Removable ring steel wire rope fixing mechanism

A fixing mechanism and wire rope technology, which is applied in the field of detachable ring-type wire rope fixing mechanism, can solve the problems that construction workers are vulnerable to physical injuries, and achieve the effects of material saving, stable connection and increased self-locking function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

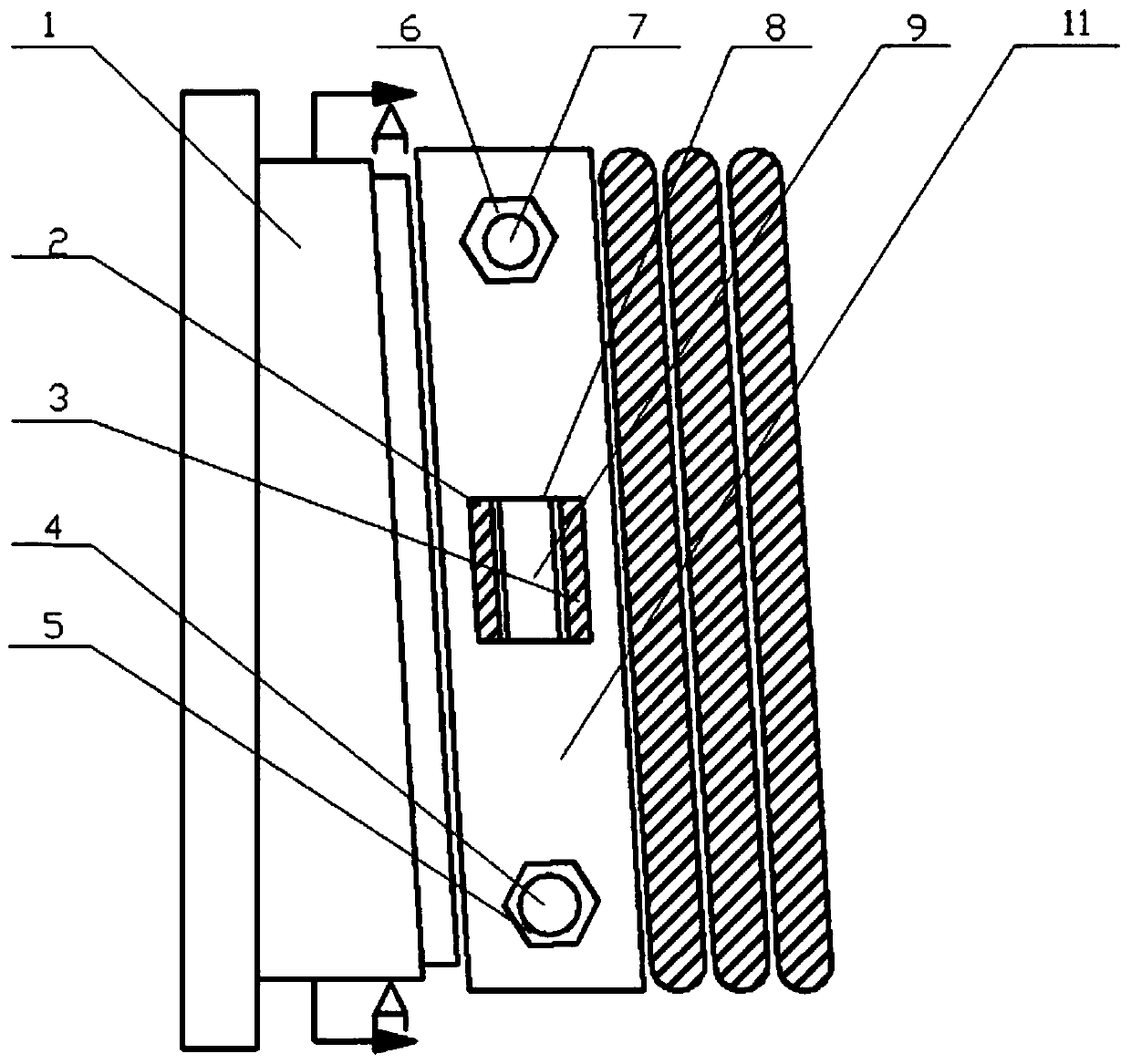

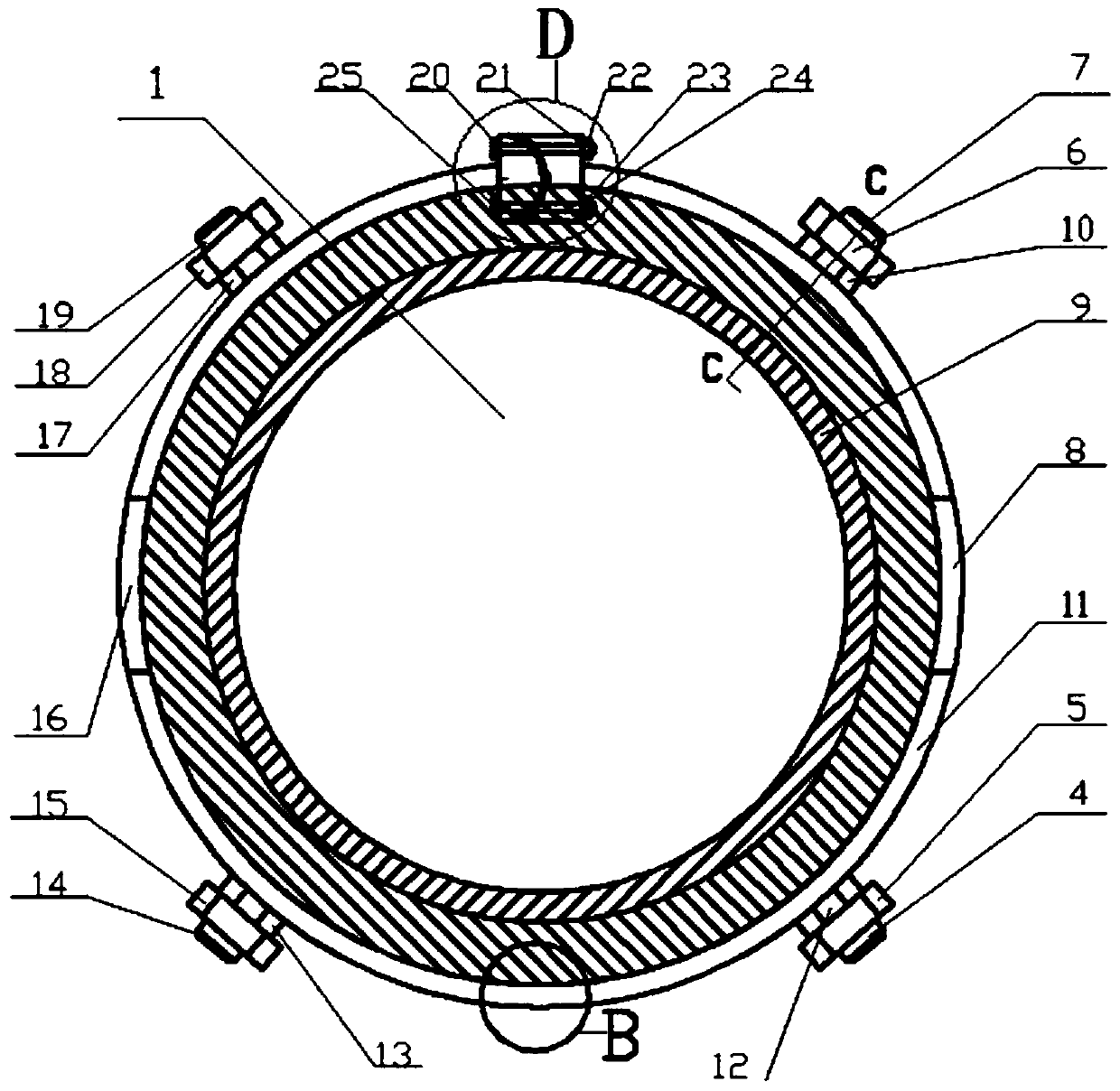

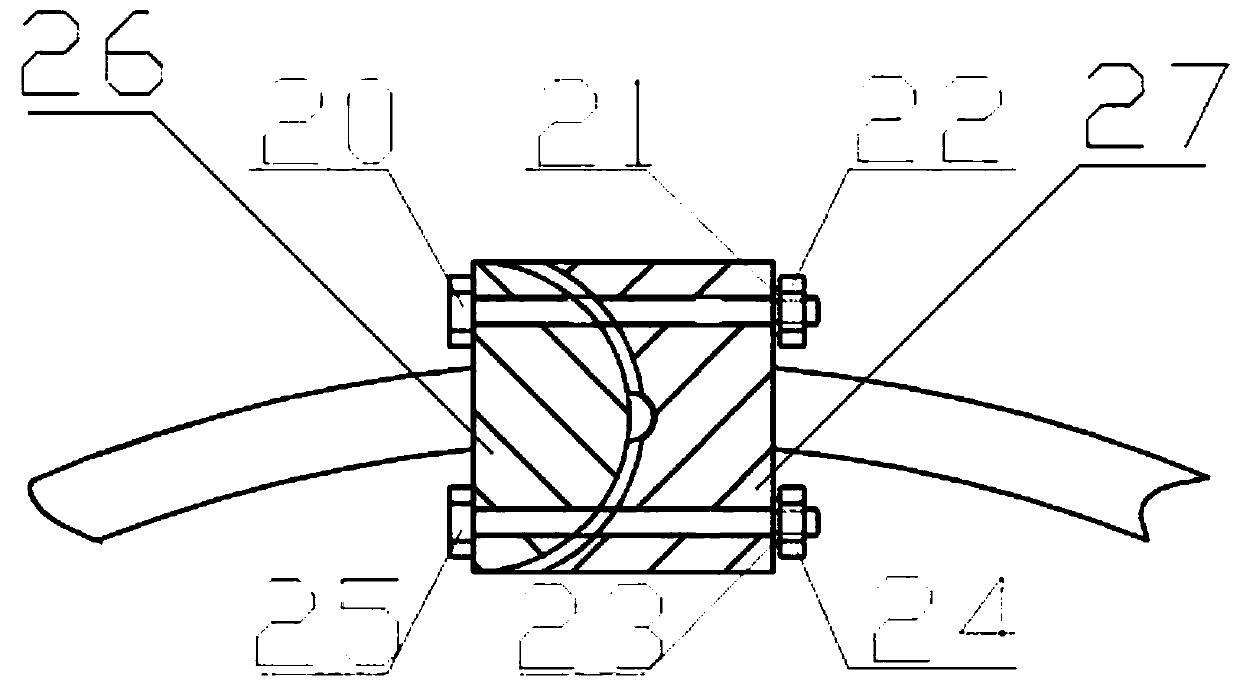

[0022] like figure 1 and figure 2 As shown, the present invention proposes a detachable ring type wire rope fixing mechanism, including a wire rope and a reel 1, and the wire rope is wound on the reel 1, and is characterized in that it also includes a ring fixing mechanism 11, and the wire rope is on the reel 1 There is a reel gap 9 between the first section of steel wire rope 2 and the second section of steel wire rope 3, and the ring fixing mechanism 11 is set on the reel 1, and the top two ends of the ring fixing mechanism 11 adopt rotatable rotating convex blocks 26 is detachably connected with the fixed concave round block 27 fixed on the ring fixing mechanism 11, the contact area is lar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com