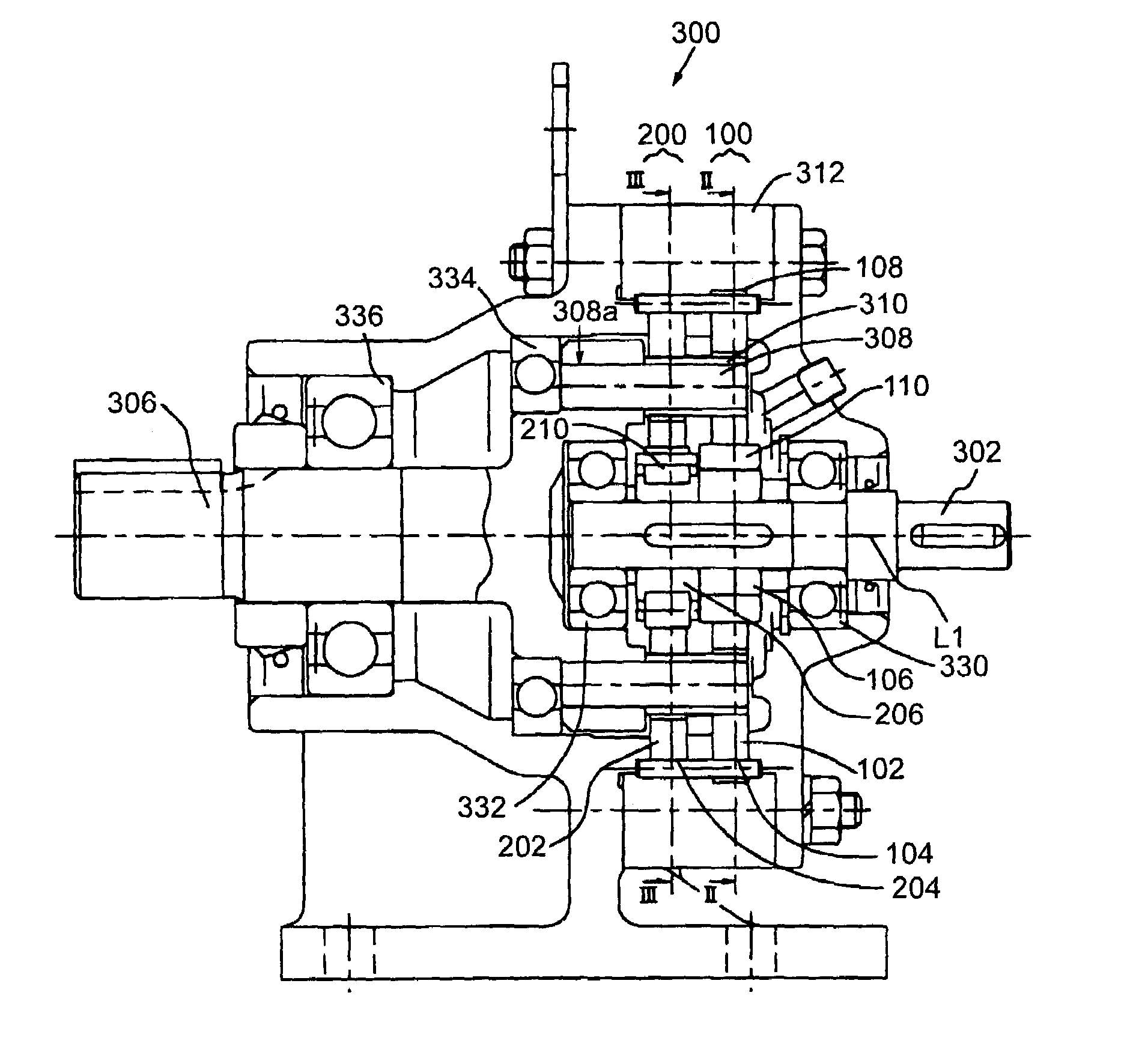

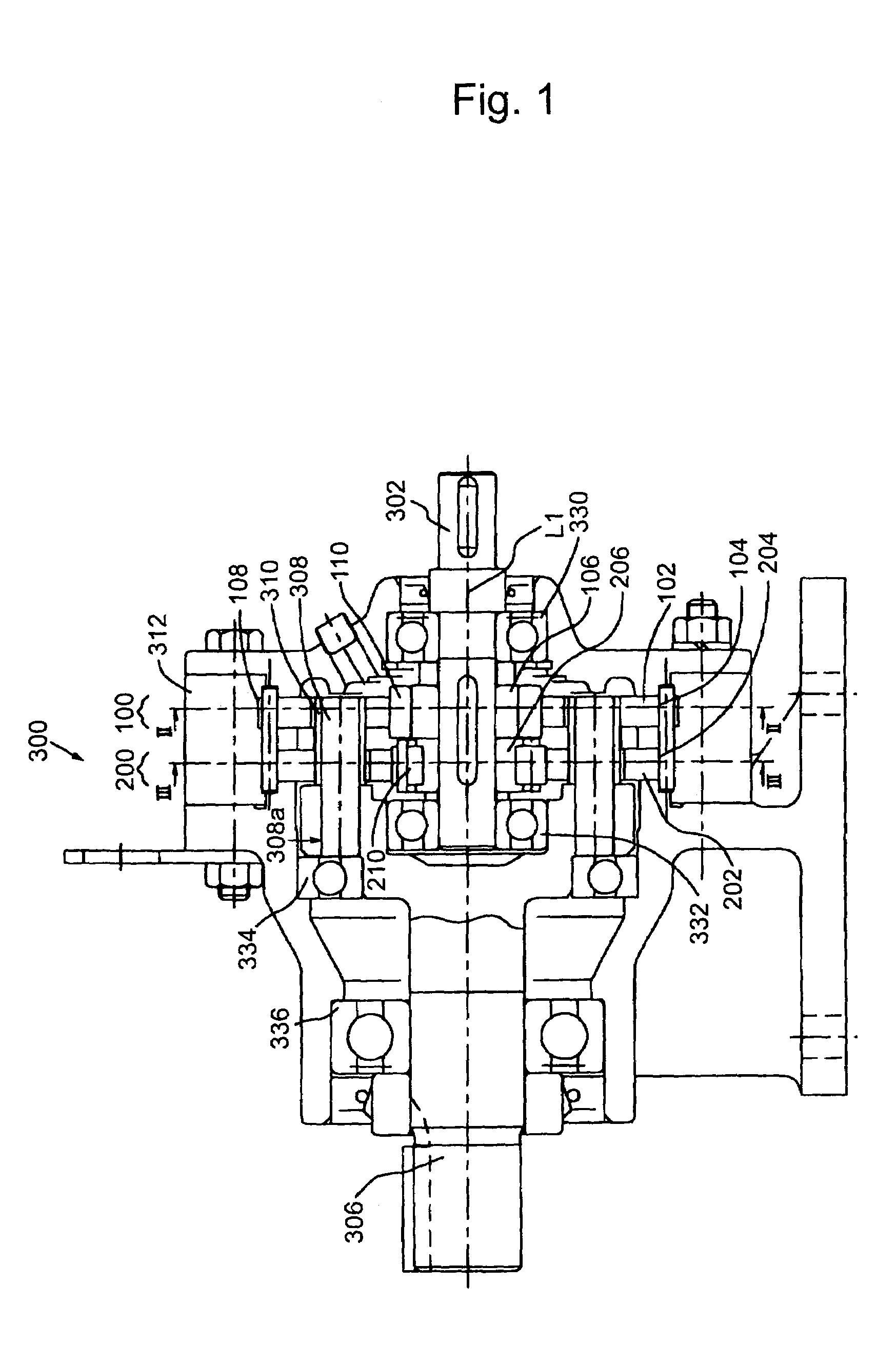

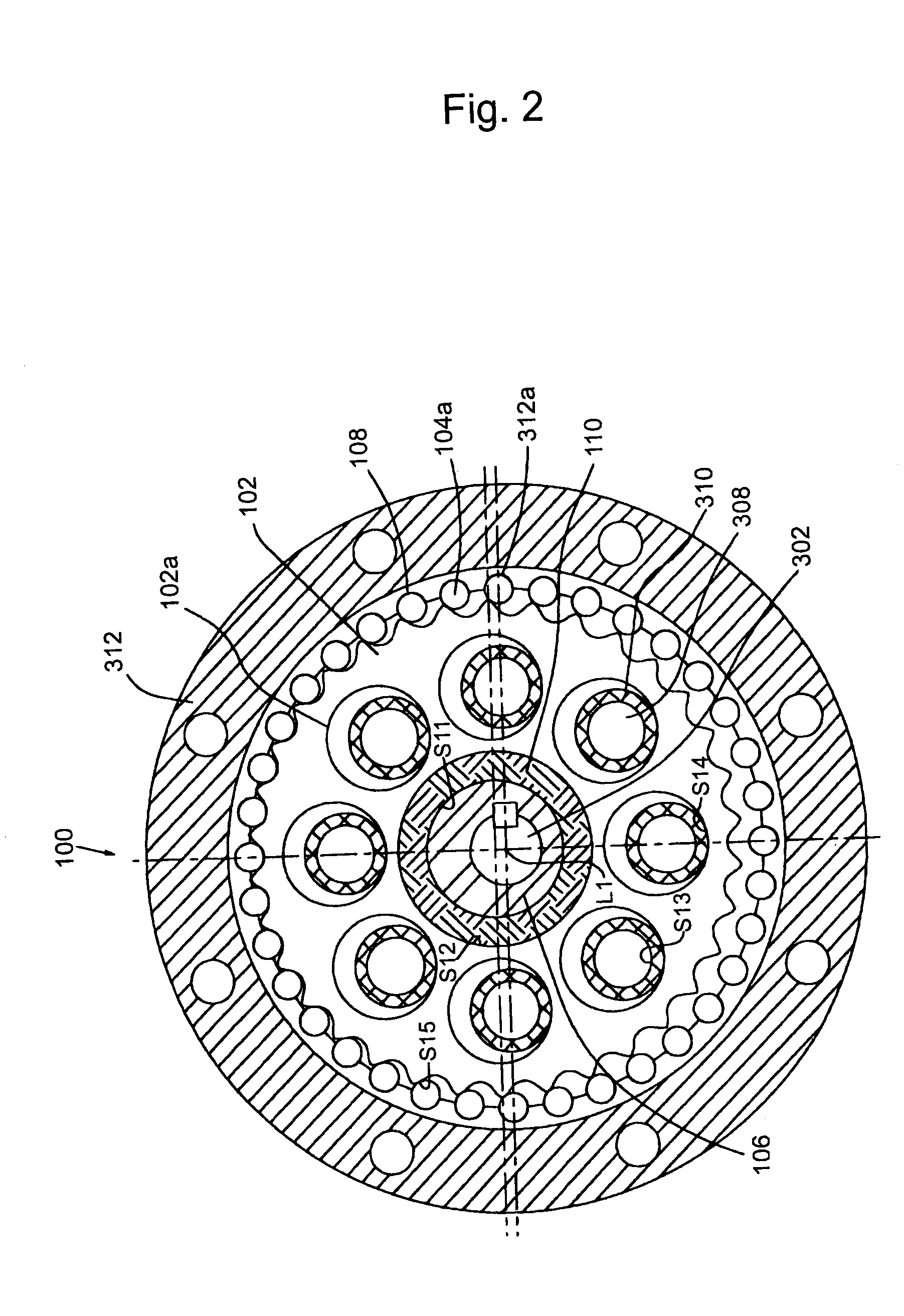

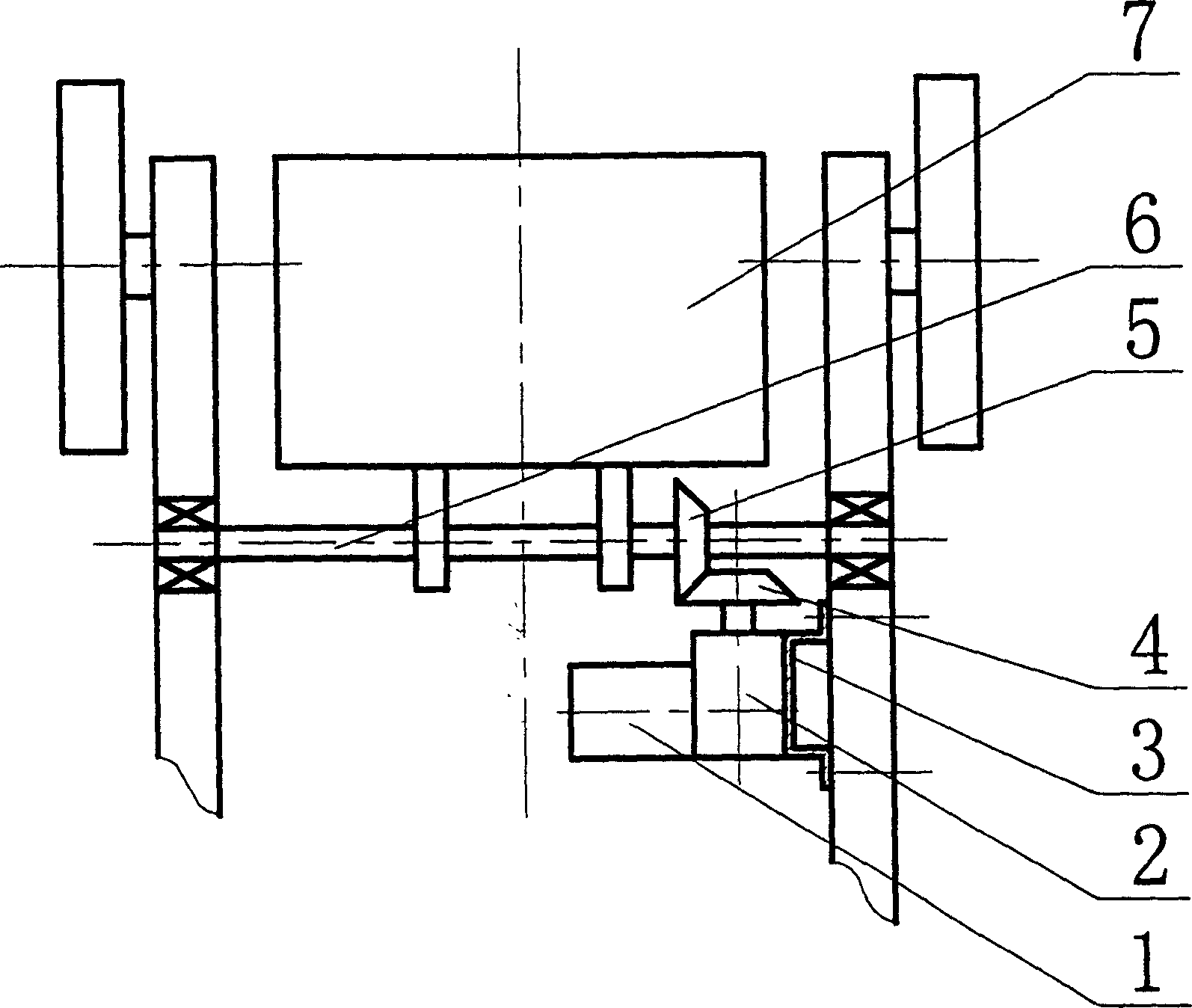

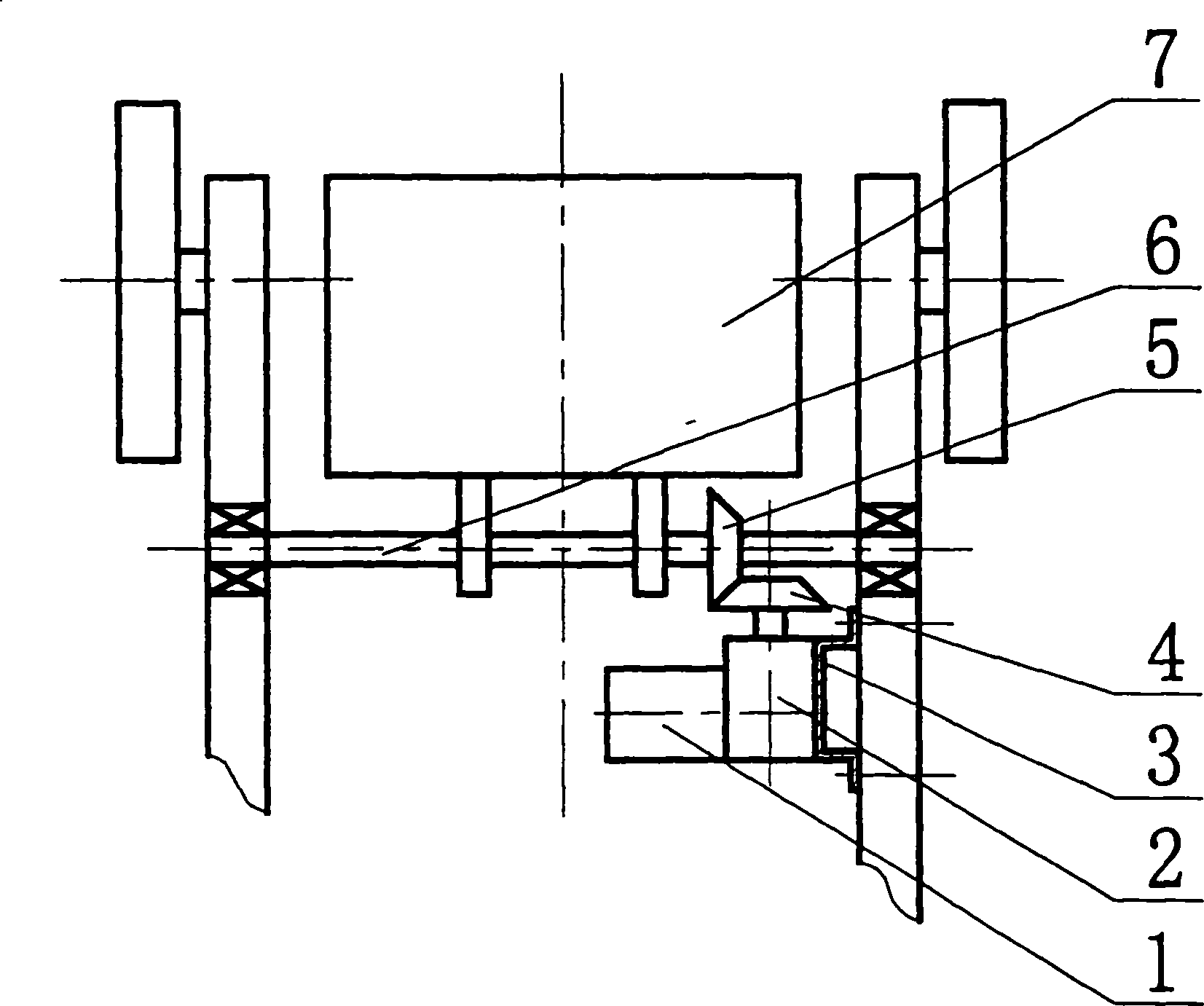

Power transmission device

InactiveUS7147582B2Easy to prepareIncreased Design FreedomToothed gearingsPortable liftingElectric power transmissionGear wheel

It is an object to obtain a power transmission device capable of allowing conflicting needs to coexist rationally and effectively in accordance with a driving situation. As powertransmitting mechanisms of a power transmission device, there are provided a plurality of characteristically-differentiated internally meshing planetary gear mechanisms, each having an external gear and an internal gear having external teeth and internal teeth the difference in the number of teeth between which is slight. In this structure, at least two of the internally meshing planetary gear mechanisms are disposed in parallel on a path of power transmission, and power transmission characteristics of the two mechanisms are designed to differ from each other.

Owner:SUMITOMO HEAVY IND LTD

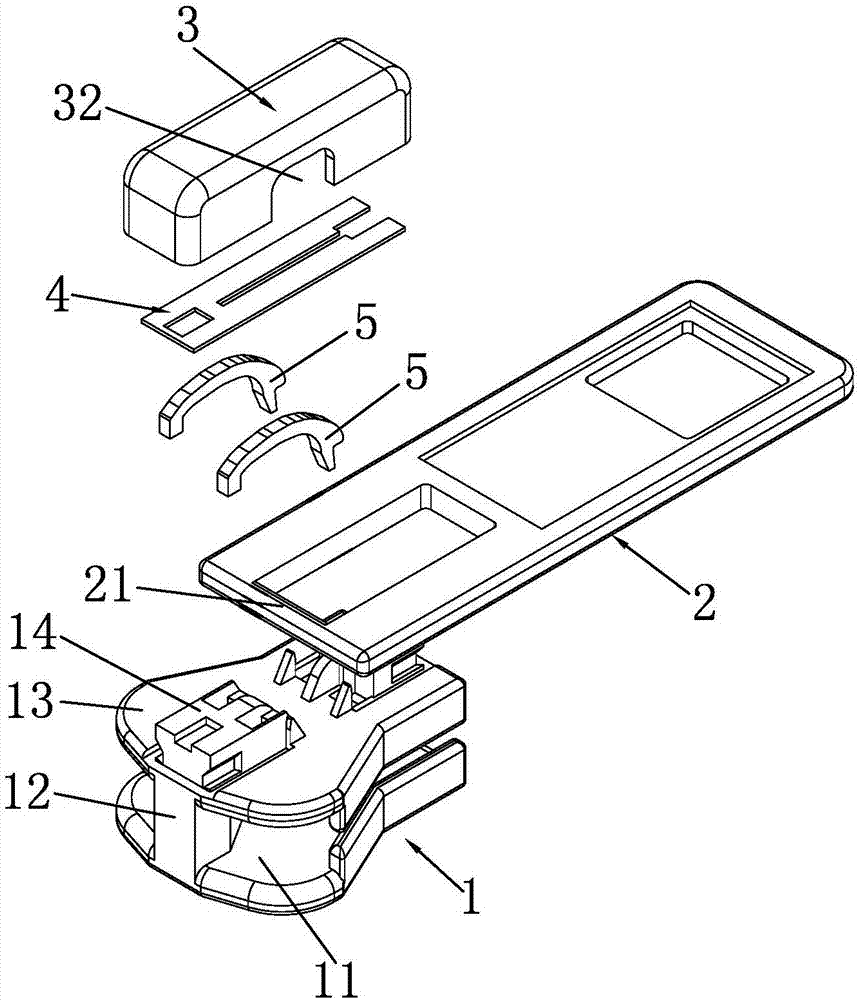

Self-locking bolt

The invention belongs to the technical field of fastening pieces, in particular to a self-locking bolt. The self-locking bolt comprises a first bolt, an elastic module and a second bolt; a first thread hole and a second thread hole are formed in the first bolt; the first thread hole is positioned in the first bolt; the second thread hole is positioned at the lower end of the first bolt; the firstbolt is an external hexagonal bolt; the elastic module is positioned at the middle part of the first bolt; the elastic module adopts a material of spring steel; the elastic module is one part of the first bolt; the first bolt is used for bolt self-locking; the second bolt is an internal hexagonal bolt, and is fixed in the first bolt through the first thread hole; the lower end of the second bolt is contacted with the upper end of the elastic module; and the second bolt is used for extruding the elastic module.

