Self-locking puller with double horse hooks

A horse hook and self-locking technology, applied in the field of zipper heads, can solve the problems of shortening the service life of self-locking zipper heads, automatic sliding and self-locking, poor self-locking function, etc., achieving good self-locking effect, firm and reliable self-locking, and improved The effect of the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

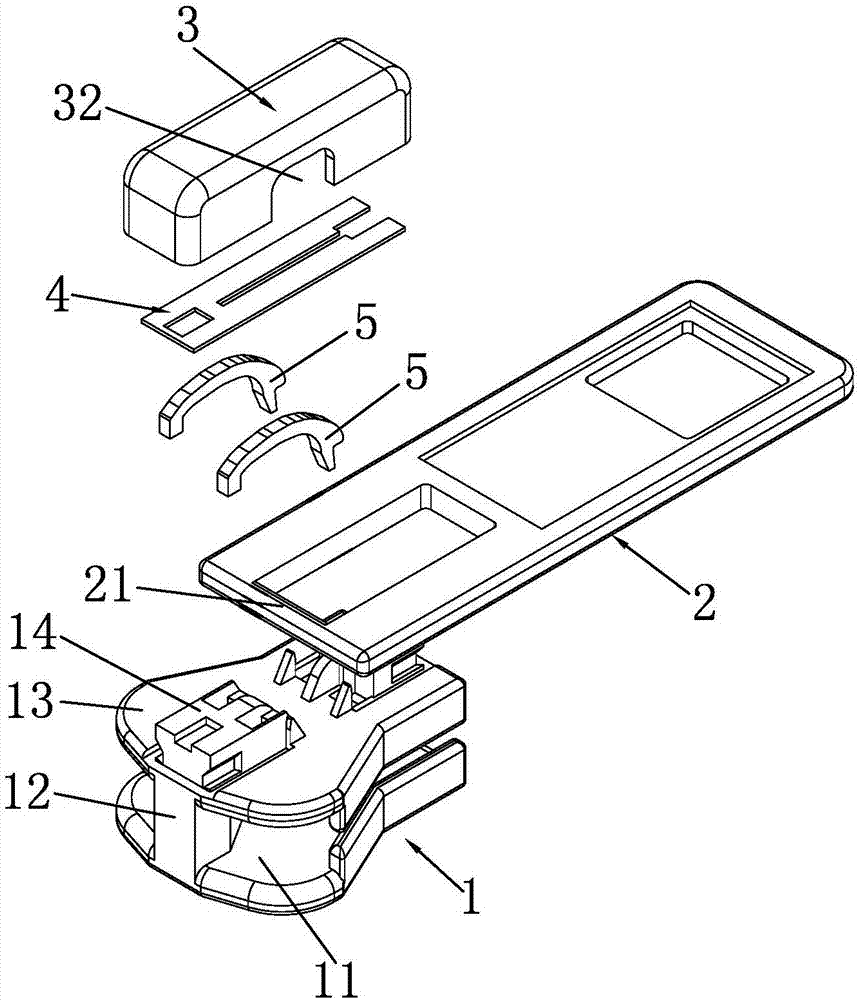

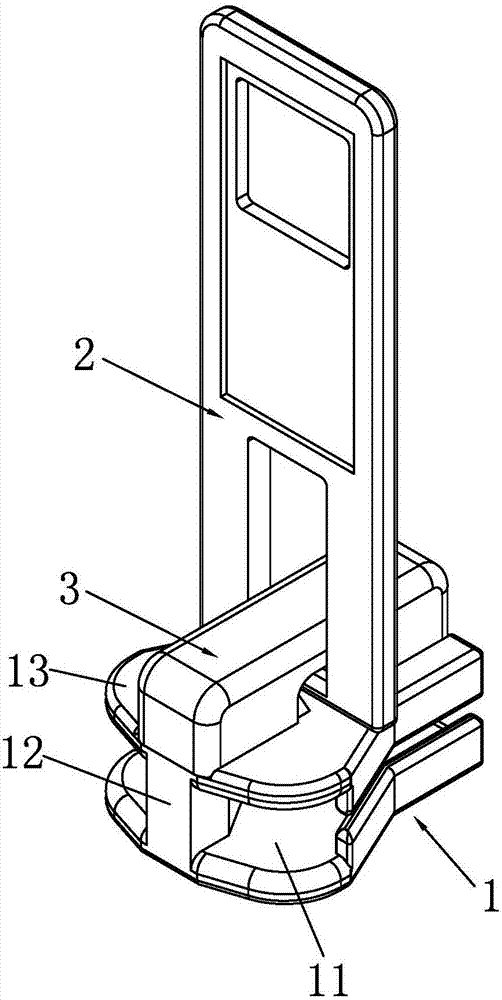

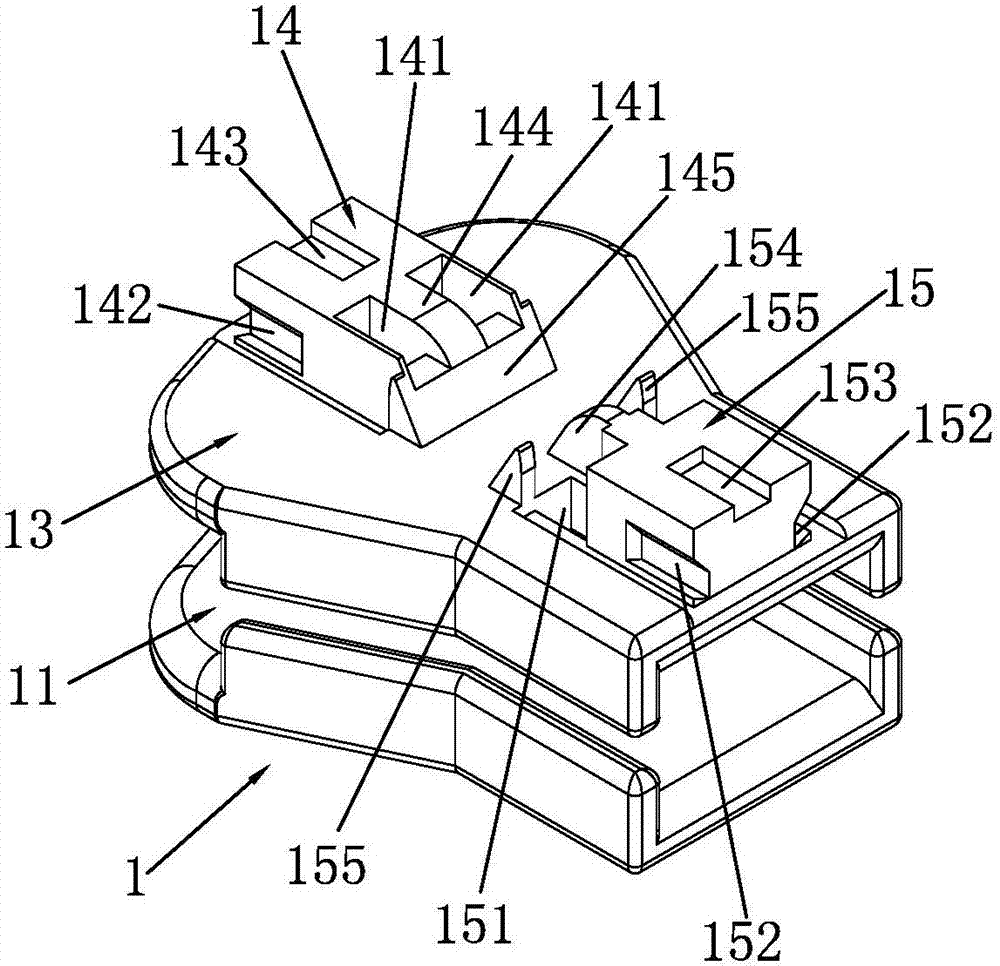

[0023] Such as Figure 1 to Figure 7 As shown, a self-locking slider with double horse hooks includes a slider body 1, a pull piece 2, a cap 3, a shrapnel 4 and two horse hooks 5. The slider body 1 is composed of a lower wing plate 11, a guide post 12 is connected with the upper wing plate 13, the front end of the top surface of the upper wing plate 13 is provided with a front mounting part 14, the top rear end of the upper wing plate 13 is provided with a rear mounting part 15, and the pivot 21 of the pull piece 2 is arranged on the front Between the mounting part 14 and the rear mounting part 15, the cap 3, the shrapnel 4 and two horse hooks 5 are mounted on the front mounting part 14 and the rear mounting part 15, so that the shrapnel 4 presses the tops of the two horse hooks 5.

[0024] Such as Figure 1 to Figure 3 As shown, the front mounting part 14 is provided with two first mounting holes 141 for assembling the horse hook 5 in parallel, a first partition 144 is arran...

Embodiment 2

[0030] Such as Figure 8 and Figure 9As shown, on the basis of Embodiment 1, the groove positioning structure on the top of the front mounting part 14 and the rear mounting part 15 of the slider body 1 is set as an upwardly protruding positioning structure, specifically: in the front mounting part The top of 14 is provided with first positioning projection 146, and the top of rear mounting part 15 is provided with second positioning projection 156, and the structure of first positioning projection 146 and second positioning projection 156 are identical, and both are square projections. block; and the inside of the cap 3 does not need to be provided with a positioning structure corresponding to the first positioning protrusion 146 and the second positioning protrusion 156 . The assembly process of the self-locking slider in Example 2 is basically the same as that of the self-locking slider in Example 1, the only difference is that in Example 1, the shrapnel 4 is first assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com