Owner:GUANGZHOU BAOSTEP IND LTD

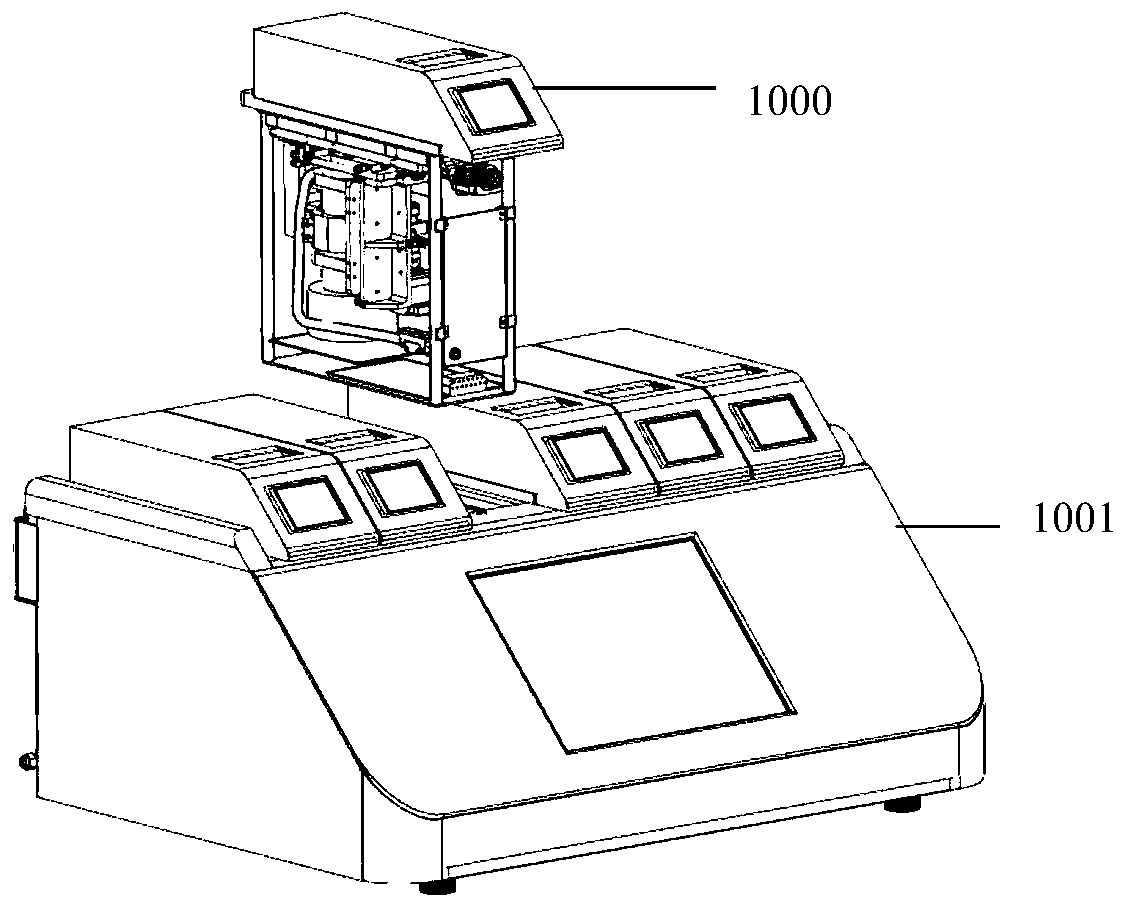

Embryo time difference cultivation device

PendingCN110129201ALess cumulative exposure timeIncrease success rateBioreactor/fermenter combinationsBiological substance pretreatmentsPhysicsCumulative Exposure

The invention discloses an embryo time difference cultivation device comprising at least one independent time difference cultivation module for culturing samples, wherein the time difference cultivation module comprises a cultivation module and a microscopic imaging system. The microscopic imaging system comprises a light source and a correspondingly matched imaging device. The light source is located at the upper part of the cultivation module, and can move independently in the horizontal axis direction. The imaging device is located at the lower part of the cultivation module, can move independently in the horizontal axis direction parallel to the movement trajectory of the light source, also can move independently in the vertical axis direction perpendicular to the movement trajectory of the light source. Embryos are in independent cultivation spaces, the cultivation environments are independent with each other, and the fetching and placing of the embryos do not interfere with eachother; the embryos do not need to move in the cultivation process and normal development is not interfered; each embryo is photographed independently, and the cumulative exposure time is less.

Owner:济南国科医工科技发展有限公司

Reversible bucket

InactiveCN1539723AIncreased discharge rangeNo inversionLoading/unloadingManipulatorReduction driveReducer

An overturnable scopper is composed of motor, worm-gear speed reducer and its holder fixed to swinging arm of robot, bevel gear A fixed to output shaft of speed reducer, rotary axle, bevel gear B fixed to said rotary axle, and scooper fixed to said rotary axle.

Owner:SHANGHAI JIAO TONG UNIV

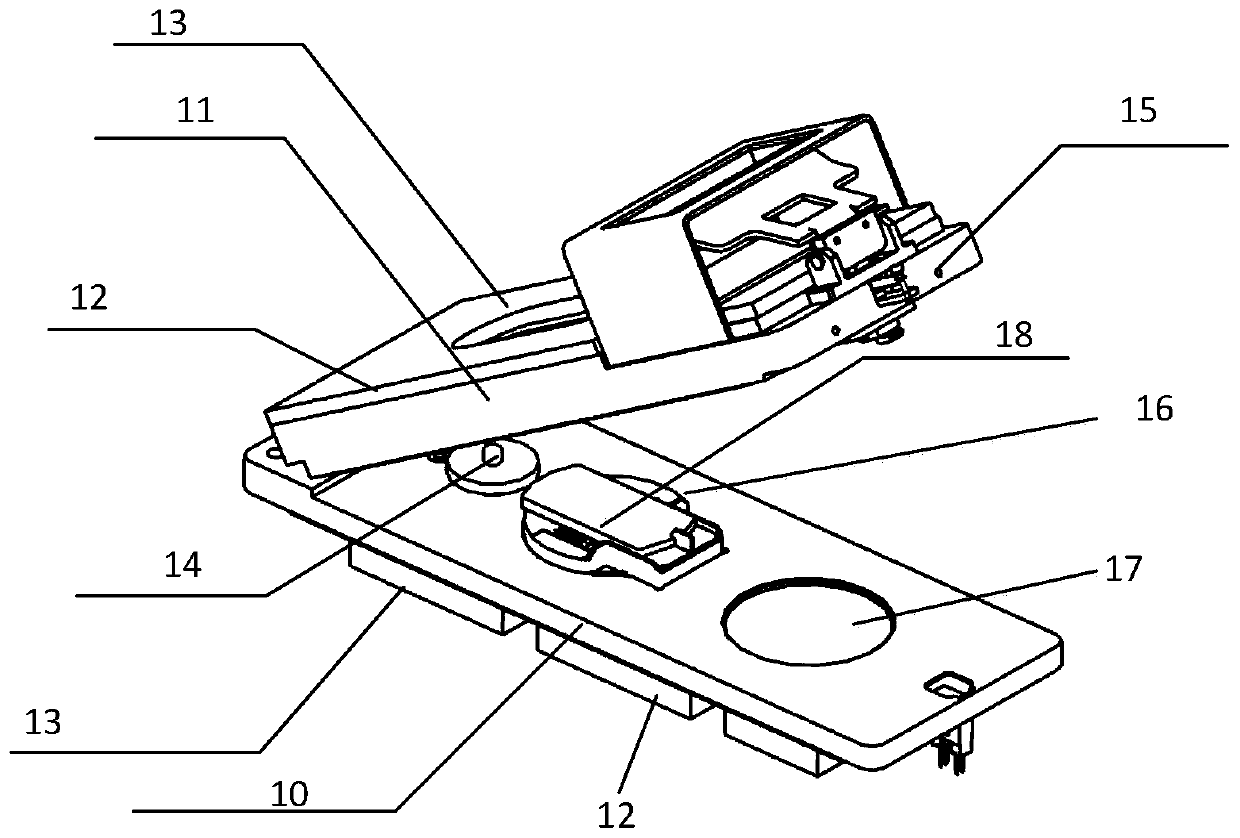

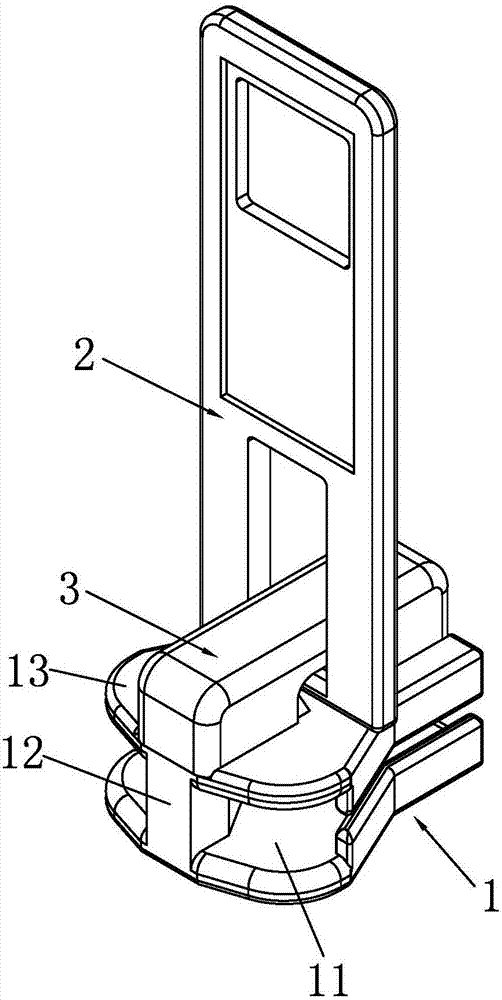

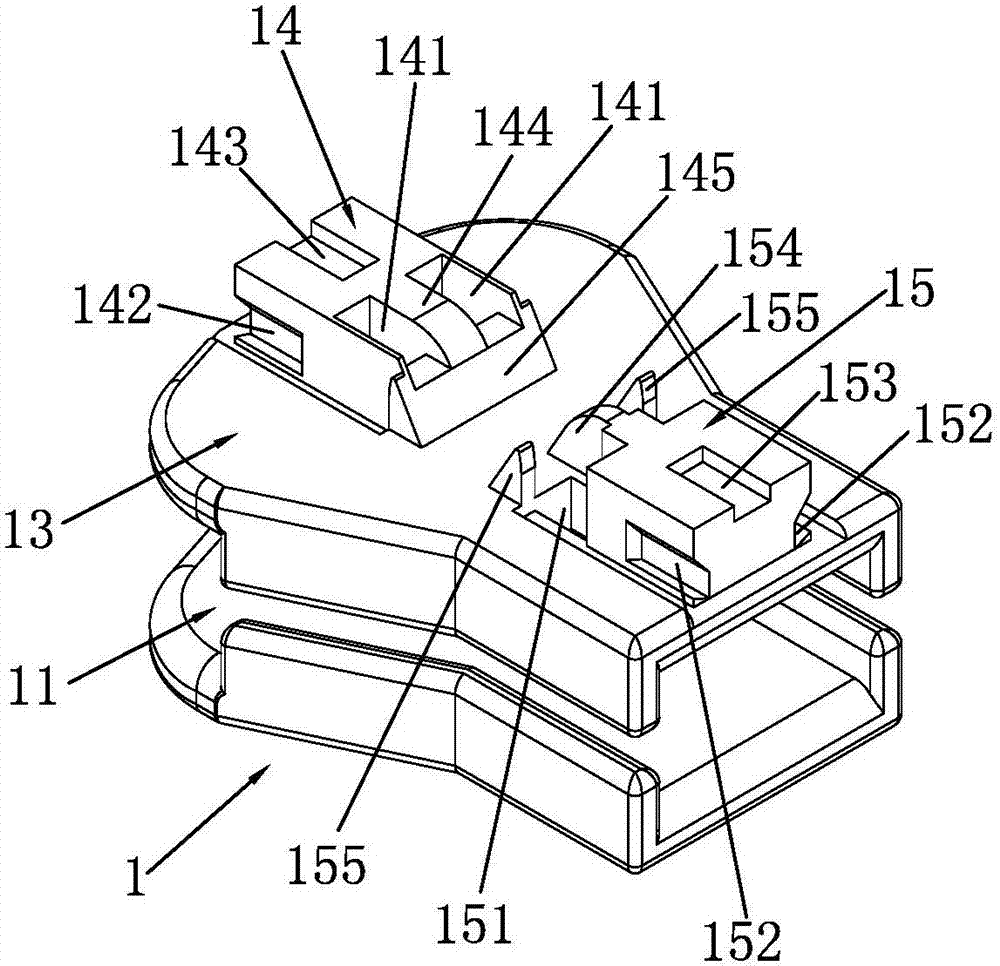

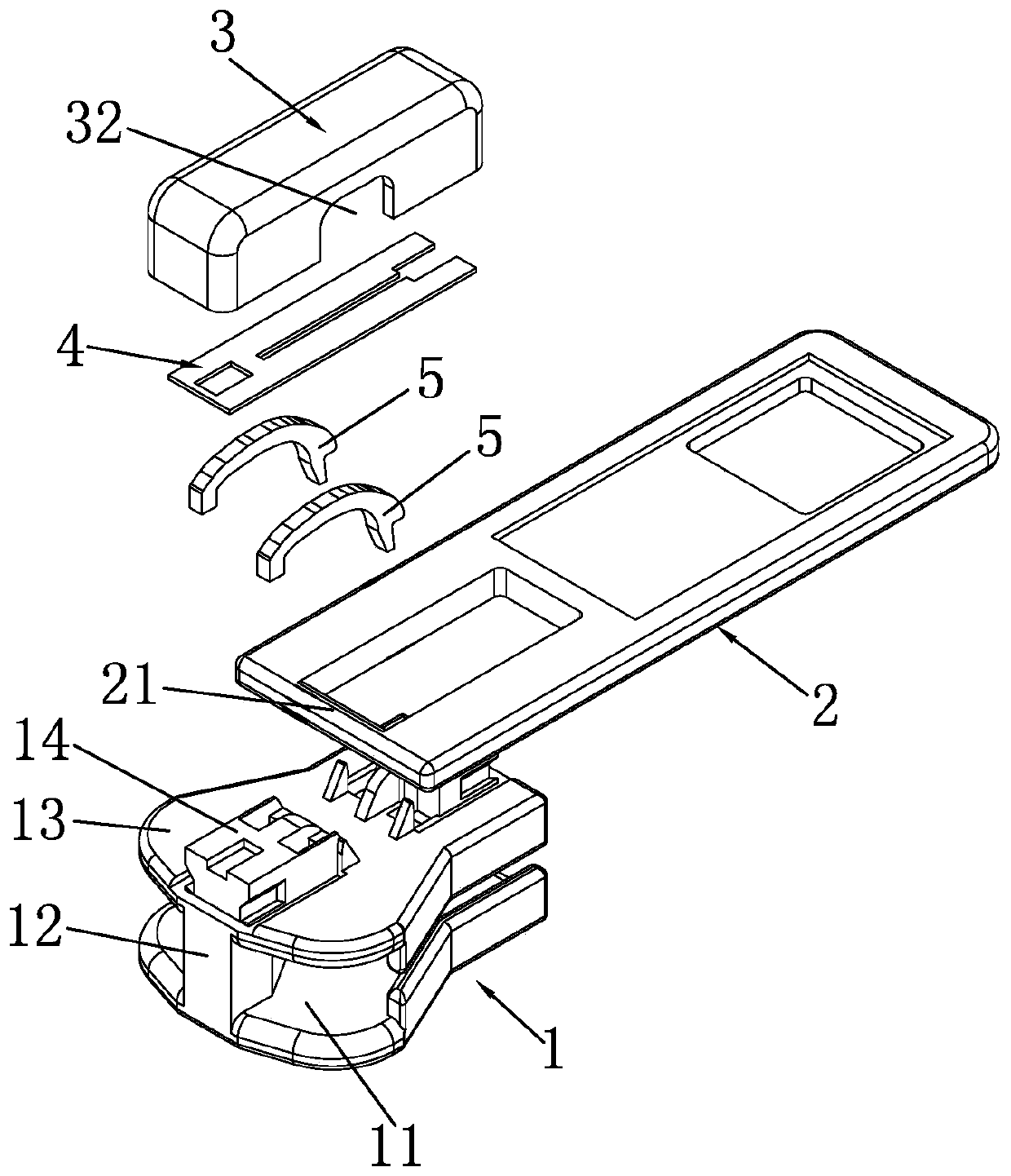

Self-locking puller with double horse hooks

ActiveCN107183846AAdd self-locking functionNot easy to damageSlide fastenersArchitectural engineeringSelf locking

The invention provides a self-locking puller with double horse hooks. The self-locking puller comprises a puller body, a pulling sheet, a cap, an elastic sheet, and two horse hooks, the puller body is constituted by making a lower wing plate, a guide pillar and an upper wing plate connected, a front installation part and a rear installation part are arranged at the top surface of the upper wing plate, two first installation holes are formed in the front installation part, and two second installation holes are formed in the rear installation part; first connecting clamping grooves are formed in both the left side wall and the right side wall of the front mounting part, and second connecting clamping grooves are formed in both the left side wall and the right side wall of the rear mounting part; a first positioning groove is formed in the top of the front installation part, and a second positioning groove is formed in the top of the rear installation part; an opening groove is formed in the middle of the elastic sheet, and the elastic sheet is separated into a left elastic sheet and a right elastic sheet, and the left elastic sheet and the right elastic sheet are symmetrically arranged; loading lugs are arranged at the top end of the inside of the cap. In the elastic sheet of the self-locking puller, two mutually independent elastic parts are arranged to correspond to the two horse hooks, when the left elastic sheet and the right elastic sheet apply acting force to the corresponding horse hooks to achieve self-locking of the puller, the left elastic sheet and the right elastic sheet are not interfered mutually, and thus the self-locking function of the puller is sharply promoted.

Owner:FUJIAN SBS ZIPPER SCI & TECH CO LTD

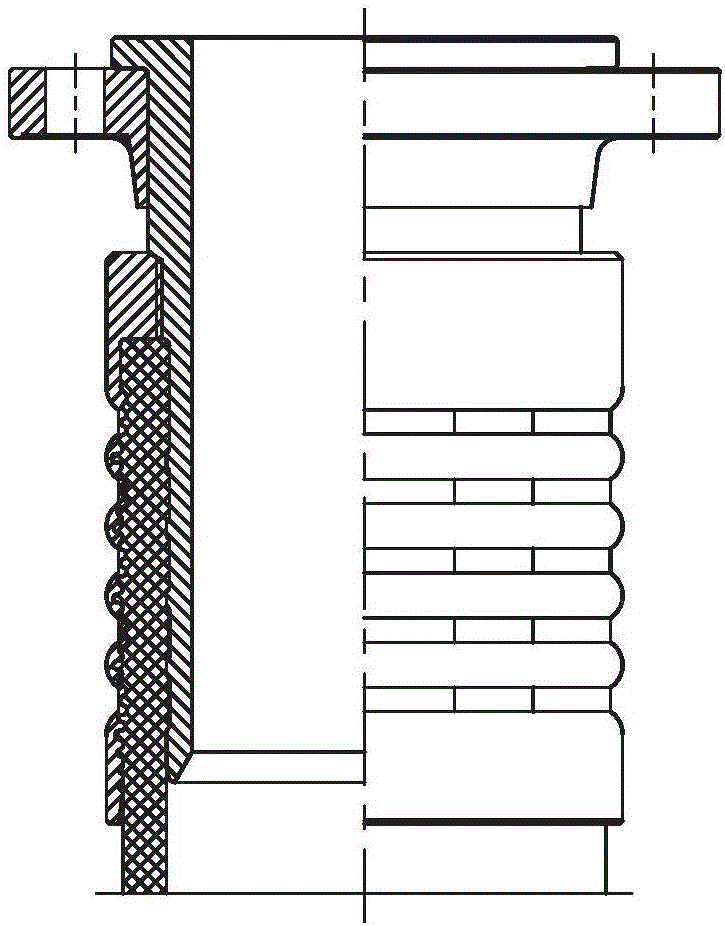

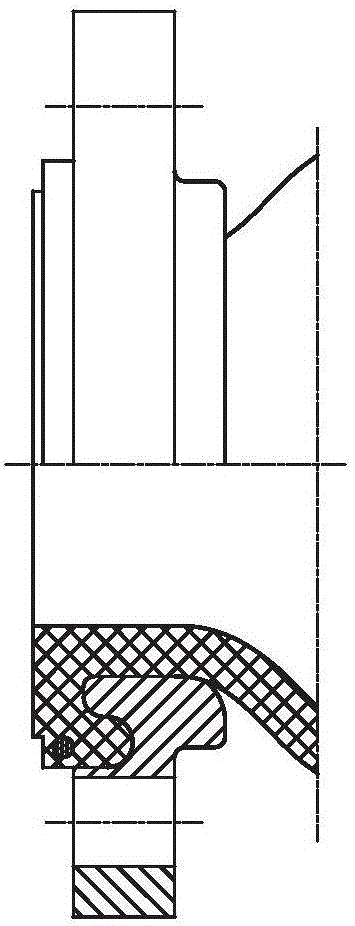

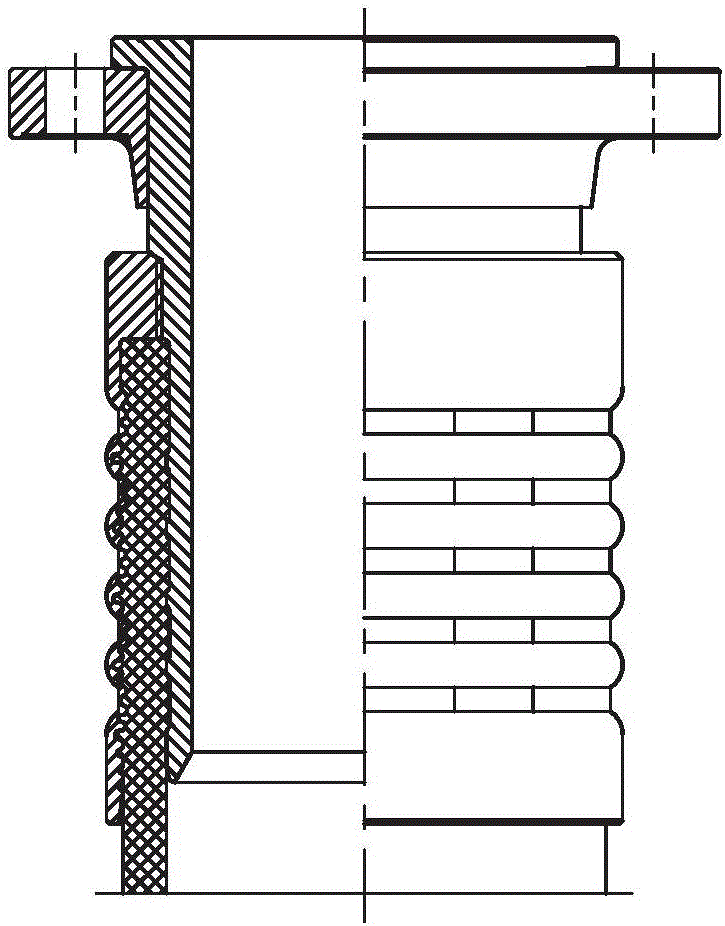

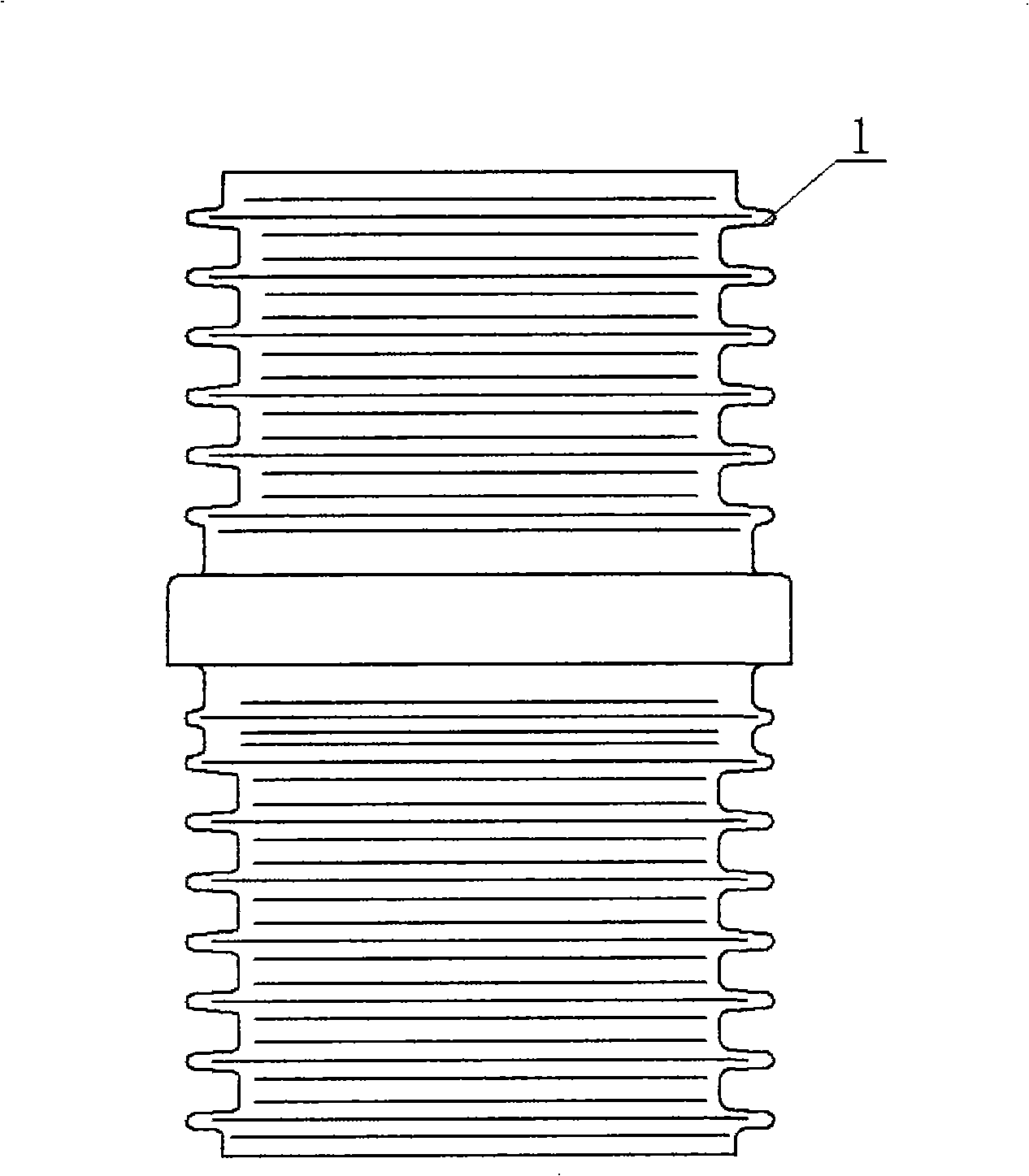

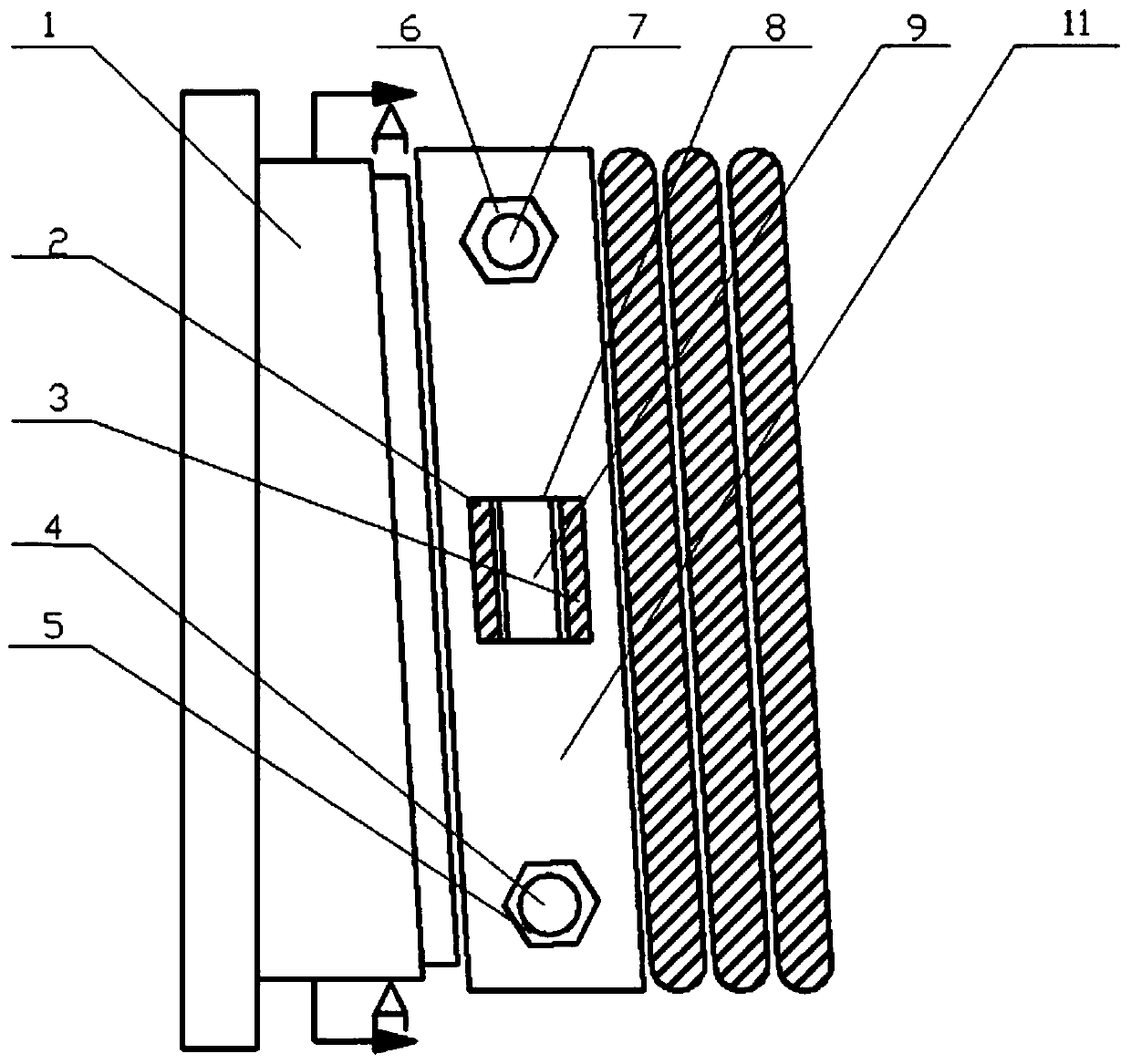

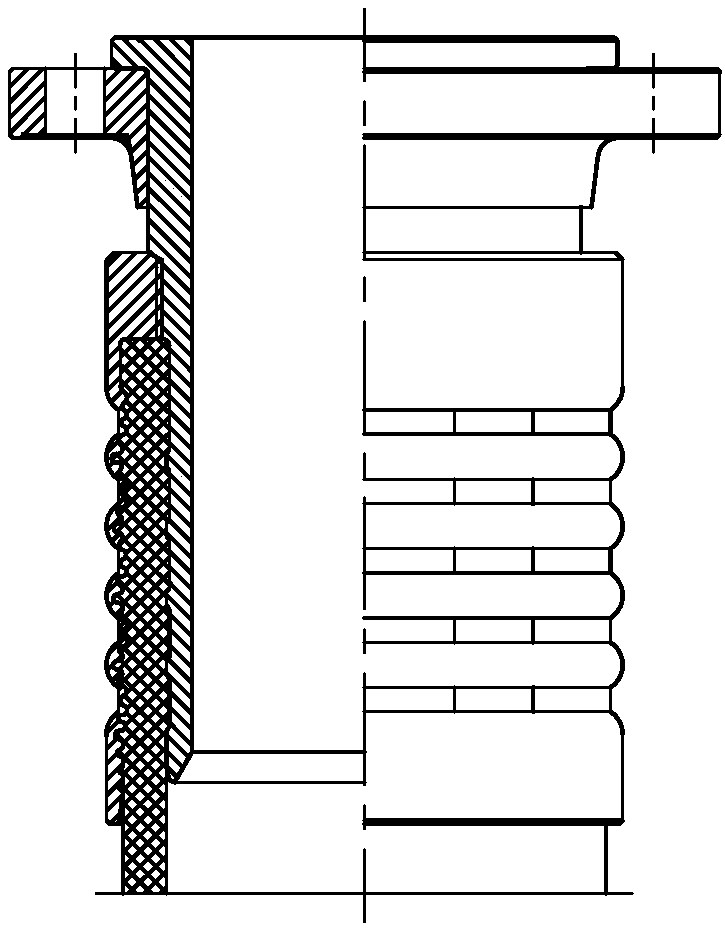

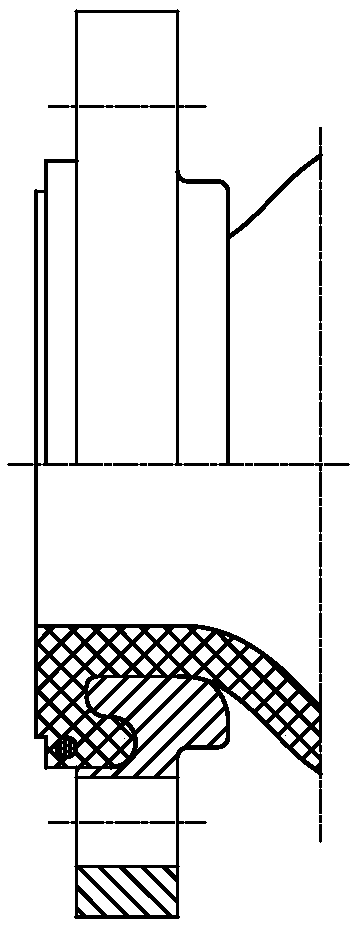

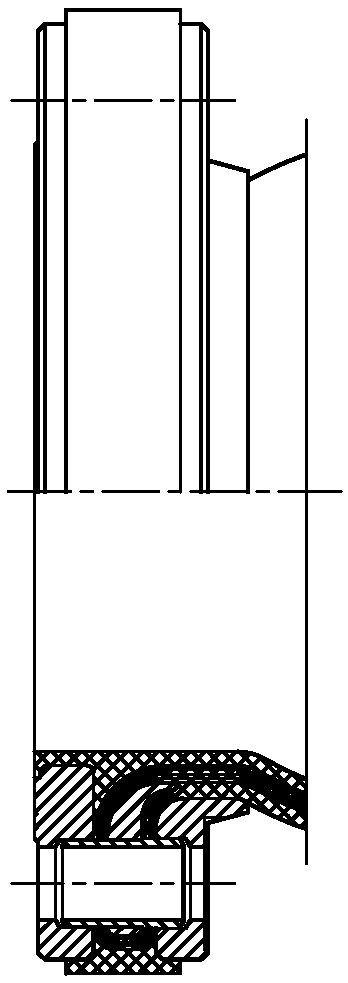

Large-diameter low-rigidity balancing flexible connecting tube for moveable flange and self-locking joint

The invention relates to a large-diameter low-rigidity balancing flexible connecting tube for a moveable flange and a self-locking joint. The connecting tube comprises a flexible tube body and buckling joints, wherein an inner glue layer, a skeleton layer and an outer glue layer are successively arranged in the flexible tube body from inner to outer; the buckling joints are symmetrically arranged at the two ends of the flexible tube body; each of the buckling joints comprises an outer pressing ring and an inner pressing ring; the outer pressing ring is arranged on the exterior of the inner glue layer at the end part of the flexible tube body in a sleeving manner; the front end of the skeleton layer is outward back turned and reversely wrapped on the front end face and the side wall of an annular plate; the inner glue layer, the skeleton layer, the outer glue layer, the outer pressing ring and the inner pressing ring are vulcanized and integrally formed. Through the symmetrical structures at the two ends of the tube body and the structure of the buckling joints, the technical problems of the traditional connecting tube of easiness in creeping, aging and losing efficacy, falling risk, complex joint structure, high dead weight, low flexibility, inferior vibration-reducing noise-attenuating effect, insufficient displacement compensation performance and easiness in cracking of welding joint are solved.

Owner:NAVAL UNIV OF ENG PLA +1

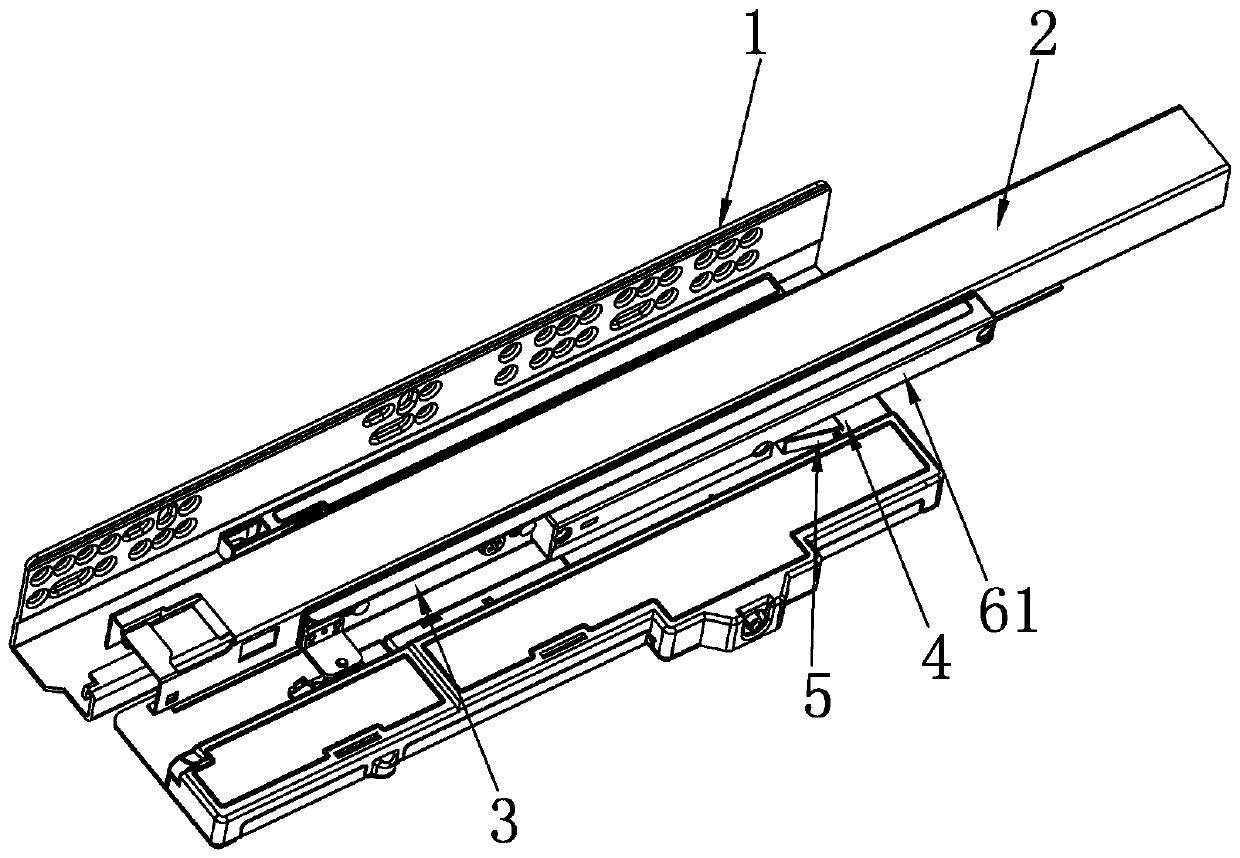

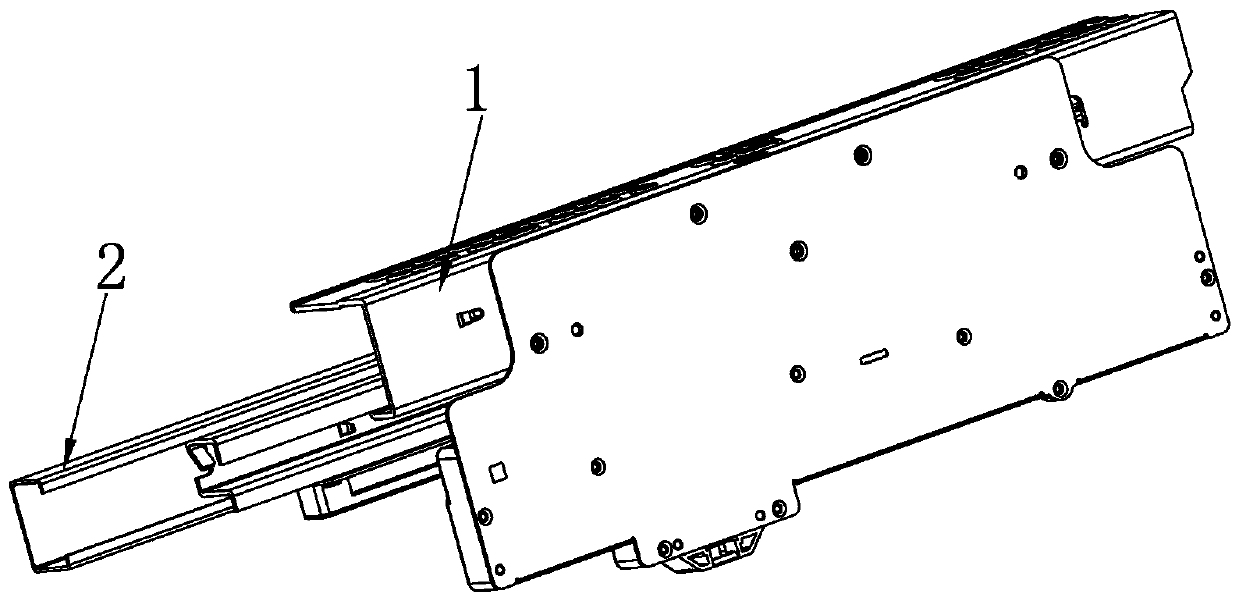

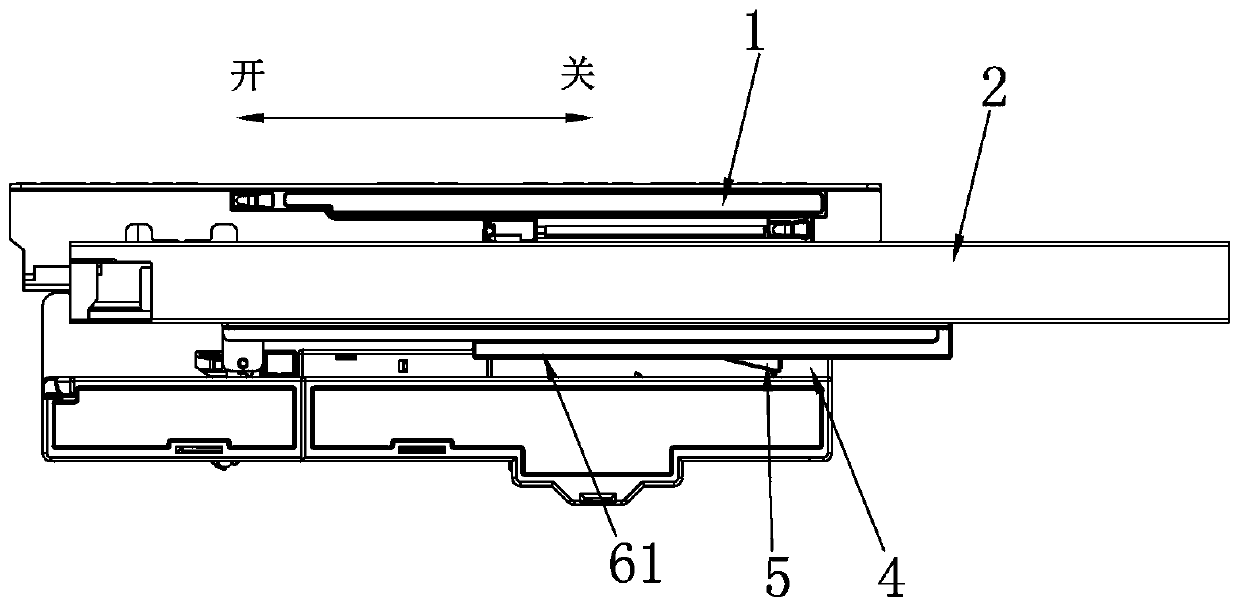

Drawer guide track pressing rebounder

A drawer guide track pressing rebounder comprises a base and a first protecting cover which are fastened to each other. A first hook is mounted on a base in a hinged manner; a first guide track is arranged in the first protecting cover, a first rebounding slider slides on the first guide track, a second hook is arranged at the end, which is in butt joint with the first hook, of the first rebounding slider, the first hook and the second hook can be hooked or separated from each other, a first tension spring is arranged between the first rebounding slider and the first protecting cover, the first tension spring always pulls the first rebounding slider towards the closing direction, and the inner end of the first rebounding slider is abutted to a rebounding hanging block. The drawer guide track pressing rebounder has the beneficial effects that by the structure, pressing rebounding starting of the guide track can be realized, and the using experience of a user is improved favorably.

Owner:陈明开

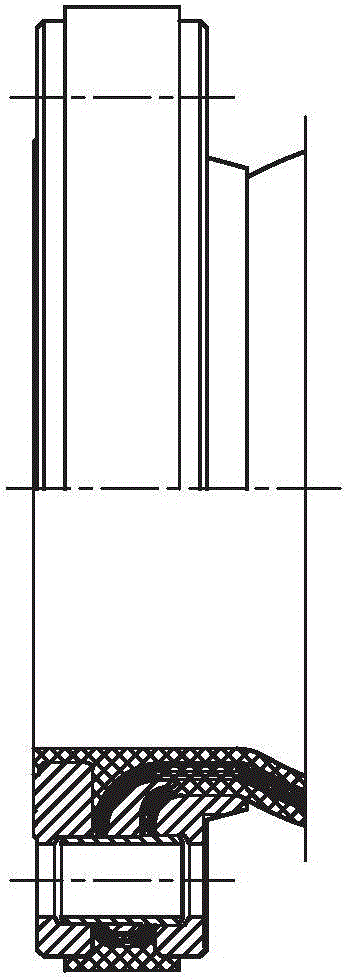

Axial buckling and pressing connector

The invention relates to an axial buckling and pressing connector. The axial buckling and pressing connector comprises an intra-pipe glue layer, a framework layer and an extra-pipe glue layer which are all of cylindrical structures and are sequentially connected in a sleeved manner from inside to outside to form a pipe body; the intra-pipe glue layer and the framework layer extend out of the pipe body from the same end, and the framework layer is made of flexible materials; the buckling and pressing connector further comprises an outer pressing ring and an inner pressing ring, the front end of the extending-out end of the intra-pipe glue layer is sleeved with the outer pressing ring, and the back section of the framework layer is sleeved with the inner pressing ring; and the outer pressing ring, the front section of the framework layer, the inner pressing ring and a piston flange are sequentially pressed in a butting manner from the extending-out end to the other end in the axial direction of the pipe body and are integrally molded through vulcanization. Compared with a flexible connecting pipe with the same length, a connecting structure adopting the connector and the pipe body is characterized in that the connector size is small, the flexibility section of the pipe body is long, the structure is simple, installation is flexible, and the connector and the pipe body are more firmly combined through vulcanization integrated molding. The technical problems that a traditional axial buckling and pressing connector is low in connecting strength, poor in pulling and dropping resistance and free of the self-locking function are solved.

Owner:NAVAL UNIV OF ENG PLA +1

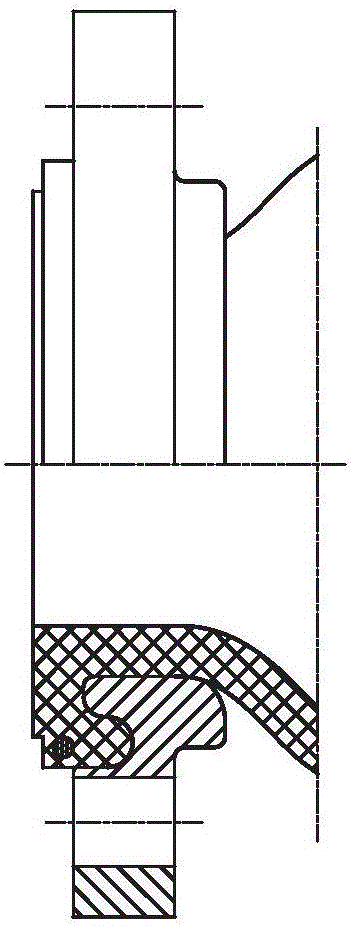

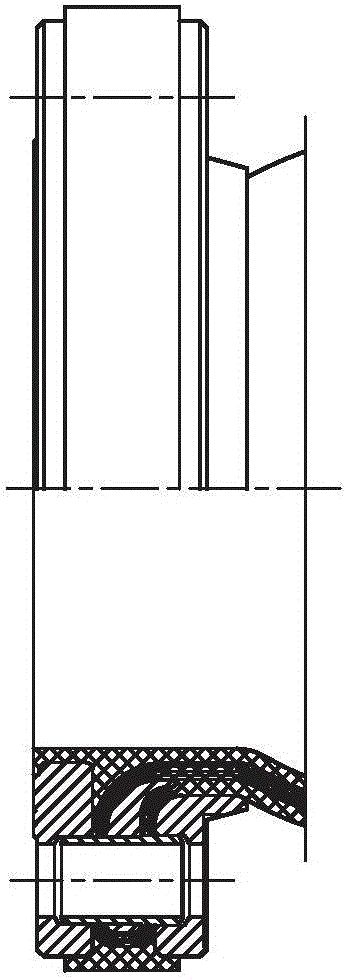

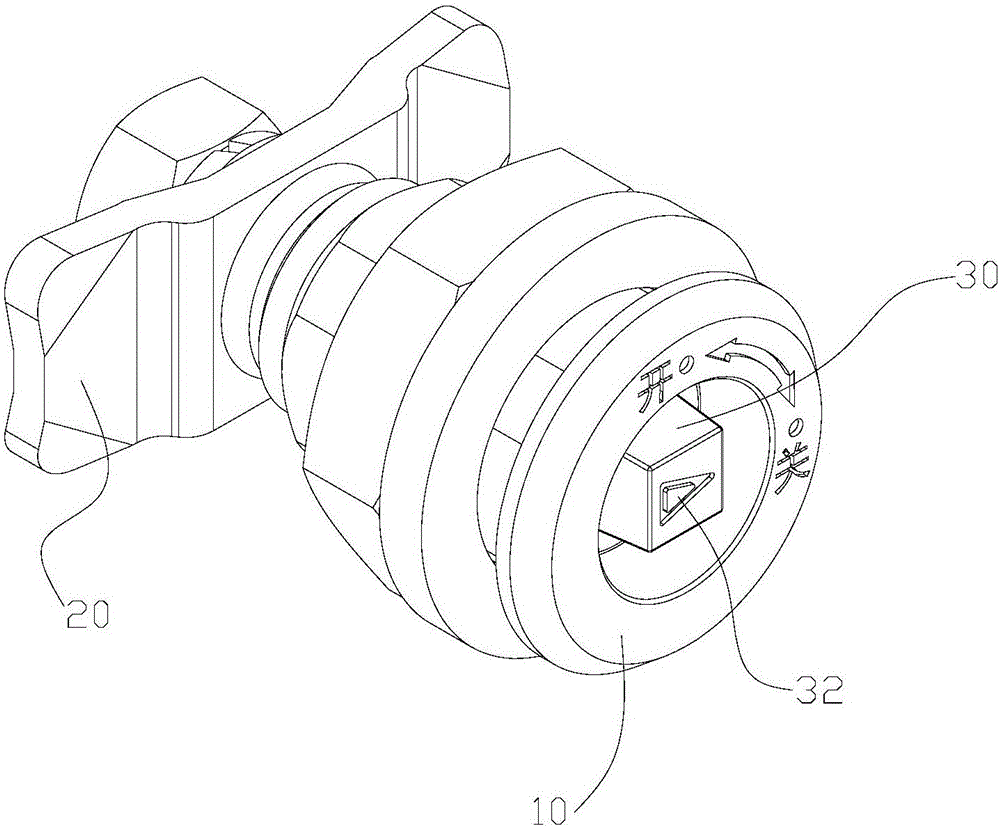

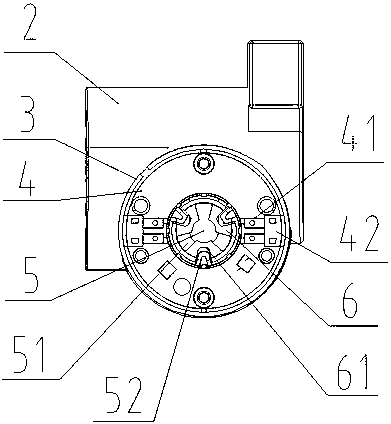

Cam lock and rail vehicle with cam lock

InactiveCN105041063AImprove carrying capacityAdd self-locking functionBuilding locksEngineeringMechanical engineering

The invention discloses a cam lock. The cam lock comprises a lock body, a bolt and a lock cylinder. The lock cylinder comprises an outer lock cylinder body and an inner lock cylinder body. The head of the inner lock cylinder body is located in a through hole of the lock body and comprises a lap joint face in lap joint with the inner end face of the lock body. The tail of the inner lock cylinder body extends out of the lock body. The bolt is fixedly arranged at the tail of the inner lock cylinder body in a sleeving mode. The outer lock cylinder body is arranged in the through hole of the lock body, can slide towards the inner lock cylinder body and can be matched with the inner lock cylinder body so as to rotate jointly. A reset spring is arranged between the outer lock cylinder body and the inner lock cylinder body. The cam lock is large in bearing capacity and can meet the requirements of installing skirting boards with different bearing capacities under different working conditions; in addition, the self-locking function is simple and reliable, and safety is high. The invention further discloses a rail vehicle with the cam lock.

Owner:CRRC QINGDAO SIFANG CO LTD

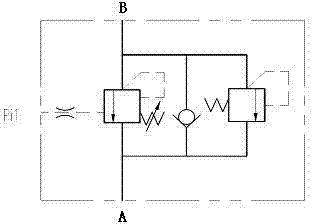

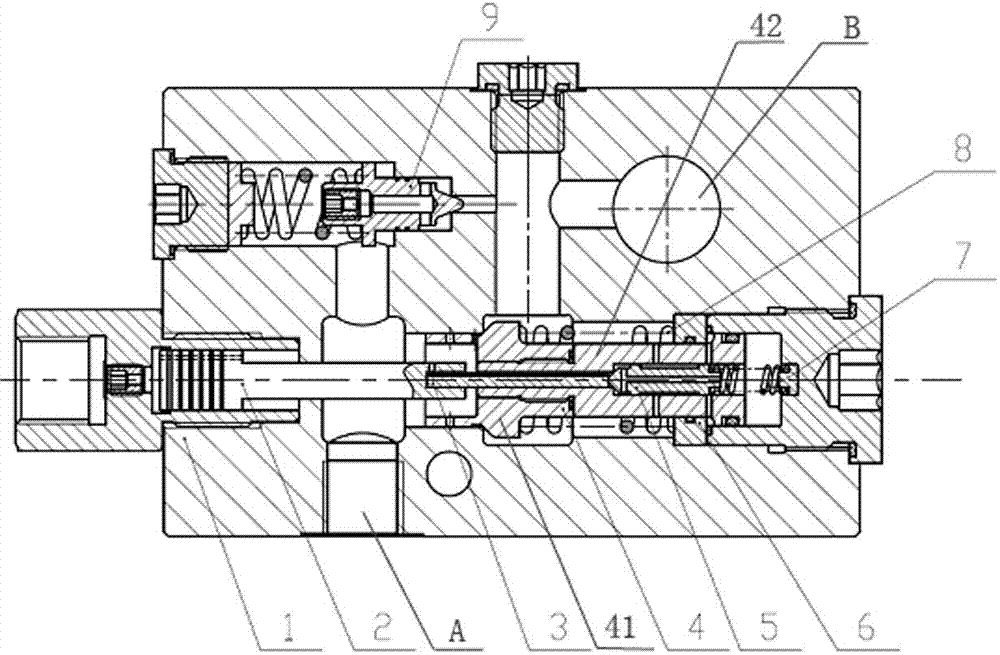

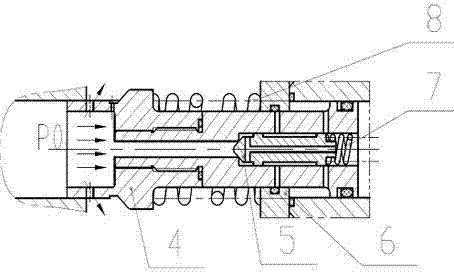

Mechanical balance valve with foldable cantilever crane

InactiveCN104500475AAvoid attenuationAdd self-locking functionServomotor componentsEngineeringControl valves

The invention discloses a mechanical balance valve with a foldable cantilever crane. The mechanical balance valve comprises a first oil port, a second oil port, a valve body, a control valve core, a balance valve core, a high-pressure cavity and low-pressure cavity isolating block and an overflow valve core, wherein the valve body is provided with a pilot control oil cavity, a load cavity and a pilot valve spring cavity; the first oil port is communicated with the pilot control oil cavity; the second oil port is communicated with the load cavity; the control valve core is arranged in the pilot control oil cavity; the balance valve core is arranged in the load cavity; the pilot control oil cavity is isolated from the load cavity; the balance valve core comprises a valve head and a valve rod; the valve head is arranged at one end, which faces the control valve core, of the valve rod; the valve rod passes through a center hole of the high-pressure cavity and low-pressure cavity isolating block; a spring is arranged between the valve head and the high-pressure cavity and low-pressure cavity isolating block; a through hole is formed in the center of the valve rod; a small pilot valve core is arranged in the hole; the small pilot valve core is provided with a groove which is communicated with the load cavity and a high-pressure unloading cavity. The mechanical balance valve has the advantages of high dynamic stability, low control pressure and high locking property.

Owner:XIANGTAN UNIV

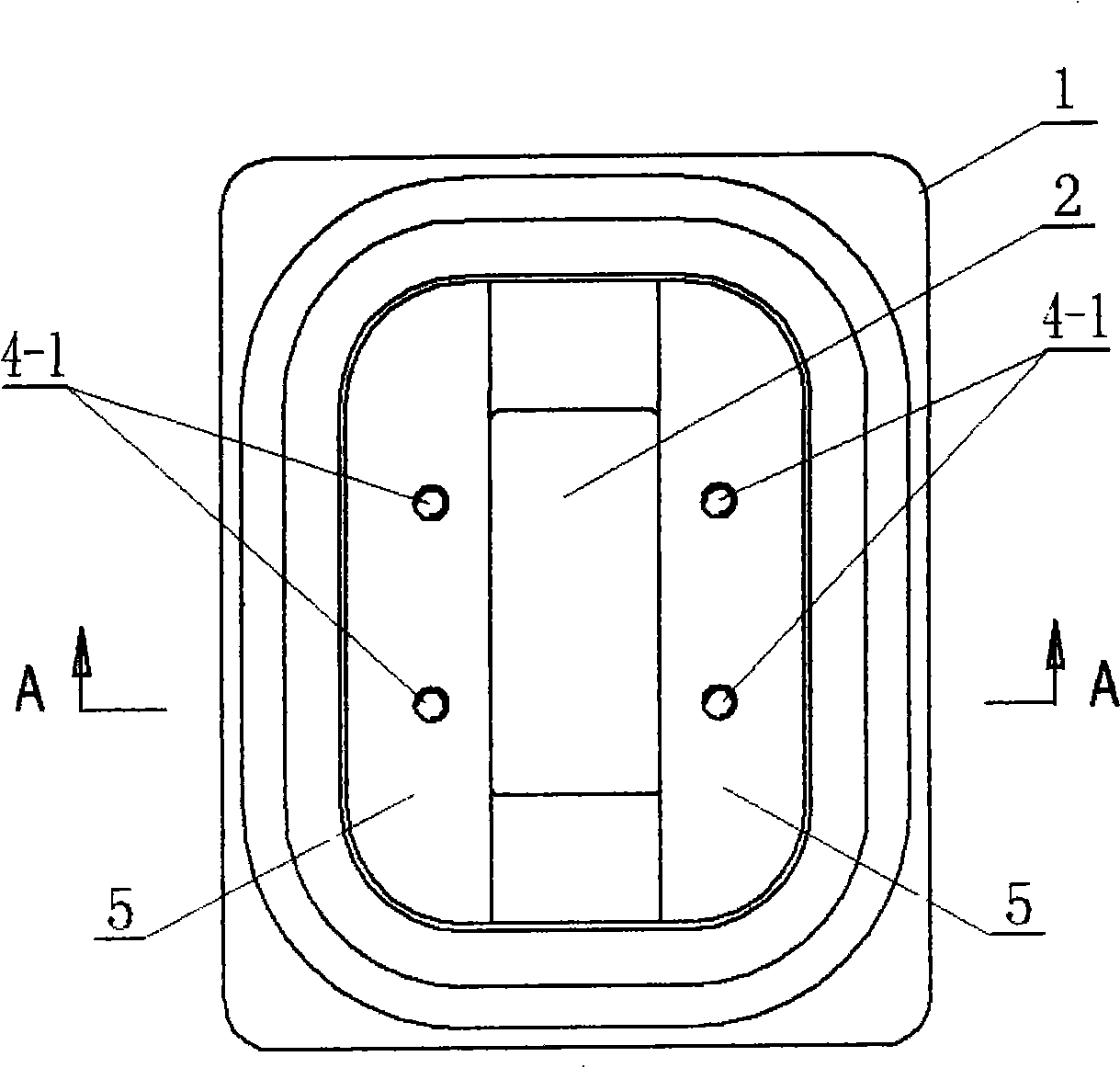

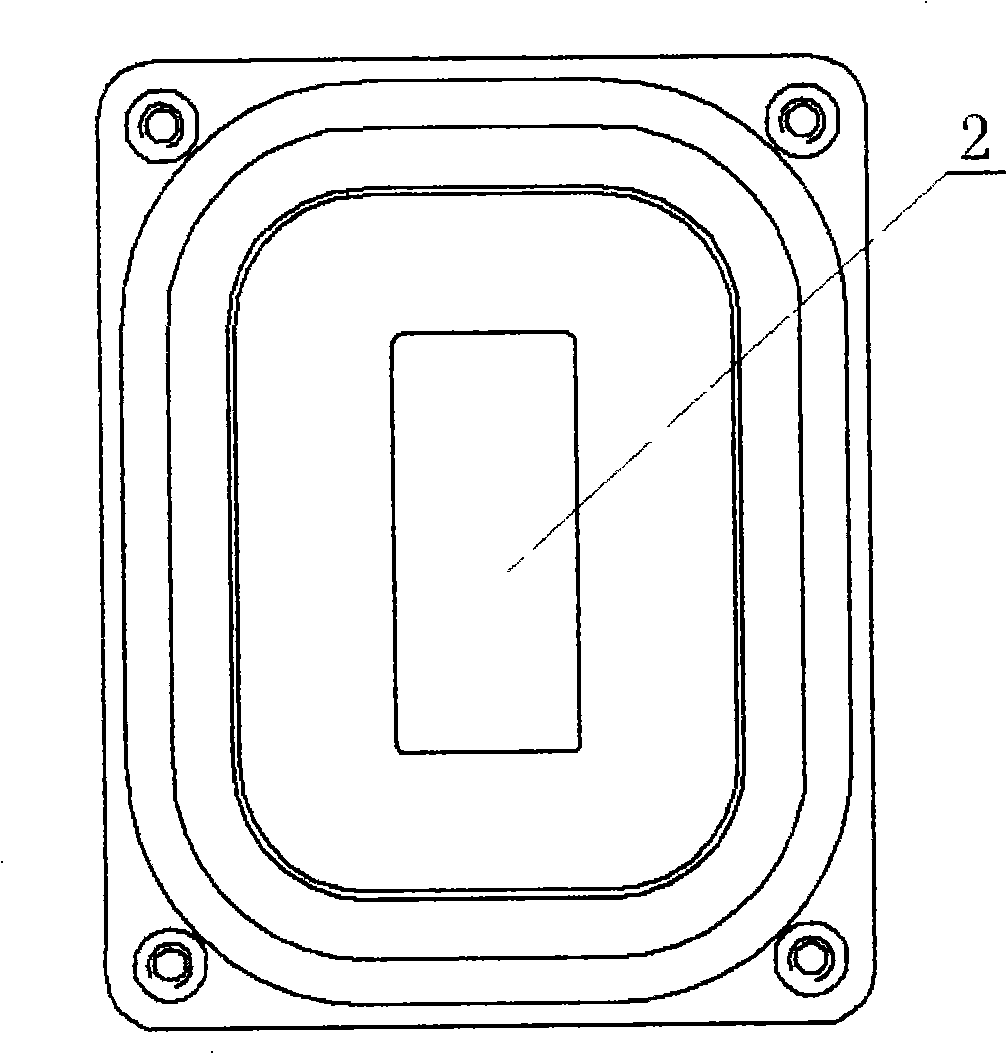

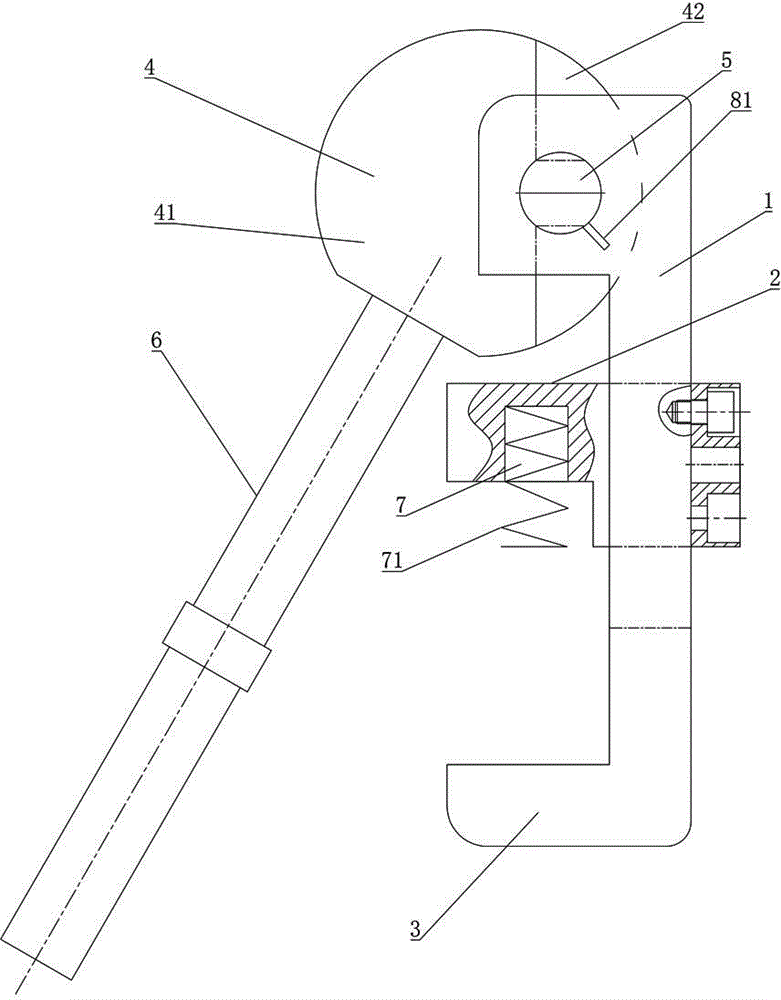

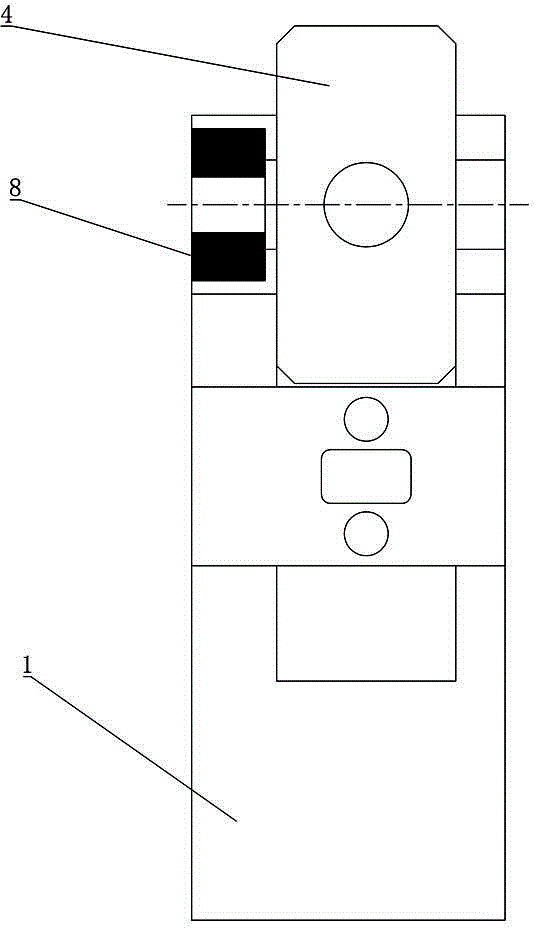

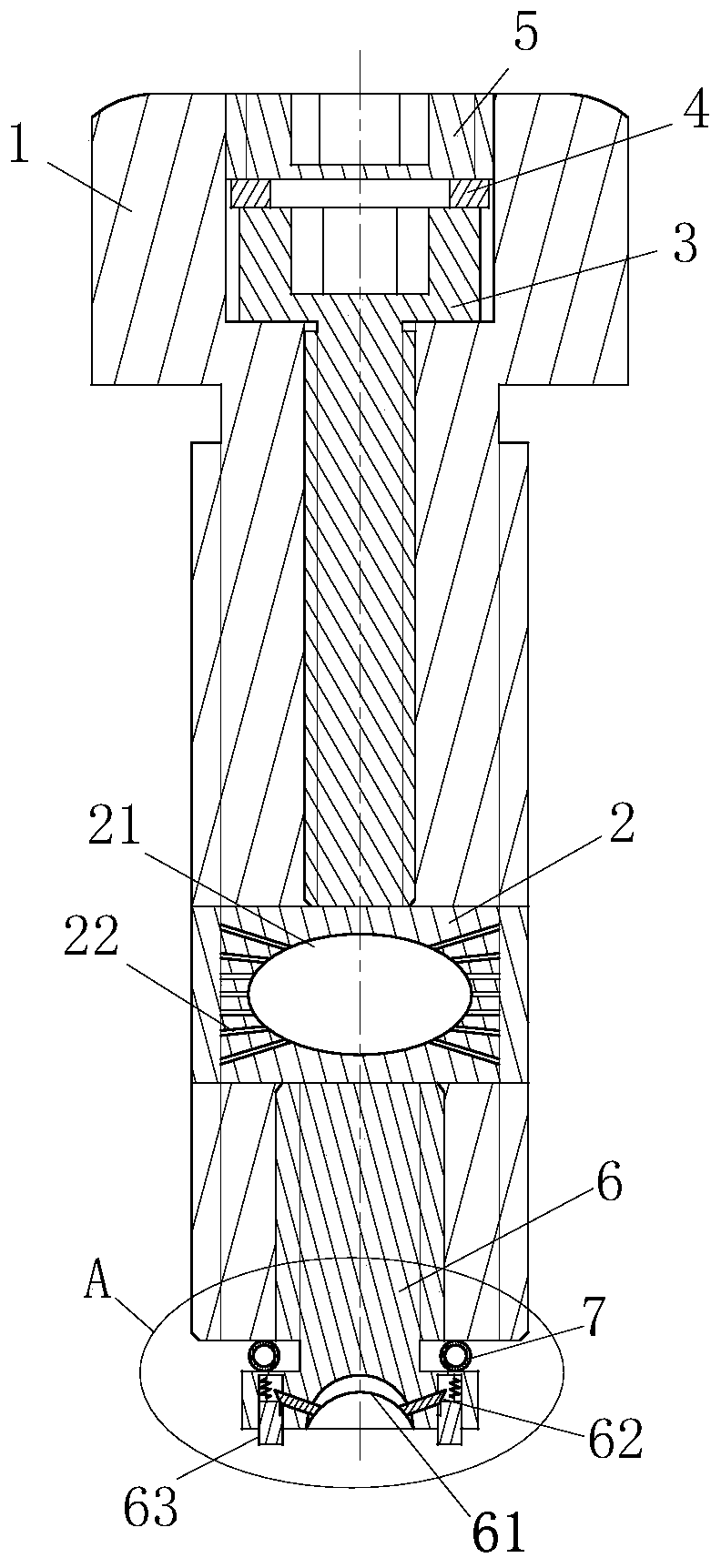

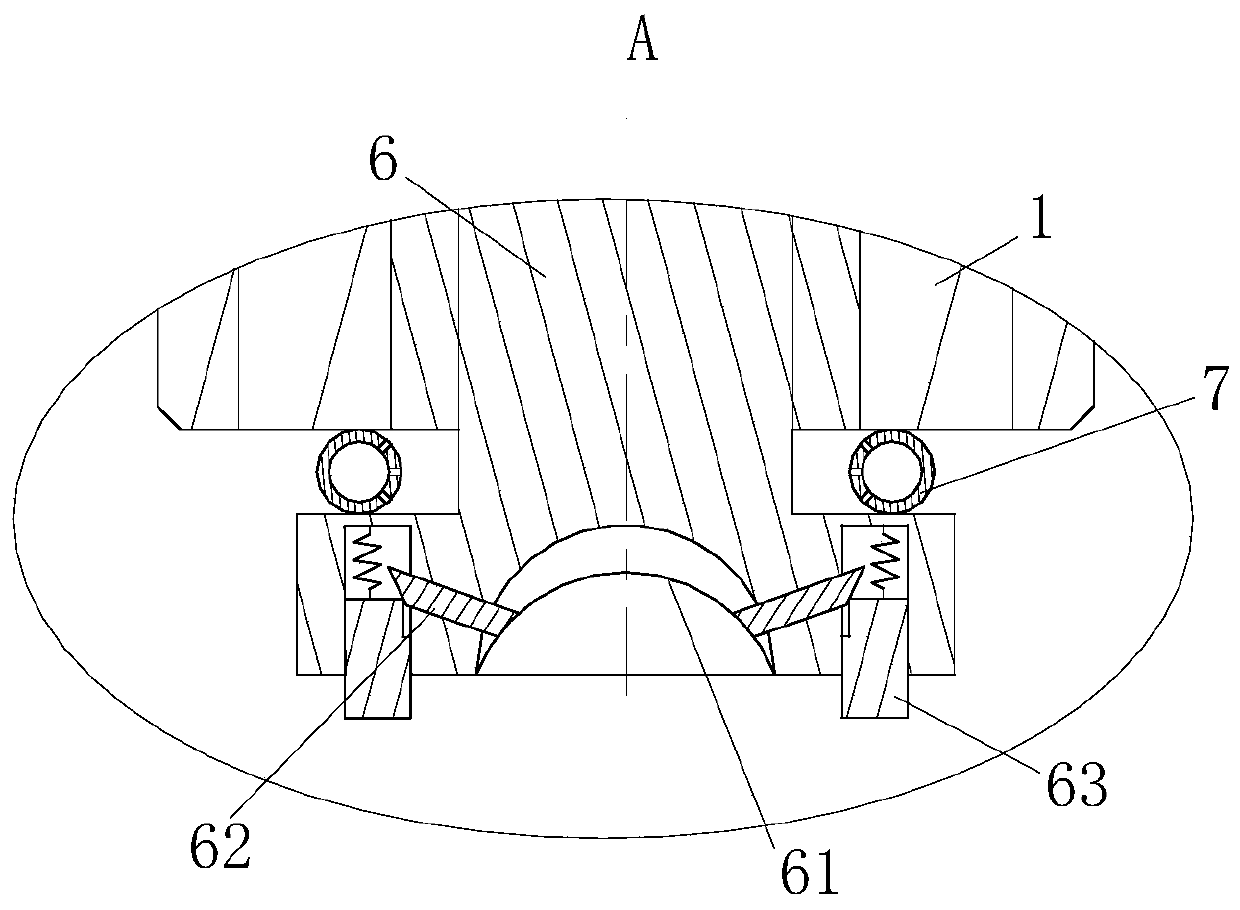

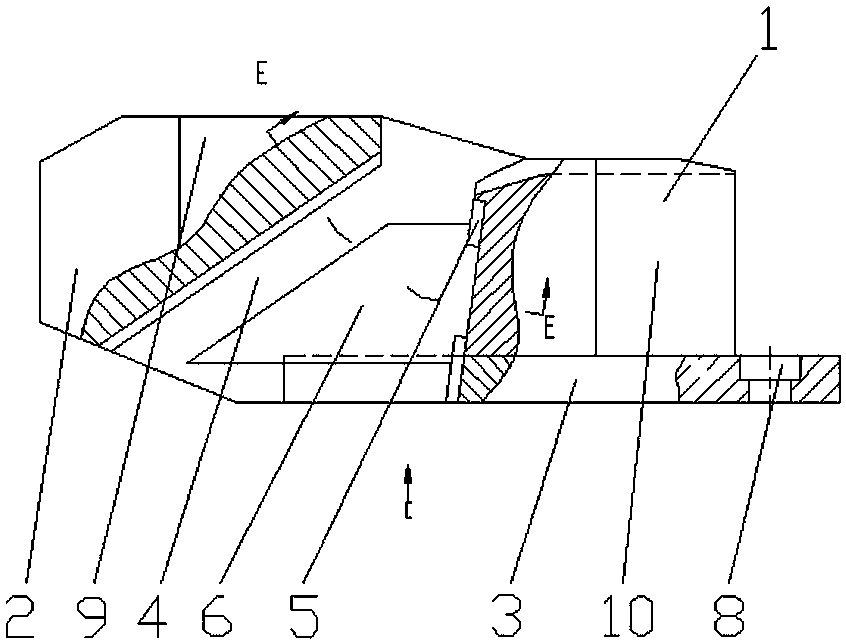

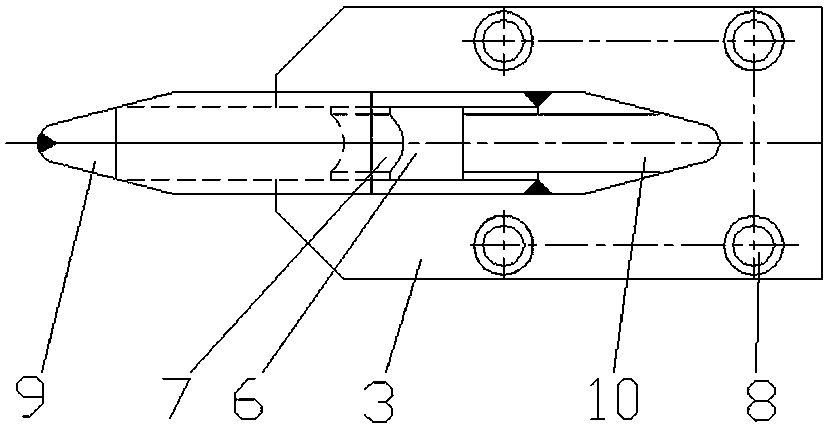

High pressure self-locking type wall bushing

The invention discloses a high pressure self-locking wall bushing comprising a wall bushing casing (1), a bus perforation (2), a bus (3), a screw (4), inclined structures (5) integrated with the casing (1) respectively arranged on the left and right sides of the bus perforation (2) in the casing (1), pressing members (6) having the same inclined plane with the left and right inclined structures (5) arranged on the inclined structures (5), screw perforations (4-1) and nut copper inserts (7) arranged in the two inclined structures (5) combining with the pressing members (6) through the screw (4) and fixed on the planes of the two inclined structures (5). The wall bushing of the invention increases self-locking function, which can conveniently lock the bus firmly, solve the technical problem of dynamic stability better, ensure that the switchgear under 40.5kV operates more safely and reliably and suit for the occasions on which high voltage live bus is needed cross such as between the cases on the high voltage switchgear, the incoming lines and outgoing lines of the high voltage switchgear and each small isolated cabinets in the cases, especially for the switchgear electrical equipment towards miniaturization trend.

Owner:GUANGXI YINHE DECOM ELECTRIC

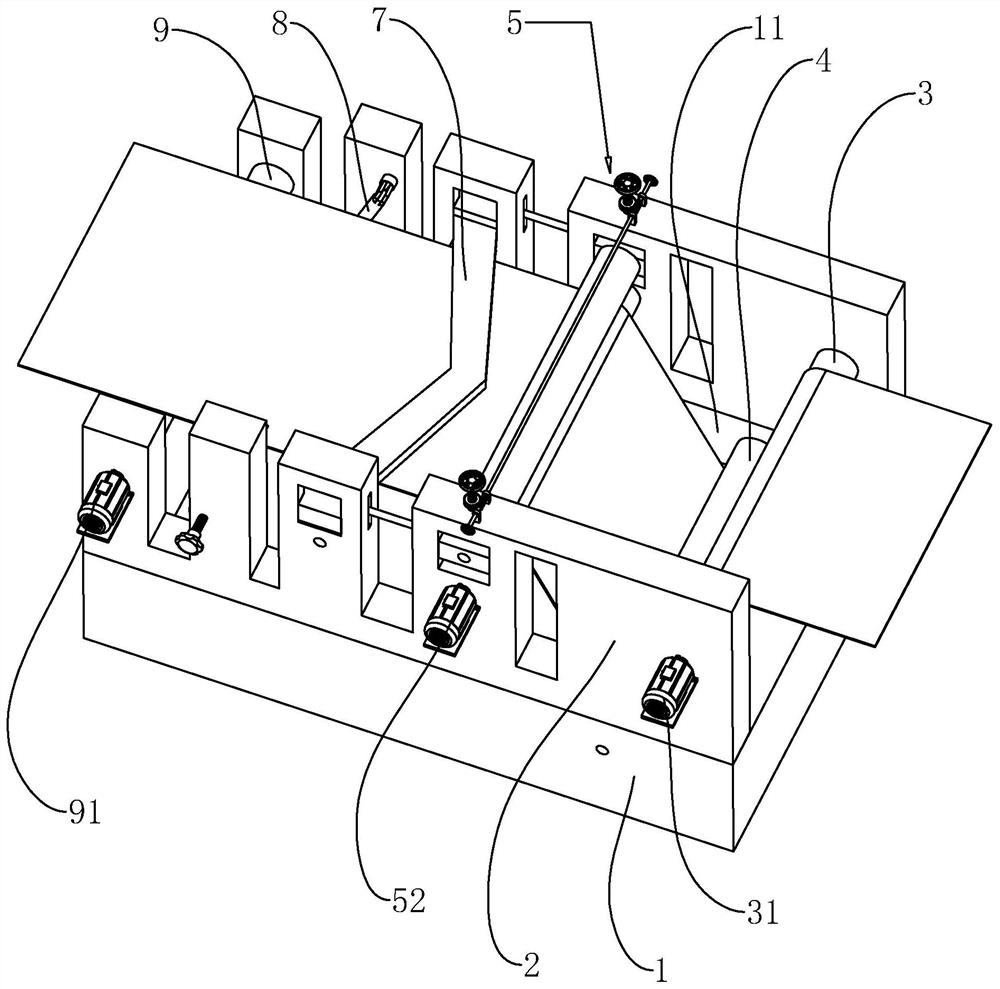

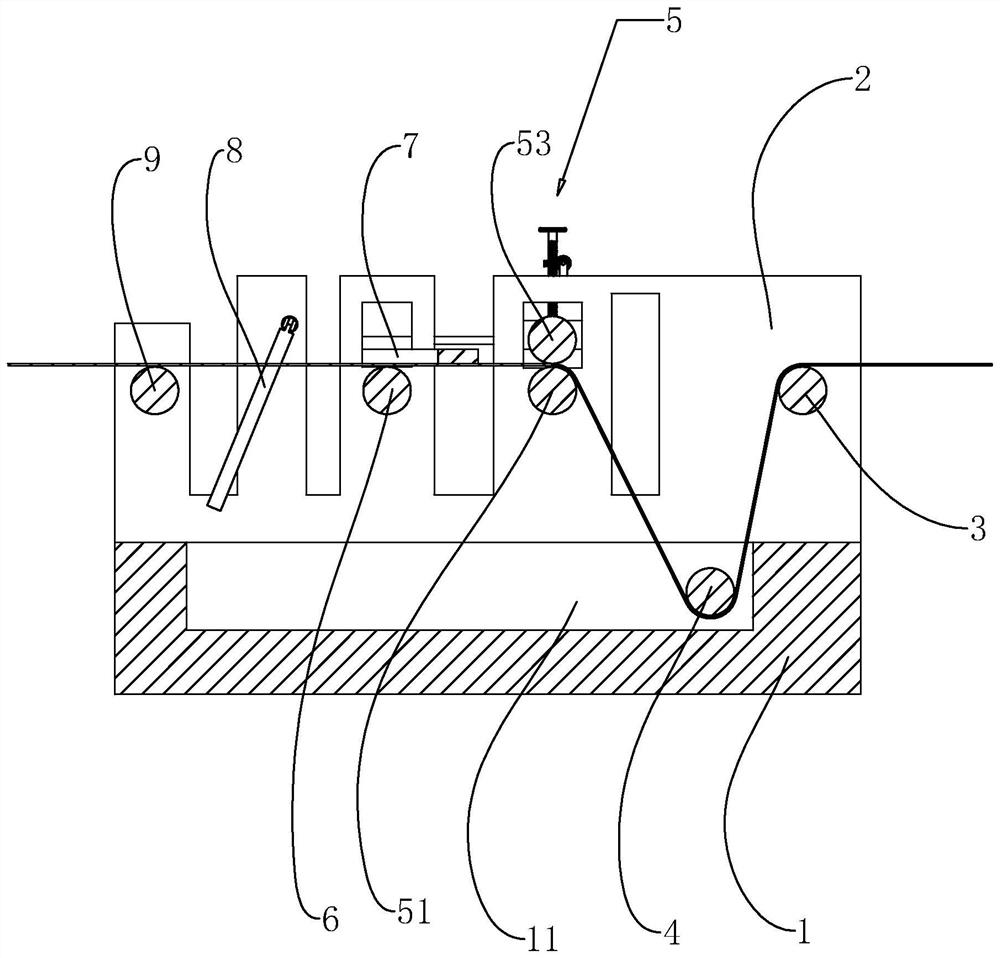

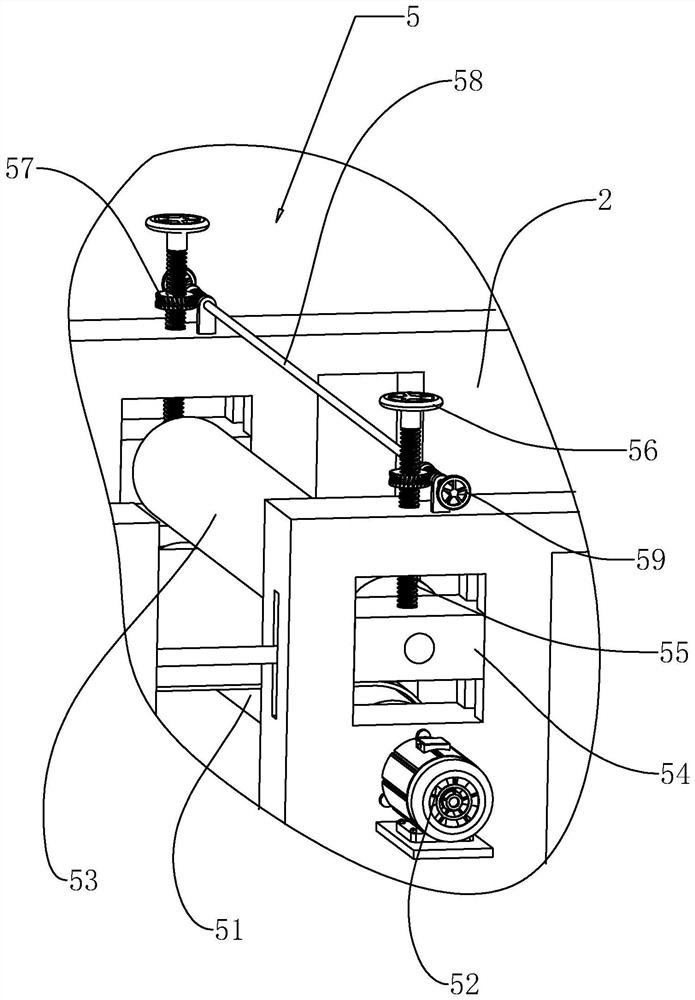

SBS modified asphalt waterproof coiled material production line

ActiveCN112108320APrevent fallingReduce wasteLiquid surface applicatorsCoatingsGlass fiberProduction line

The invention relates to an SBS modified asphalt waterproof coiled material production line. The SBS modified asphalt waterproof coiled material production line comprises a machine body, a machine frame is fixedly arranged on the machine body, an asphalt storage tank is formed in the top end of the machine body, a feeding transmission roller is rotationally connected to one end of the machine frame, and a guide roller arranged in the asphalt storage tank is rotationally connected into the machine body. A discharging transmission roller is rotationally connected with the end, away from the feeding transmission roller, of the machine frame, and the feeding transmission roller, the guide roller and the discharging transmission roller are parallel to one another. A press-fit mechanism is arranged on the machine body and arranged between the discharging transmission roller and the guide roller, two side scraping rods arranged between the press-fit mechanism and the discharging transmissionroller are arranged on the machine frame, the side scraping rods are correspondingly arranged on the two sides of a glass fiber layer and abut against the two sides of the glass fiber layer, and the ends, away from the machine frame, of the side scraping rods are arranged on the asphalt storage tank. The side scraping rods scrape off redundant asphalt on the two sides of the glass fiber layer, theamount of asphalt falling off from the two sides of the glass fiber layer in the subsequent process is reduced, and the effect of reducing asphalt waste is achieved.

Owner:上海建材集团防水材料有限公司

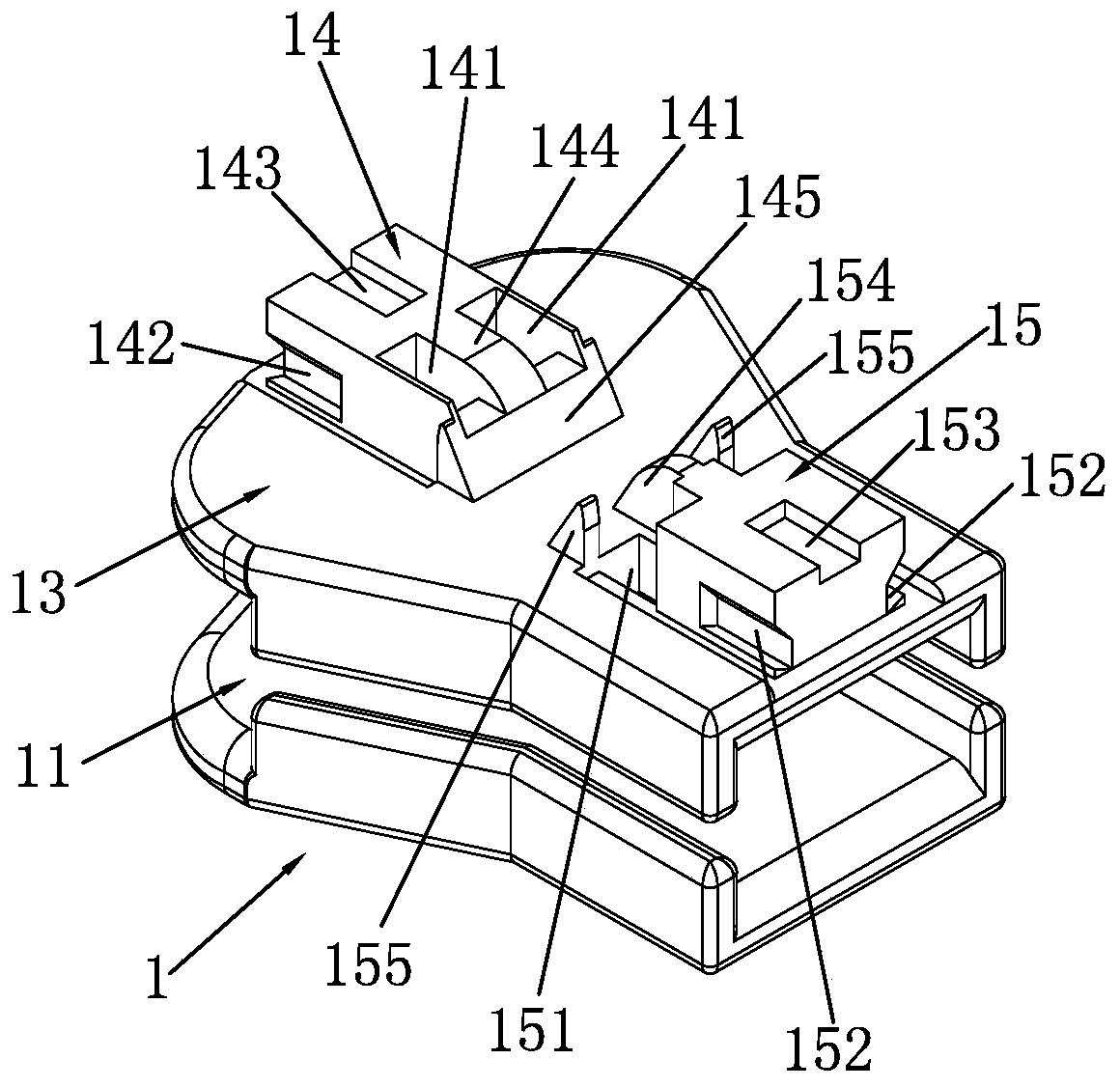

Driver box body structure

PendingCN108616186AHigh matching precisionHigh accuracy consistencySupports/enclosures/casingsEngineeringMechanical engineering

The invention discloses a driver box body structure. The driver box body structure comprises a driver upper box body, a driver lower box body, a motor front end cover and a motor brush rack plate, wherein the motor front end cover is arranged on the driver lower box body, the motor brush rack is arranged on the motor front end cover, a screw hole is formed in a side surface, a brush handle is arranged on the motor brush rack plate, a through hole is formed in the center, openings are formed in a front end and a rear end of the brush handle and communicate with each other, a limitation step isarranged in the through hole, a boss is arranged on the limitation step, and the driver lower box body, the motor front end cover, the motor brush rack plate and the brush handle are integratedly formed. By the driver box body structure, the matching accuracy of the driver box body and the product consistency are improved, the assembly process is reduced, and the cost is reduced; the openings areformed in the two ends of the brush handle, a rotor is pressed during assembly, a carbon brush is arranged, and the carbon brush is prevented from being damaged; a rotor bearing is reinforced by the formed screw hold matched with a screw, and the bearing is prevented from axially moving; and the automatic locking function of a driver is improved by a damping piece, and the problems that a large-range driver having the automatic locking function is high in cost and is easy to damage are solved.

Owner:DEWERTOKIN TECHNOLOGY GROUP CO LTD

Self-locking slider with double horse hooks

ActiveCN107183846BAdd self-locking functionNot easy to damageSlide fastenersClassical mechanicsEngineering

The invention provides a self-locking puller with double horse hooks. The self-locking puller comprises a puller body, a pulling sheet, a cap, an elastic sheet, and two horse hooks, the puller body is constituted by making a lower wing plate, a guide pillar and an upper wing plate connected, a front installation part and a rear installation part are arranged at the top surface of the upper wing plate, two first installation holes are formed in the front installation part, and two second installation holes are formed in the rear installation part; first connecting clamping grooves are formed in both the left side wall and the right side wall of the front mounting part, and second connecting clamping grooves are formed in both the left side wall and the right side wall of the rear mounting part; a first positioning groove is formed in the top of the front installation part, and a second positioning groove is formed in the top of the rear installation part; an opening groove is formed in the middle of the elastic sheet, and the elastic sheet is separated into a left elastic sheet and a right elastic sheet, and the left elastic sheet and the right elastic sheet are symmetrically arranged; loading lugs are arranged at the top end of the inside of the cap. In the elastic sheet of the self-locking puller, two mutually independent elastic parts are arranged to correspond to the two horse hooks, when the left elastic sheet and the right elastic sheet apply acting force to the corresponding horse hooks to achieve self-locking of the puller, the left elastic sheet and the right elastic sheet are not interfered mutually, and thus the self-locking function of the puller is sharply promoted.

Owner:FUJIAN SBS ZIPPER SCI & TECH CO LTD

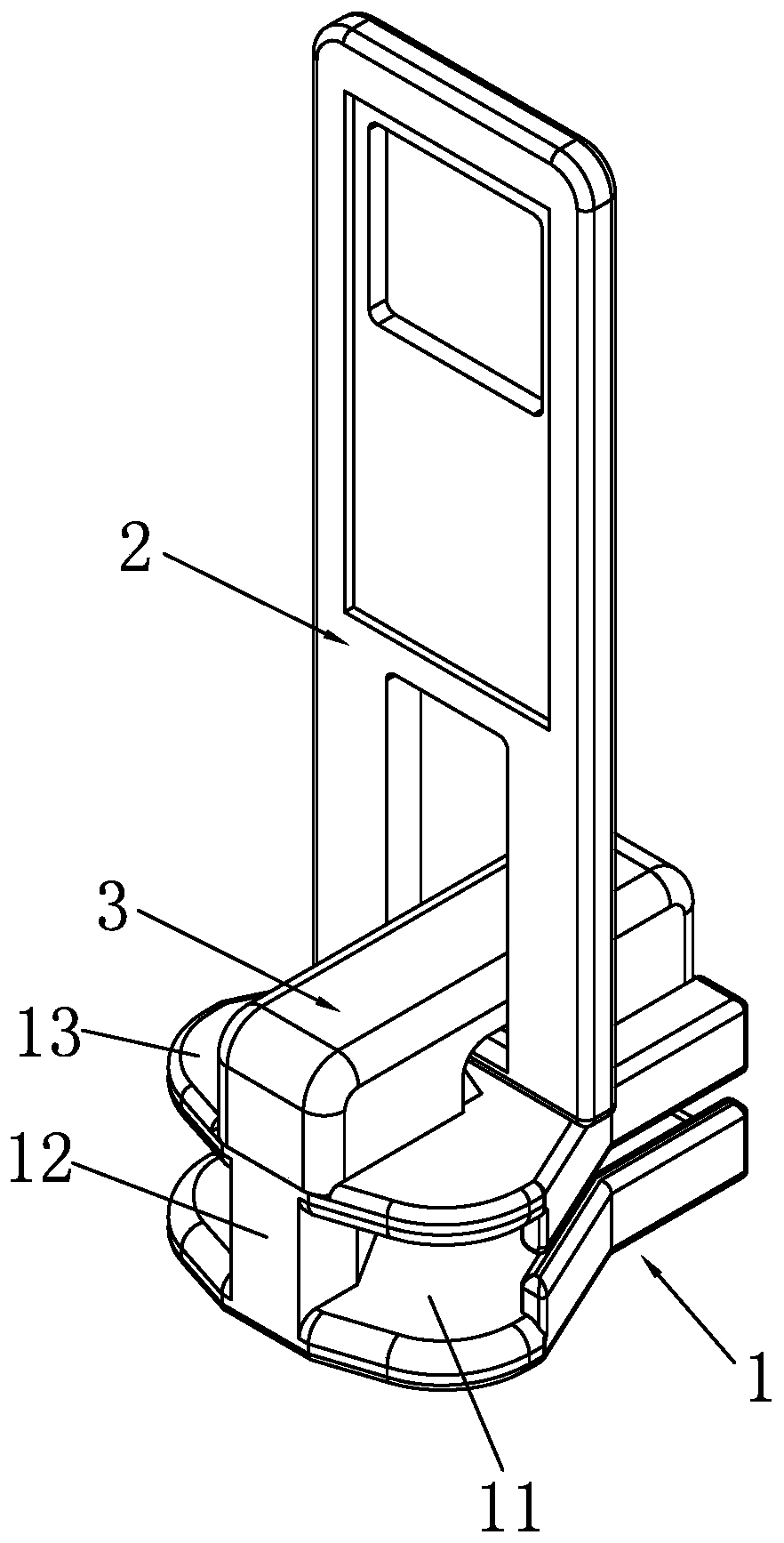

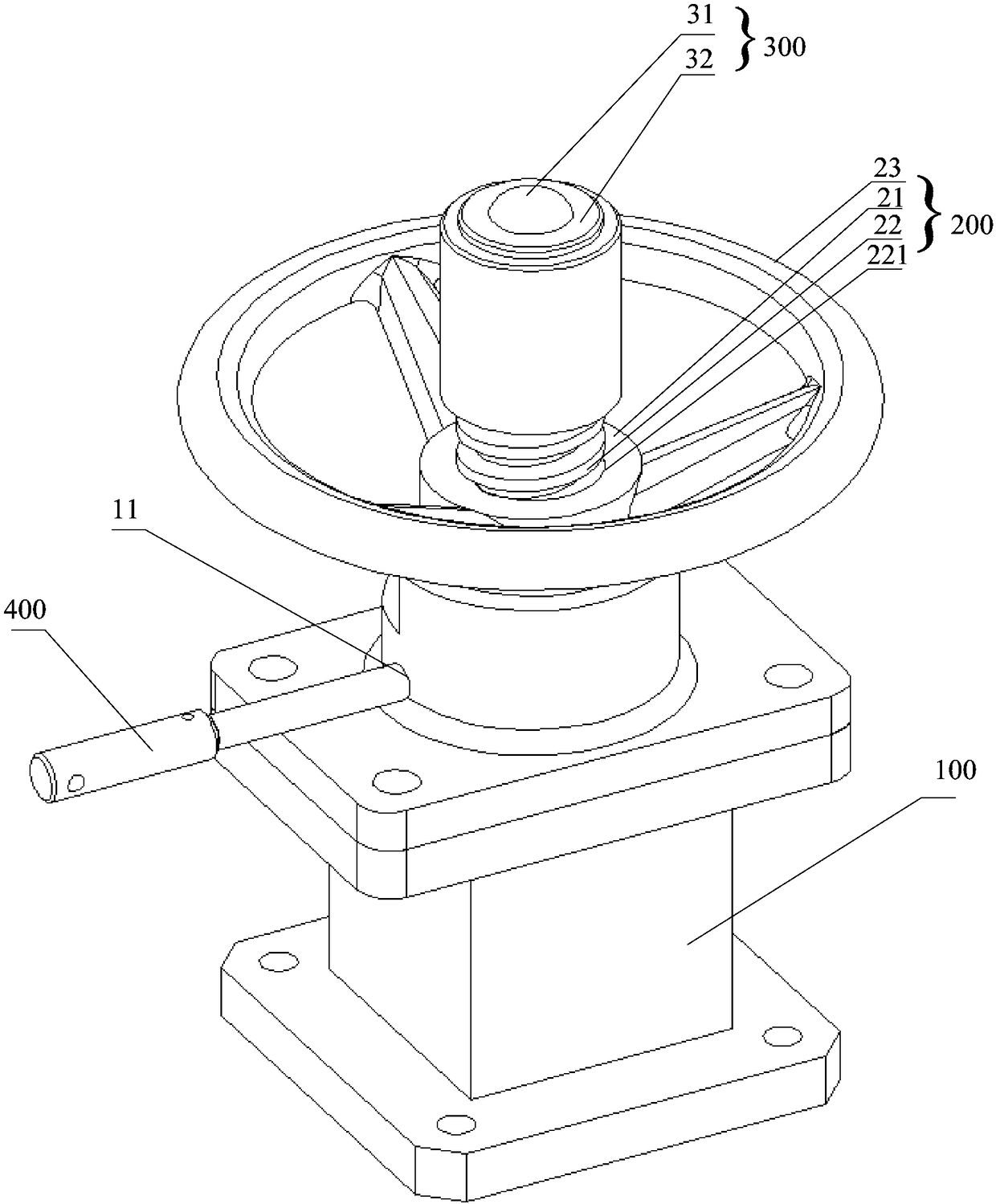

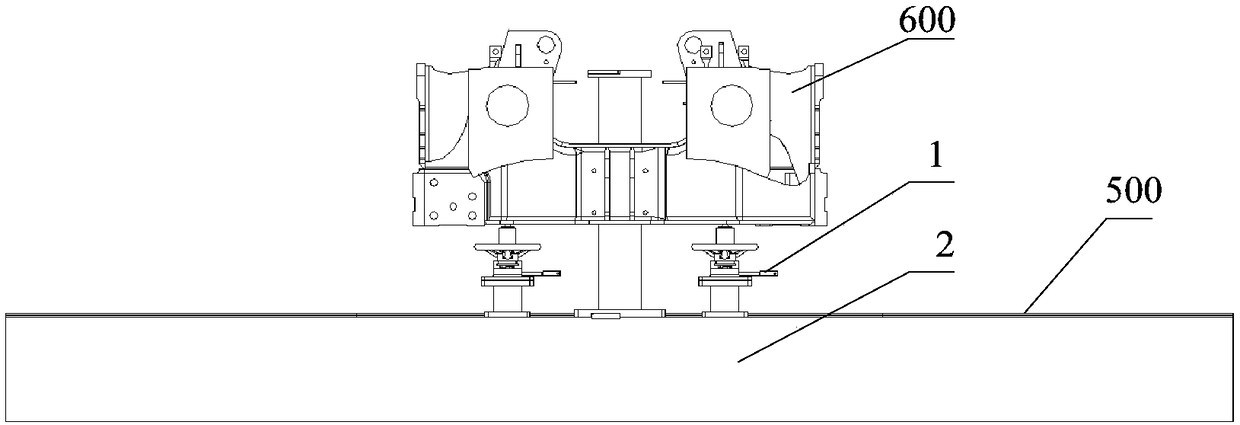

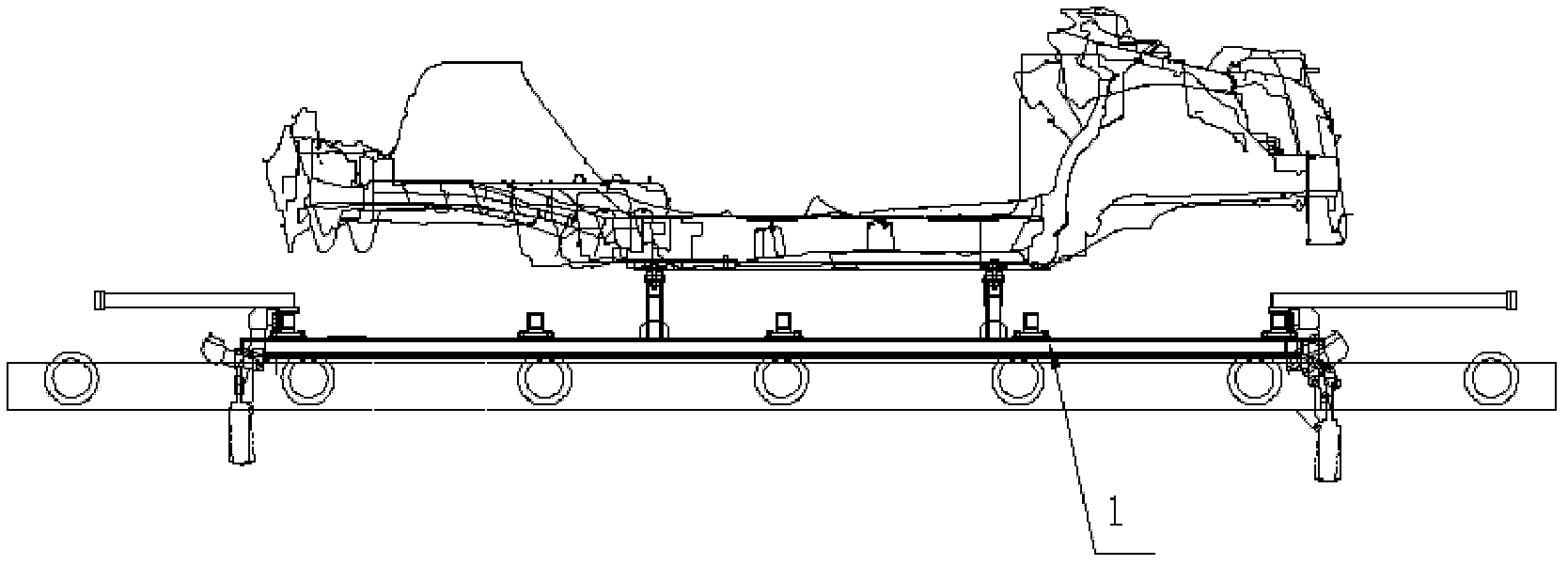

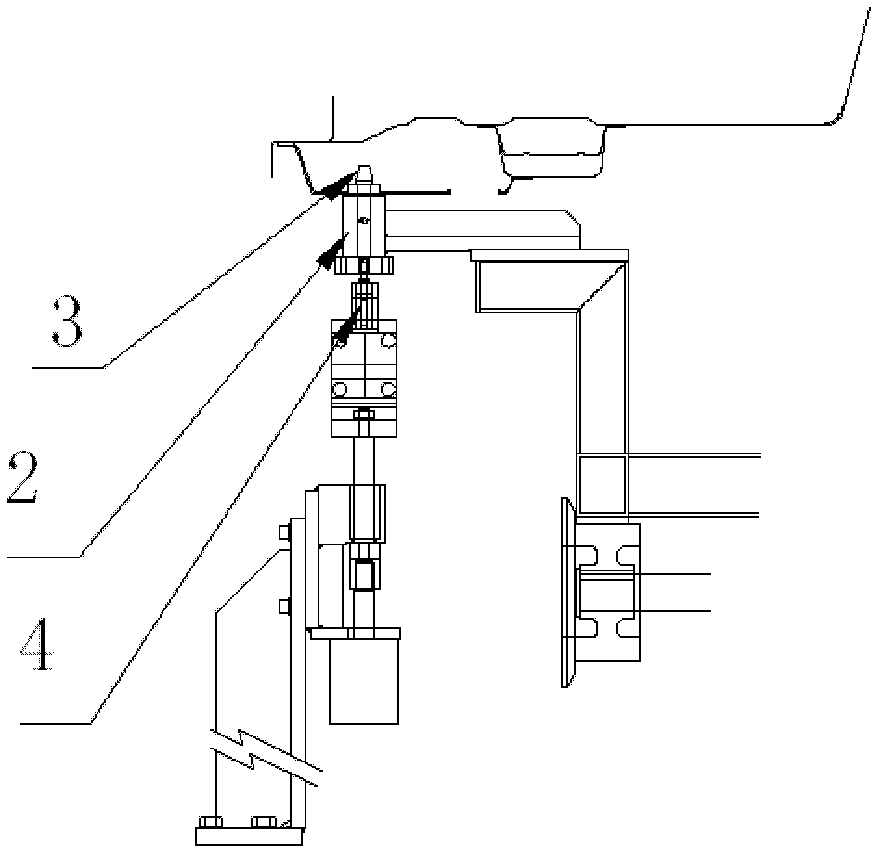

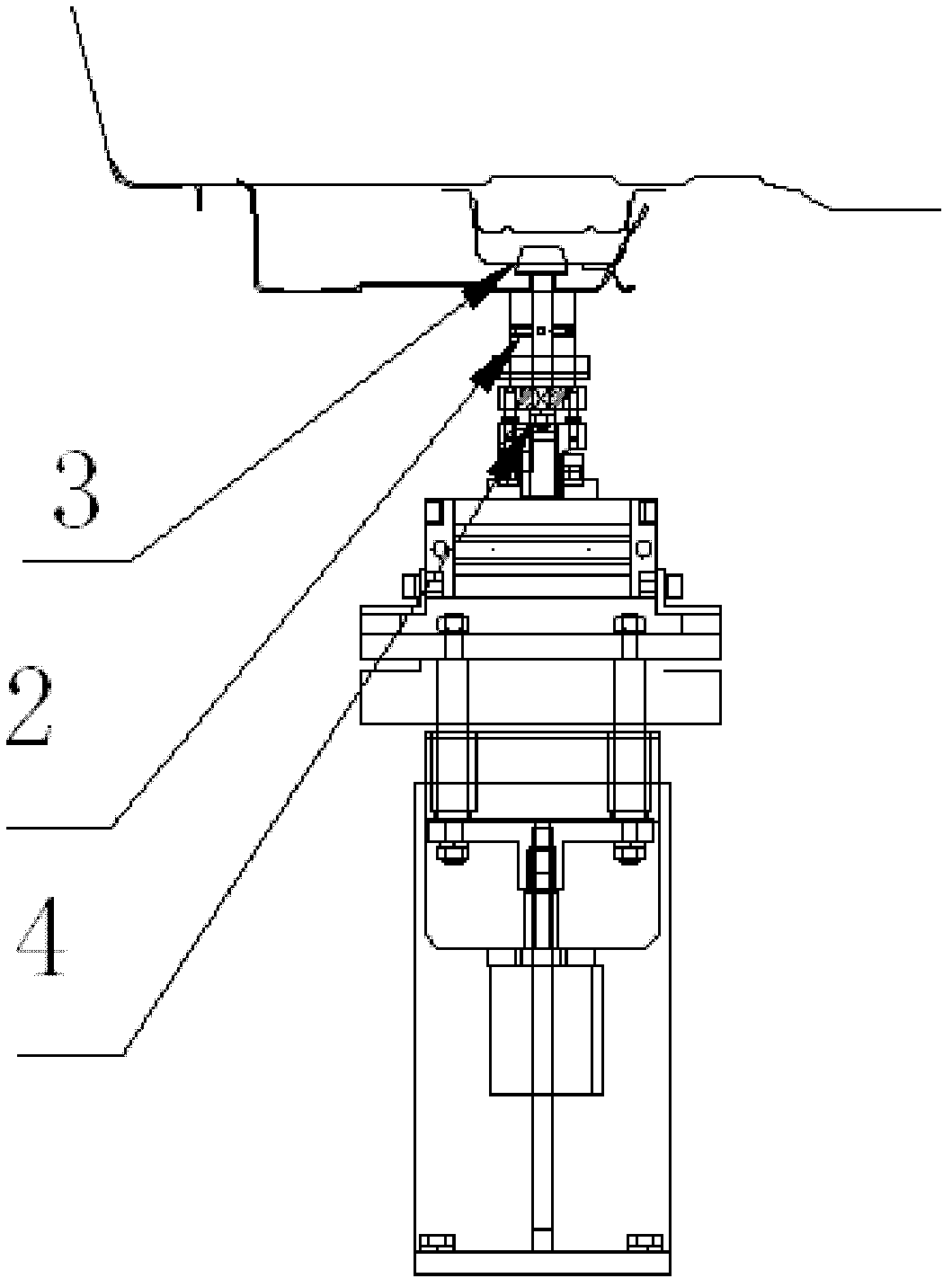

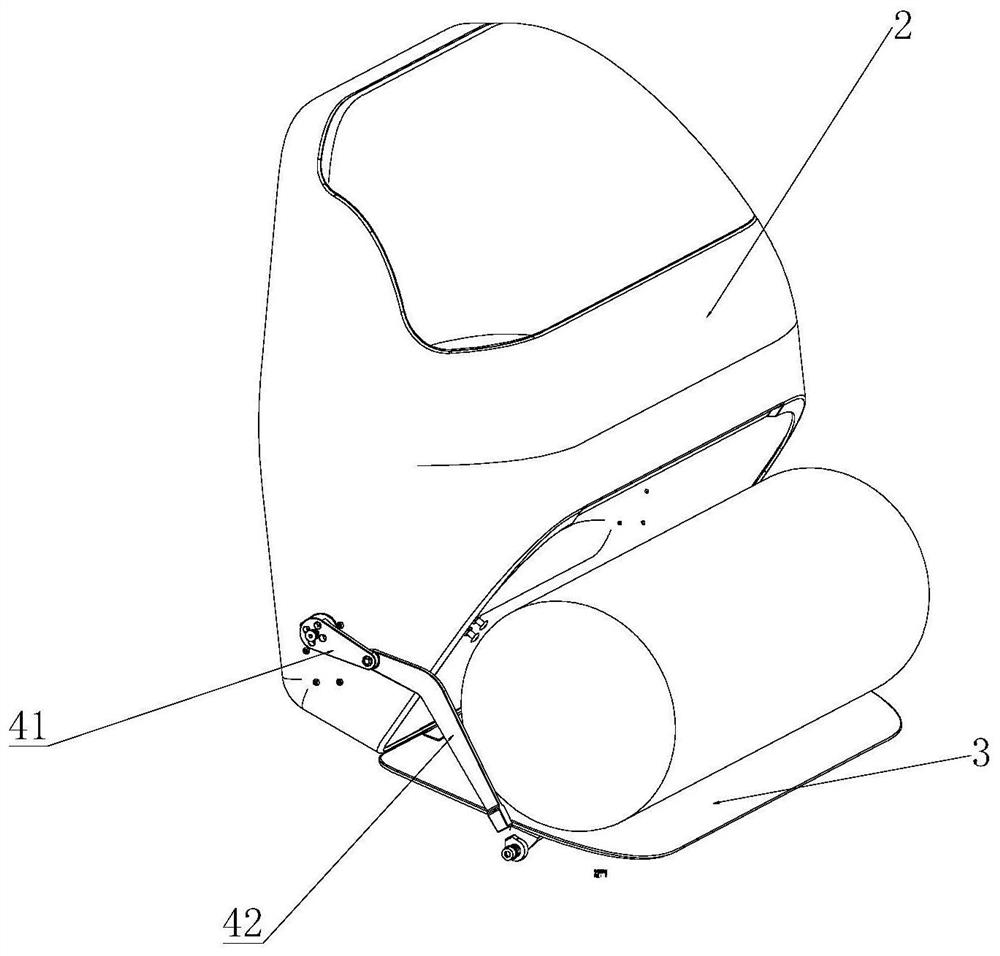

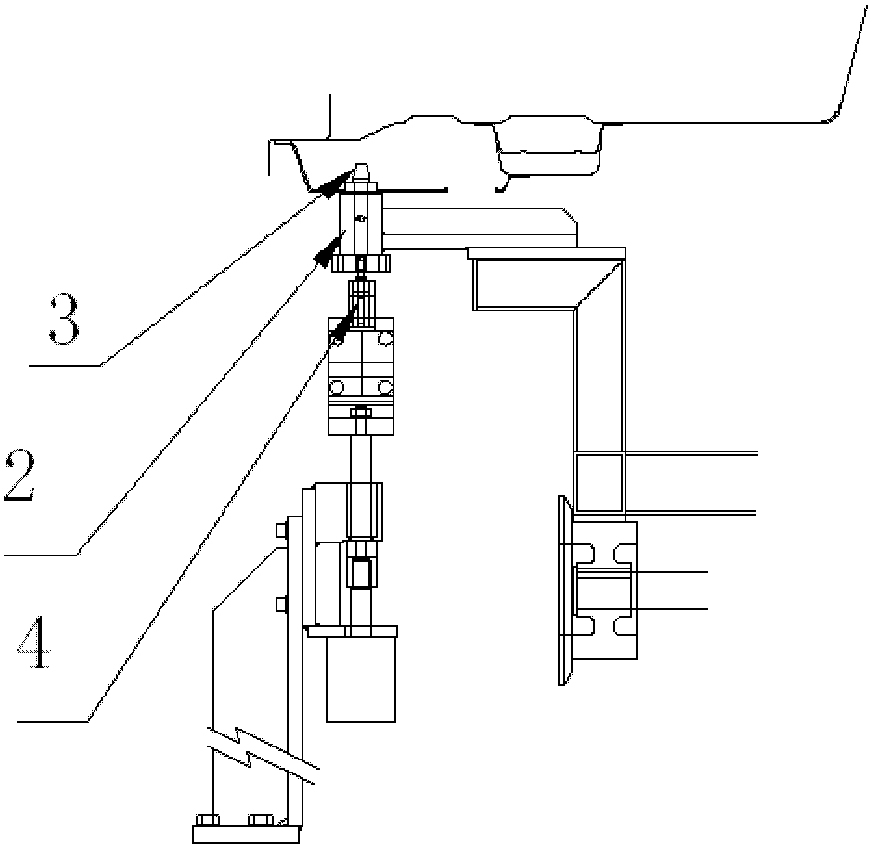

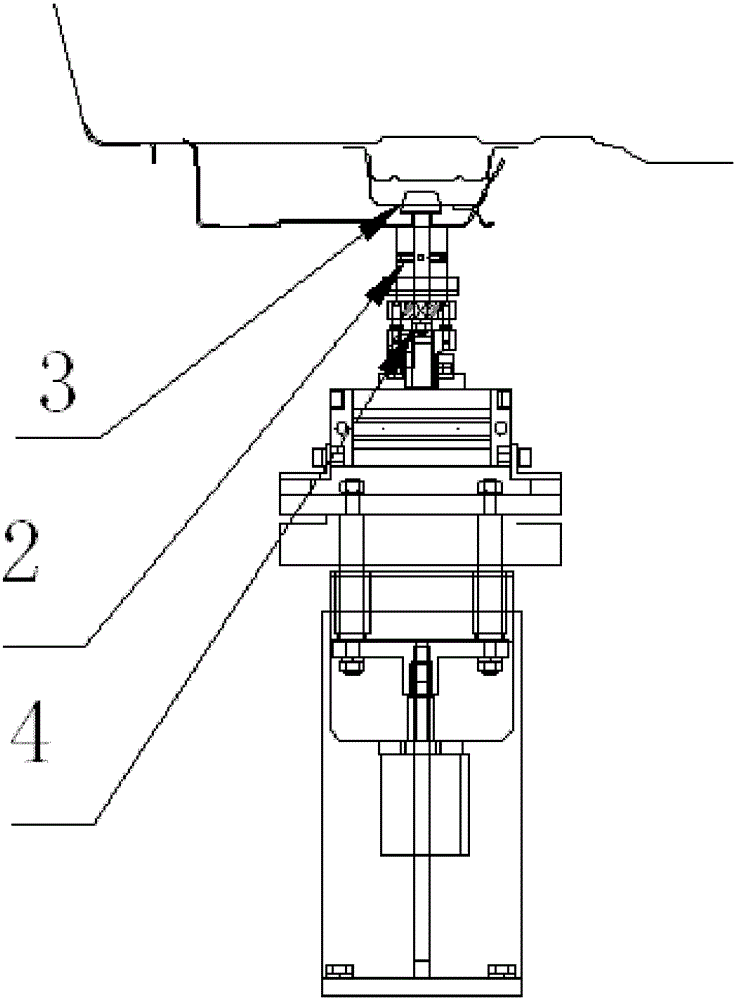

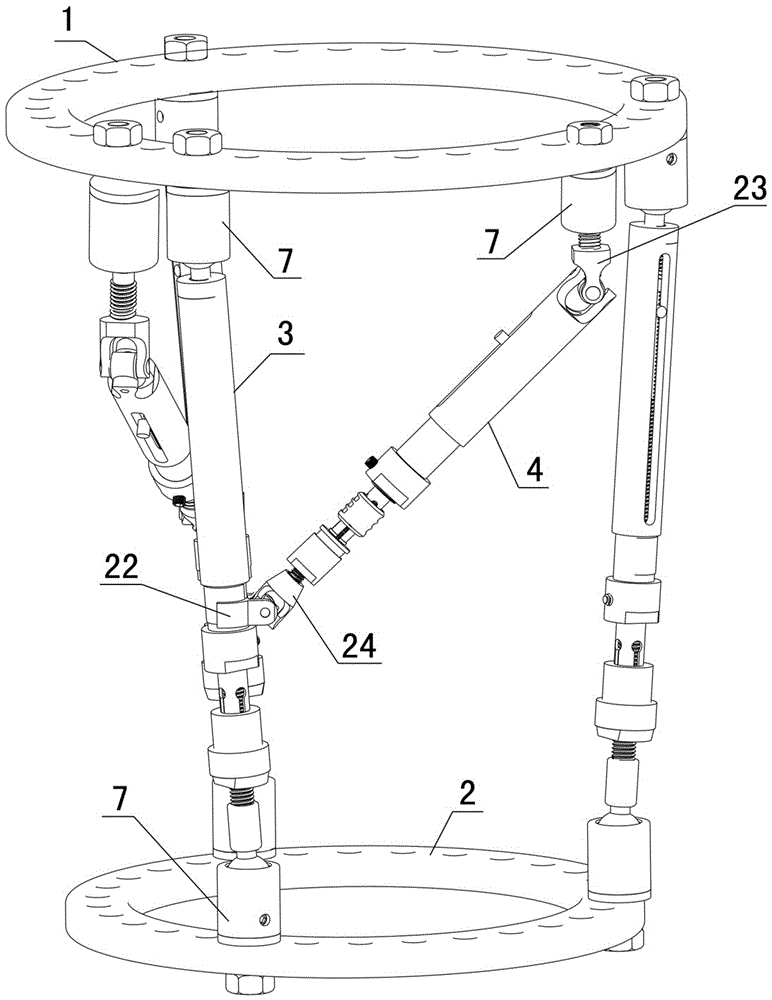

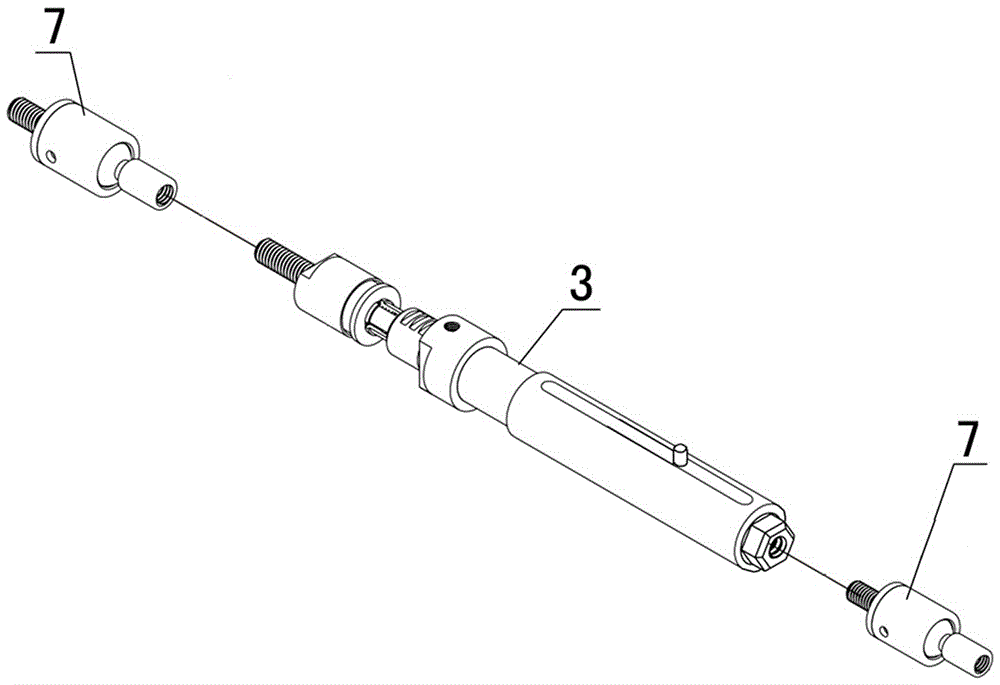

Support regulating device and assembling tool

InactiveCN108237499ASimple structureEasy to operateWork holdersMetal-working hand toolsEngineeringMechanical engineering

The invention provides a support regulating device and an assembling tool. The support regulating device comprises a base, a height adjusting assembly and a top support assembly which are sequentiallyconnected, wherein the top end of the top support assembly is provided with universal balls; the height adjusting assembly comprises a lever and a connector in thread connection with the lever; the connector is located on the base; the lever is connected with the top support device; and the lever can rotate relative to the connector around the self axis so as to drive the top support assembly tostretch and retract relative to the base. The support regulating device provided by the invention can solve the problems that support height cannot be regulated and the surface of a workpiece is wornwhen the position is adjusted in the prior art.

Owner:CRRC TANGSHAN CO LTD

Sliding pry in improved structure

Owner:苏州诺克汽车工程装备有限公司

Circuit breaker gas-taking auxiliary device

ActiveCN105304397AEasy accessSimple structureHigh-tension/heavy-dress switchesAir-break switchesEngineeringCam

The invention discloses a circuit breaker gas-taking auxiliary device. The device comprises a rack, the rack is provided with a press block capable of sliding up and down along the rack, a cushion block matched with the press block is fixedly arranged on the bottom end of the rack, the top end of the rack is provided with a rotatable cam, when the cam rotates, the contour line of the cam is contacted with the press block and the cam drives the press block to slide up and down along the rack. The device disclosed by the invention has the advantages of being simple in structure, convenient and fast in operation and good in clamping effect.

Owner:STATE GRID CORP OF CHINA +2

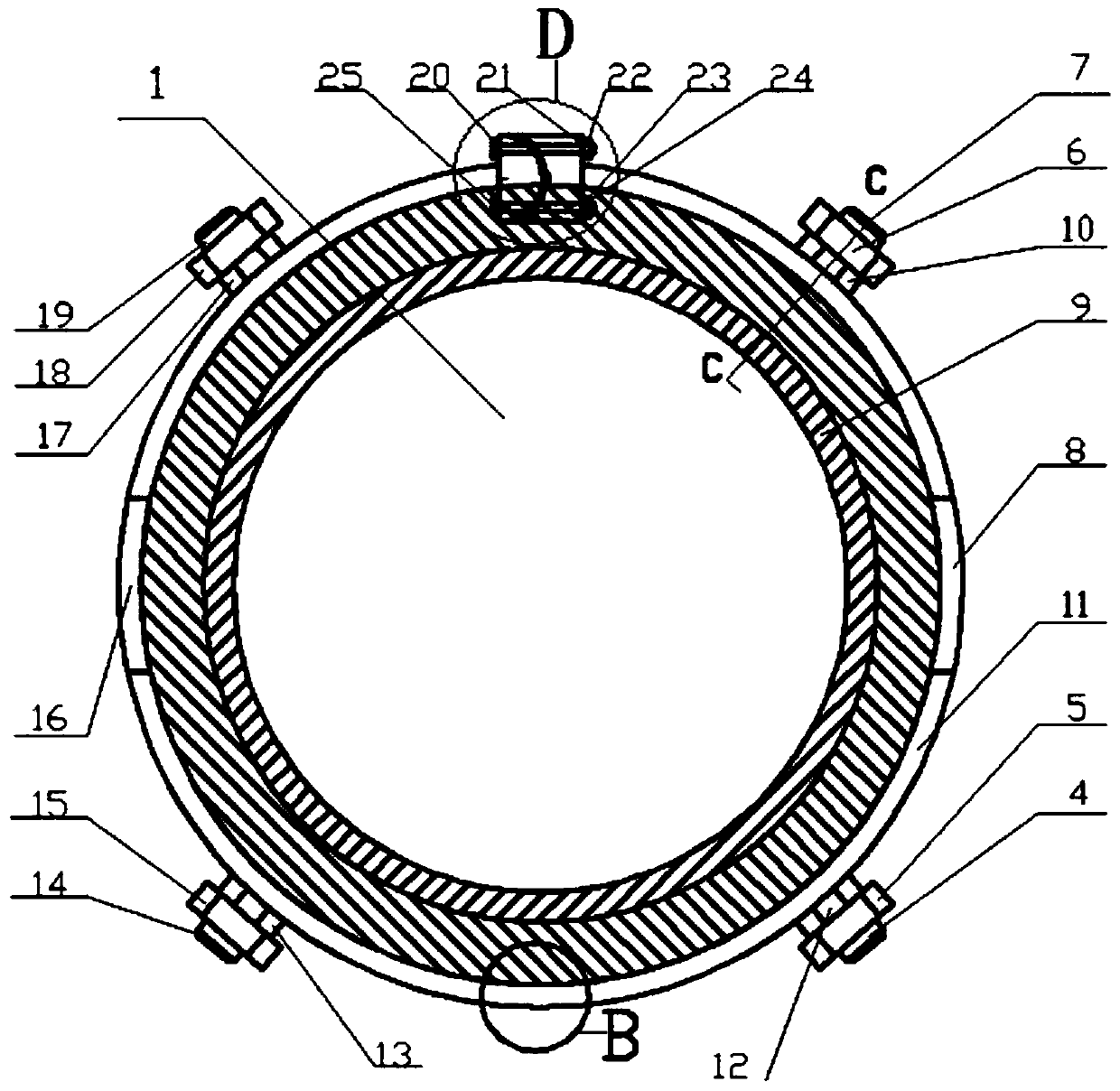

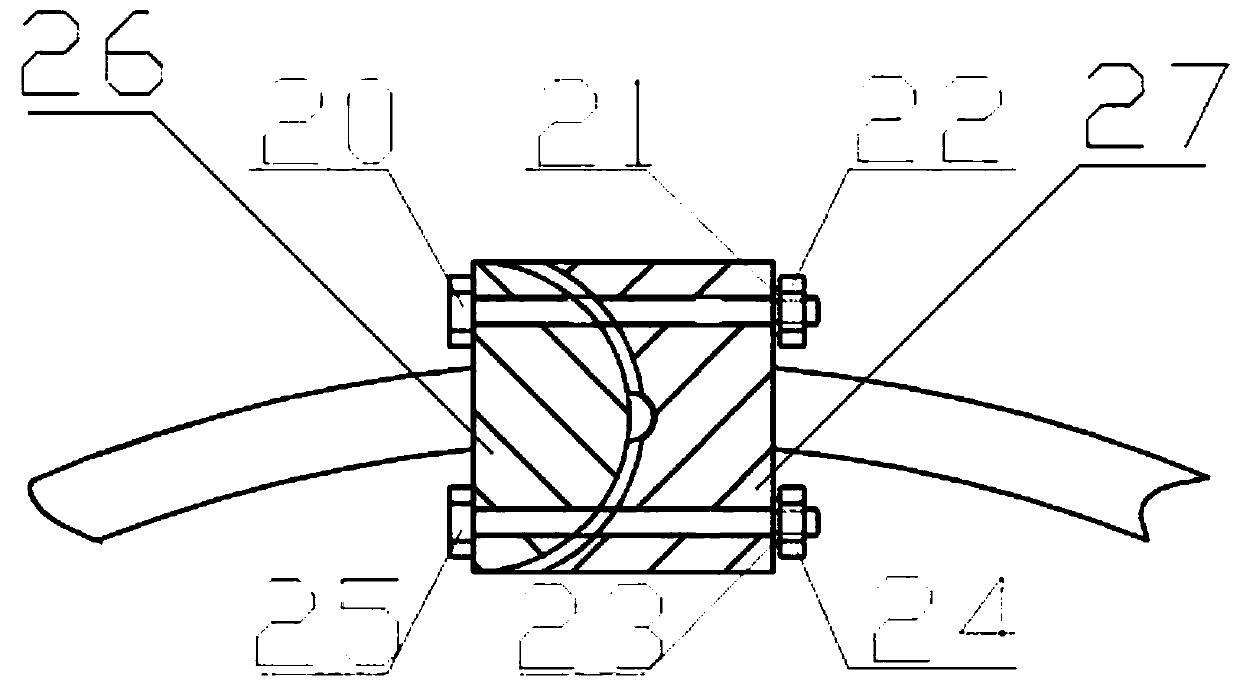

Removable ring steel wire rope fixing mechanism

InactiveCN109704219AEasy to assemble and disassembleThe disadvantages of avoiding harmWinding mechanismsMating connectionEngineering

The invention discloses a removable ring steel wire rope fixing mechanism. The mechanism comprises a steel wire rope, and a reel, wherein the steel wire rope winds around the reel; the mechanism is characterized in that the mechanism further comprises a ring fixing mechanism; a reel interval is arranged between a first section of the steel wire rope on the reel and a second section of the steel wire rope on the reel; the reel is sleeved with the ring fixing mechanism; and both ends of the top of the ring fixing mechanism are movably in fit connection with a fixed concave round block, which isfixedly arranged on the ring fixing mechanism, through a rotatable rotating convex round block. According to the mechanism, the ring fixing mechanism is used for compressing and fixing, both ends of the top of the ring fixing mechanism are movably in fit connection with the fixed concave round block through the rotatable rotating convex round block, so that the contact area is larger, and the connection is more stable; and at the same time, a self-locking function is added to avoid injury of the body of the construction worker caused by relieving and instantaneously releasing a constraining force in fixing a press plate of a traditional steel wire rope, and thus, the mechanism is safer.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

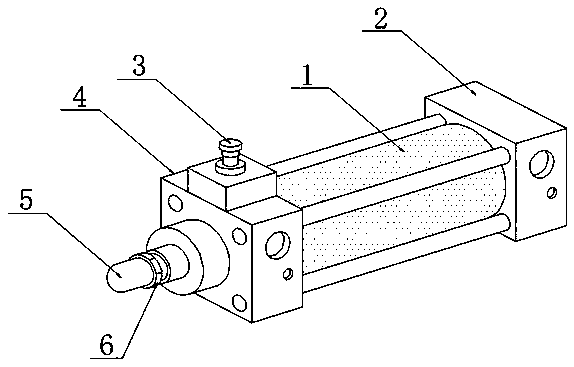

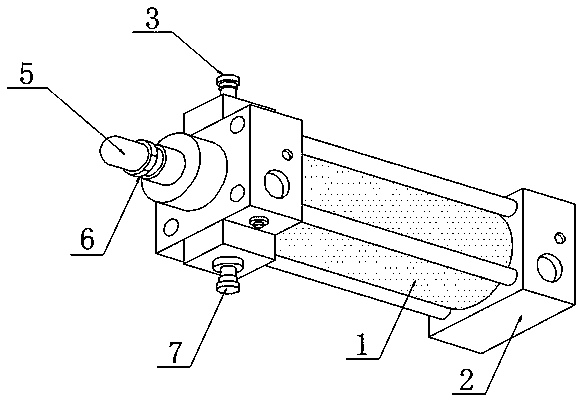

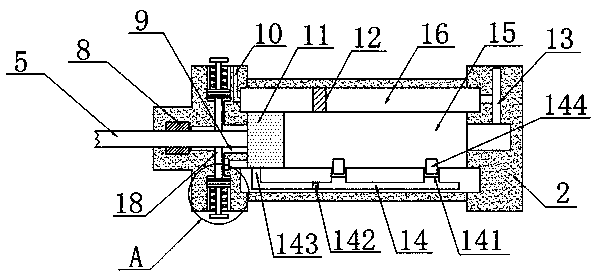

Cylinder with double self-locking structure

PendingCN109058229AImprove the quality of useAdd self-locking functionFluid-pressure actuatorsPneumatic pressureEngineering

The invention discloses a cylinder with a double self-locking structure. The cylinder with the double self-locking structure comprises a cylinder body. A rear end cover is arranged at the rear end ofthe cylinder body. A front end cover is arranged at the front end of the cylinder body, and a handle is arranged at the position, located at the upper end of the front end cover, of the front end of the cylinder body. A piston rod is arranged on the front surface of the front end cover. The cylinder with the double self-locking structure enables air pressure in an accommodating cavity and a firstouter air cavity to be complementary to air pressure at the front end of an inner piston, and the internal air pressure of the cylinder with the double self-locking structure is constant. When the inner piston moves forward, the air pressure at the front end of the inner piston is pushed into the accommodating cavity and the first outer air cavity, so that a brake piston is just moved downward, abrake rod is pulled out of an embedded hole of the piston rod surface, and a limiting rod is pushed upward, so that the inner piston is locked and limited, and when the inner piston retracts, the airpressure drives the brake rod to be embedded into the embedded hole of the piston rod, and meanwhile, the limiting rod is retracted downward, the limiting and locking of the inner piston is released,and the brake rod is matched with the limiting rod, so that a double self-locking function for the cylinder is achieved.

Owner:山东百帝气动科技股份有限公司

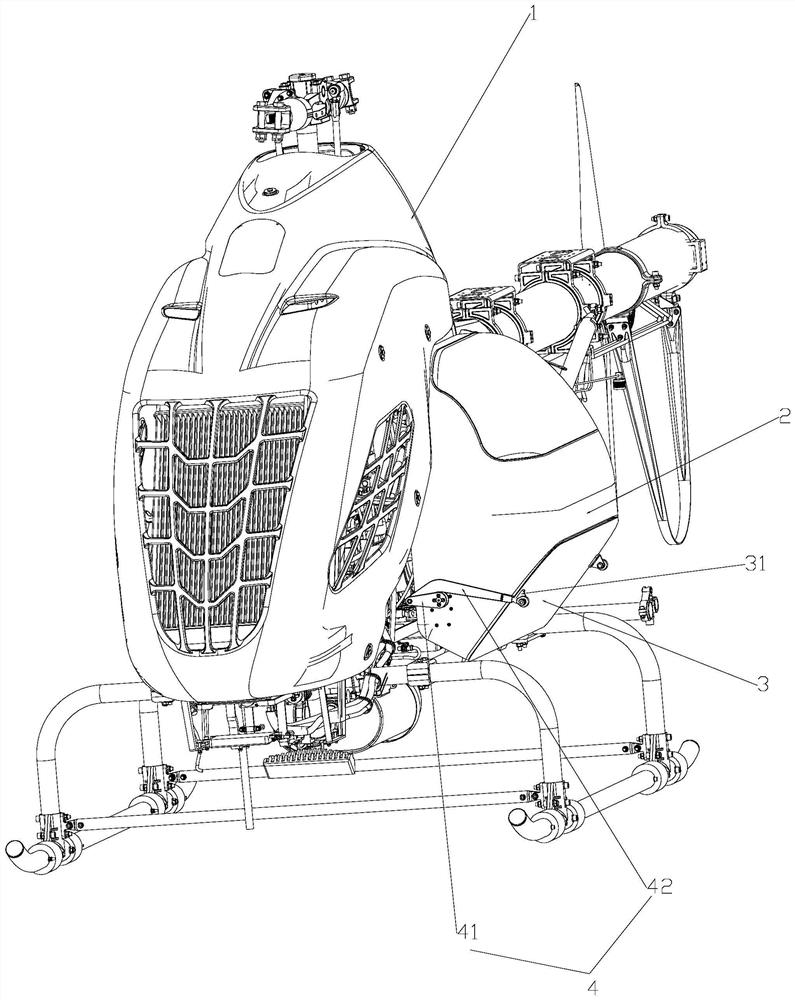

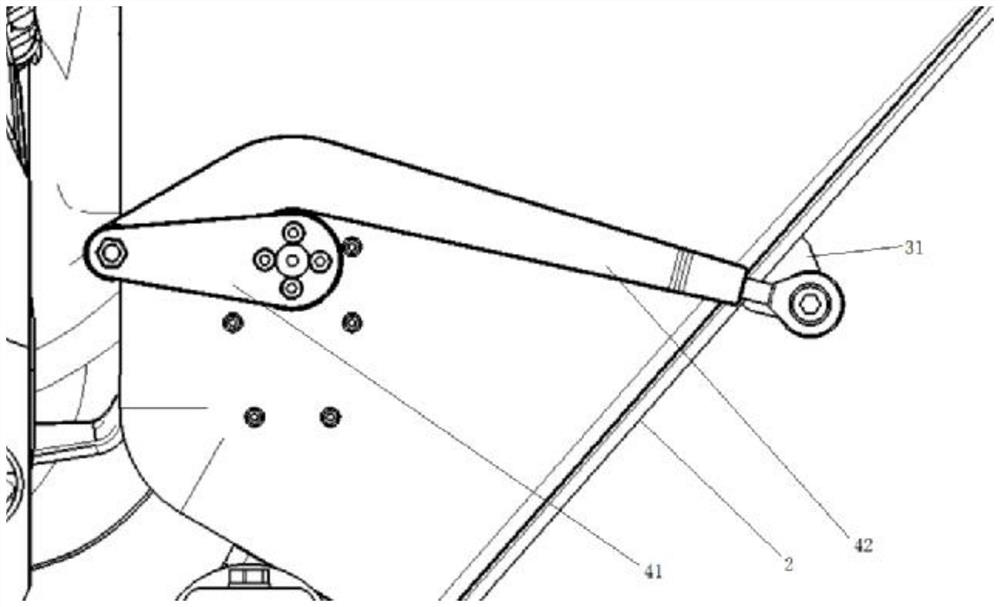

Unmanned aerial vehicle delivery system and delivery method thereof

PendingCN112009688AOvercome low load capacityIncreased carrying capacity and battery lifeFreight handlingTarget-seeking controlAutomotive engineeringAerospace engineering

The invention discloses an unmanned aerial vehicle delivery system comprising a vehicle body, a transporting cabin arranged on the side face of the vehicle body, a lower turning plate hinged to a throwing opening of the transporting cabin, and a self-locking adjusting mechanism arranged between the transporting cabin and the lower turning plate and used for achieving self-locking of the lower turning plate. According to the unmanned aerial vehicle delivery system and the delivery method thereof, goods and materials can be effectively transported and thrown to a target area in a short time, thedefects that an existing unmanned aerial vehicle transporting and throwing system is low in load capacity and short in endurance time are overcome, the carrying capacity of the transporting and throwing system is improved, and the endurance time of the transporting and throwing system is prolonged; compared with the prior art, the unmanned aerial vehicle delivery system has obvious advantages inthe face of a dangerous environment and a large-span terrain, meets the material transportation and delivery function in a complex environment and a high-risk environment, adds a self-locking functionto the transportation cabin, triggers fault protection under abnormal conditions, and reduces the power supply voltage of the steering engine through a program, thereby achieving protection and further ensuring that materials cannot fall out of the transportation cabin.

Owner:重庆领直航科技有限公司

A self-locking bolt

The invention belongs to the technical field of fastening pieces, in particular to a self-locking bolt. The self-locking bolt comprises a first bolt, an elastic module and a second bolt; a first thread hole and a second thread hole are formed in the first bolt; the first thread hole is positioned in the first bolt; the second thread hole is positioned at the lower end of the first bolt; the firstbolt is an external hexagonal bolt; the elastic module is positioned at the middle part of the first bolt; the elastic module adopts a material of spring steel; the elastic module is one part of the first bolt; the first bolt is used for bolt self-locking; the second bolt is an internal hexagonal bolt, and is fixed in the first bolt through the first thread hole; the lower end of the second bolt is contacted with the upper end of the elastic module; and the second bolt is used for extruding the elastic module.

Owner:GUANGZHOU BAOSTEP IND LTD

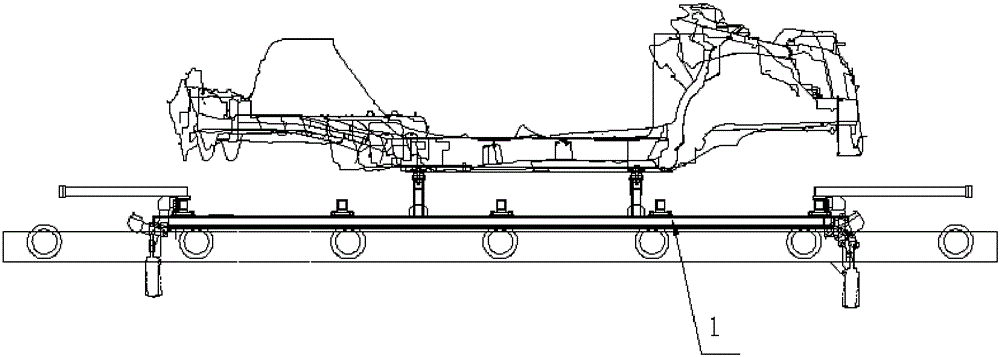

Structurally Improved Skid

ActiveCN103129925BAvoid rollover hazardsAdd self-locking functionMechanical conveyorsEngineeringMechanical engineering

Owner:苏州诺克汽车工程装备有限公司

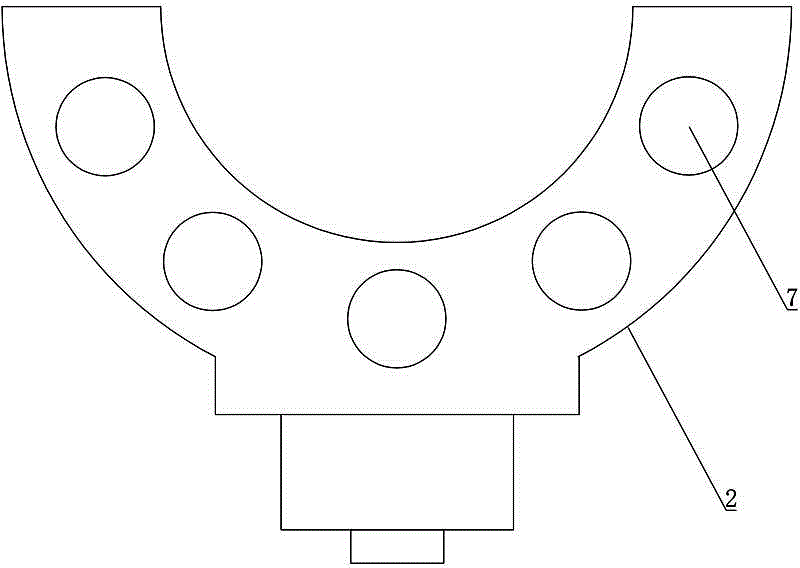

A kind of shuttle for mining trolley

ActiveCN106477471BAdd self-locking functionPlay a protective effectWinding mechanismsSelf lockingEngineering

The invention relates to a shuttle for a mining trolley and belongs to the mining field. The shuttle comprises a main body, wherein the main body comprises a touch plate and a bottom plate; the touch plate is perpendicularly fixed on the bottom plate to enable the main body to be T-shaped; a transparent rope penetrating groove is formed in the middle of the main body and takes a wedge-shape structure with the opening gradually reduced from the bottom plate to the touch plate; a groove is formed in the groove side on one side of the rope penetrating groove; the end, close to the bottom plate, of the groove is an opening end, and the other end of the groove is a blind end; a wedge block capable of sliding in the rope penetrating groove is mounted in the groove; and a plurality of fixing holes are formed in the bottom plate on two sides of the touch plate. A self-locking function is added for the shuttle, so that on one hand, the shuttle can share part of tensile force of a steel wire rope, and on the other hand, the steel wire rope does not slide in the shuttle due to the self-locking function even if a rope fastening device has an accident or is damaged, as a result, a shuttle car does not slide to realize a protection function.

Owner:SHANGHAI DATUN ENERGY

Spherical universal joint and adjustable bionic external fixator for bone external fixator

ActiveCN103006302BKeep free spinsAdd self-locking functionExternal osteosynthesisExternal fixatorUniversal joint

The invention relates to a spherical universal joint for an external bone fixator and a regulating type bionic external bone fixator. The spherical universal joint for the external bone fixator comprises a spherical head, a sleeve, a sleeve cover, a ball slot, a ball bowl, a locking shaft and a locking slide block, wherein the spherical head comprises a joint ball and a threaded type spherical universal joint connector A arranged on the joint ball, the joint ball is arranged on the inner side of the sleeve, the side of the joint ball close to the threaded type spherical universal joint connector A is contacted with the arc-shaped surface of the sleeve, the threaded type spherical universal joint connector A extends out of one end of the sleeve, the sleeve cover is fixedly connected with the other end of the sleeve, the outer side face of the sleeve cover is provided with a threaded type spherical universal joint connector B, and the inner side face of the sleeve cover is provided with a groove for arrangement of the locking slide block. The regulating type bionic external bone fixator with the spherical universal joint has the advantages of simple structure, light weight, low cost, regulating capability and flexible operation, and targeted and personalized combination and regulation can be realized.

Owner:夏和桃

Hydraulic forming equipment

A hydraulic forming device, including a supercharged device for supplying liquids to the processing parts. The booster device includes a booster mechanism used to pressure the low -pressure liquid to high pressure liquid, and the driver mechanism for providing power to the supercharged mechanism; The supercharged mechanism includes the first piston that can be inserted inside the first cylinder tube, the first piston is closed in the inner wall of the first cylinder, and the first piston and the first cylinder cylinderThere is a storage cavity between the inner walls. There is an exit connected to the liquid storage cavity on the first cylinder.; Drivers include motors, screws, nuts that meshing with screws, any of the two components of screw and nuts connected to the motor, and the other movement direction is connected to the first piston transmission.It is a self -locking system and facilitated controlling device, which is a good guarantee to ensure the quality of the workpiece during the hydraulic processing process.

Owner:庄添财

Reversible bucket

InactiveCN1294058CIncreased discharge rangeNo inversionLoading/unloadingManipulatorReduction driveReducer

An overturnable scopper is composed of motor, worm-gear speed reducer and its holder fixed to swinging arm of robot, bevel gear A fixed to output shaft of speed reducer, rotary axle, bevel gear B fixed to said rotary axle, and scooper fixed to said rotary axle.

Owner:SHANGHAI JIAOTONG UNIV

An axial buckle joint

The invention relates to an axial buckling and pressing connector. The axial buckling and pressing connector comprises an intra-pipe glue layer, a framework layer and an extra-pipe glue layer which are all of cylindrical structures and are sequentially connected in a sleeved manner from inside to outside to form a pipe body; the intra-pipe glue layer and the framework layer extend out of the pipe body from the same end, and the framework layer is made of flexible materials; the buckling and pressing connector further comprises an outer pressing ring and an inner pressing ring, the front end of the extending-out end of the intra-pipe glue layer is sleeved with the outer pressing ring, and the back section of the framework layer is sleeved with the inner pressing ring; and the outer pressing ring, the front section of the framework layer, the inner pressing ring and a piston flange are sequentially pressed in a butting manner from the extending-out end to the other end in the axial direction of the pipe body and are integrally molded through vulcanization. Compared with a flexible connecting pipe with the same length, a connecting structure adopting the connector and the pipe body is characterized in that the connector size is small, the flexibility section of the pipe body is long, the structure is simple, installation is flexible, and the connector and the pipe body are more firmly combined through vulcanization integrated molding. The technical problems that a traditional axial buckling and pressing connector is low in connecting strength, poor in pulling and dropping resistance and free of the self-locking function are solved.

Owner:NAVAL UNIV OF ENG PLA +1

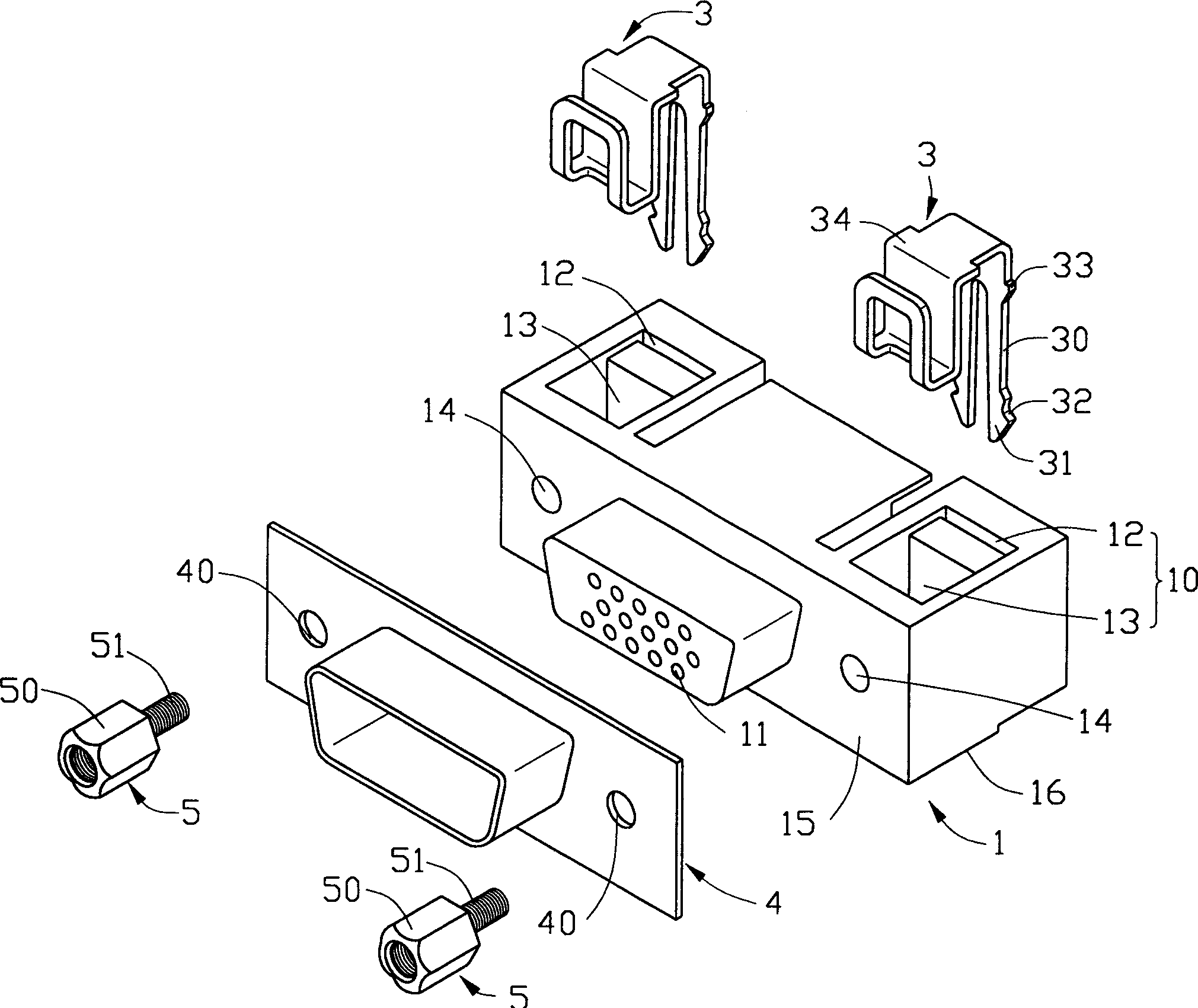

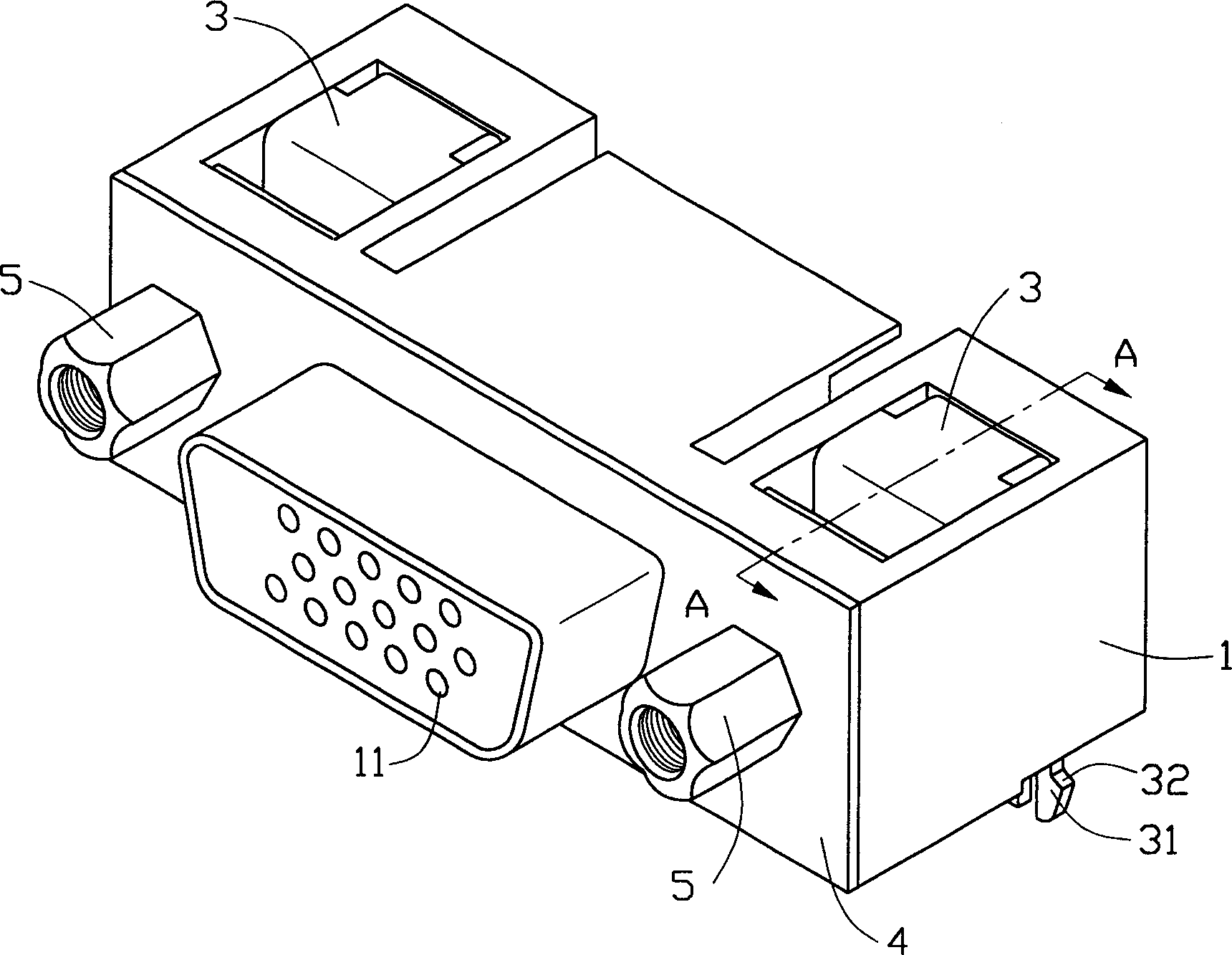

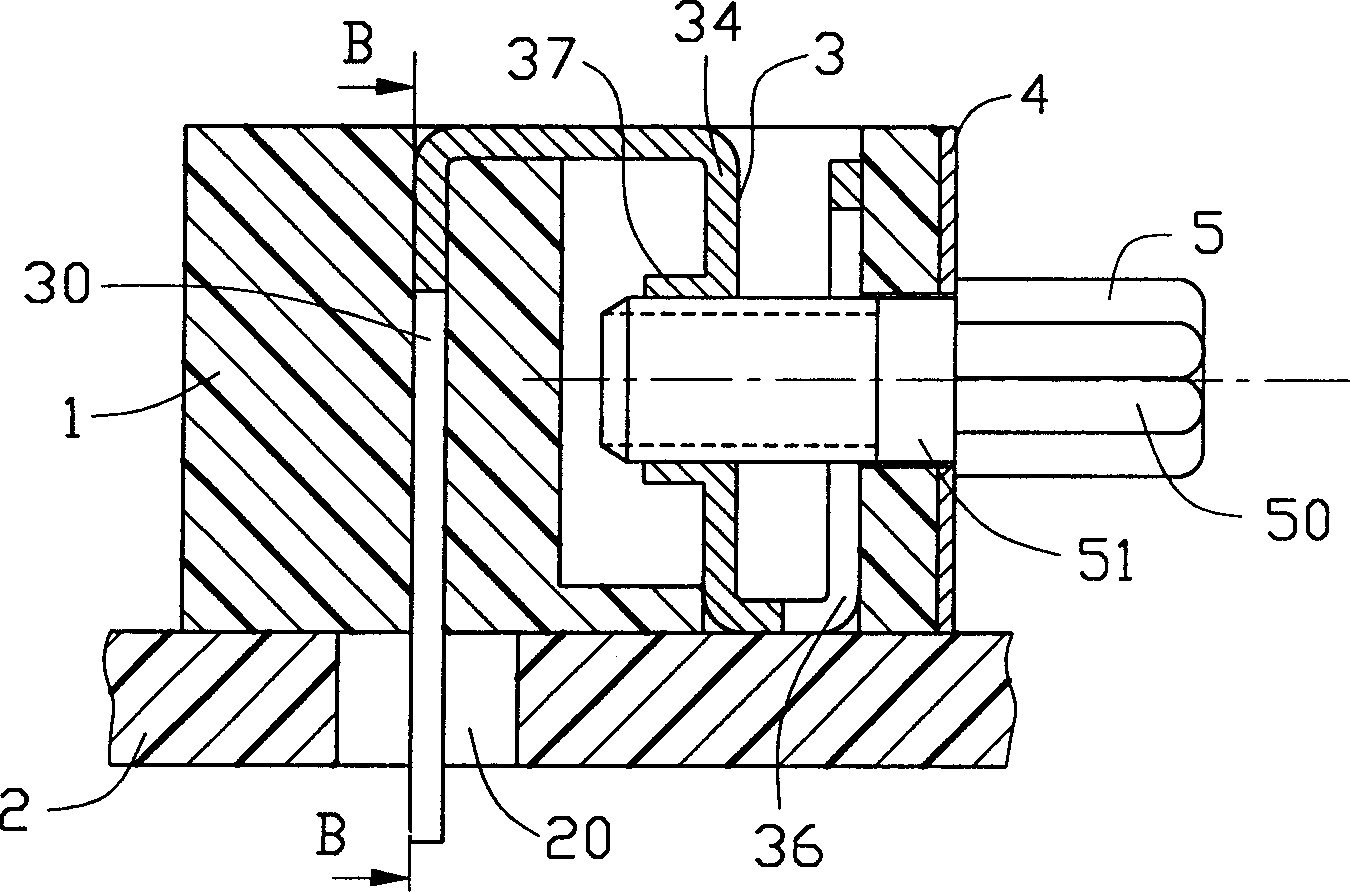

Electric connector and its locking device

InactiveCN1129211CFunction increaseSimple structureCoupling parts mountingSelf lockingScrew retained

The present invention relates to an electric connector. It is equipped with a locking device consisting of existent fastening member (fastening pin) and screw-retaining member, and its utilizes a special structure to implement self-locking function. Said locking device includes fastening member and retaining member, in which the fastening member includes fixing portion and fastening pin, said fixing portion is received in the described assembly connected space of the insulating self-body, and is a multibent structure, on which the assembly-connecting hole is opened, and the fastening pin is extended from one end of fixing portion so as to fix the electric connector to printed circuit. Said retaining member possesses the assembly-connecting portion matched with assembly-connecting hole of fixing portion so as to make the fastening member obtain self locking function.

Owner:FOXCONN (KUNSHAN) COMPUTER CONNECTOR CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com