An axial buckle joint

A crimping joint, axial technology, applied in the direction of pipes/pipe joints/fittings, adjustable connections, passing components, etc., can solve the problems of low connection strength, no self-locking function, poor pull-off resistance, etc., and meet the installation accuracy requirements Low, strengthen self-locking function, not easy to aging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

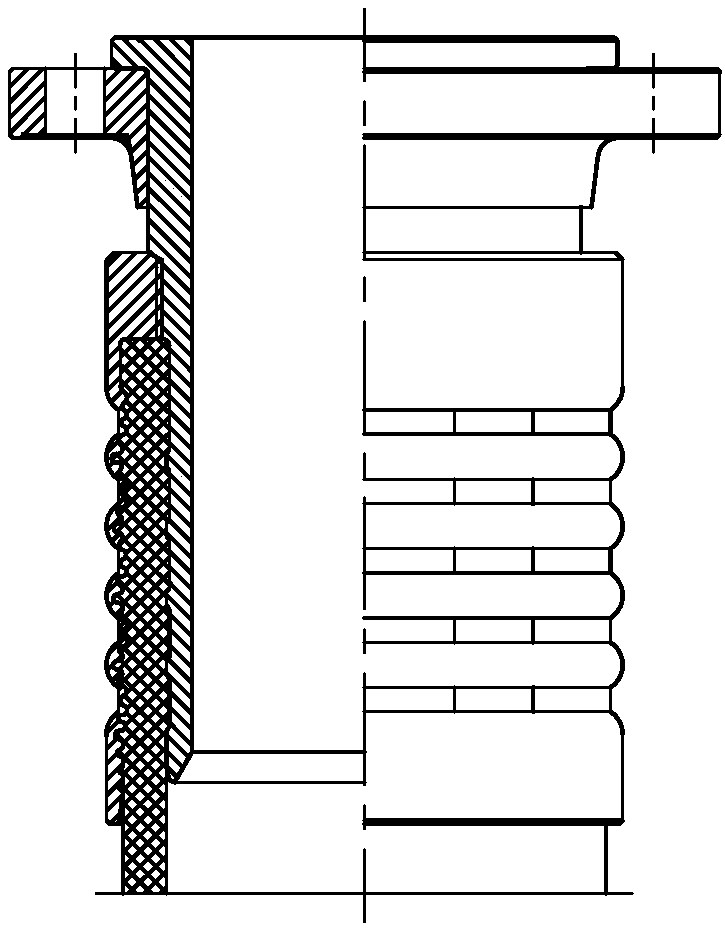

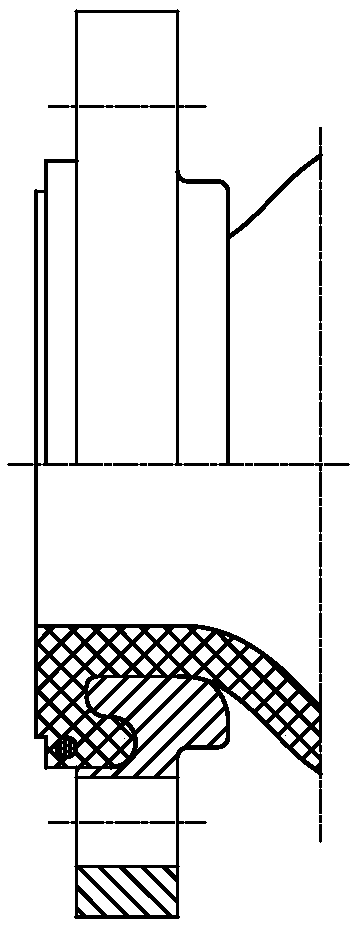

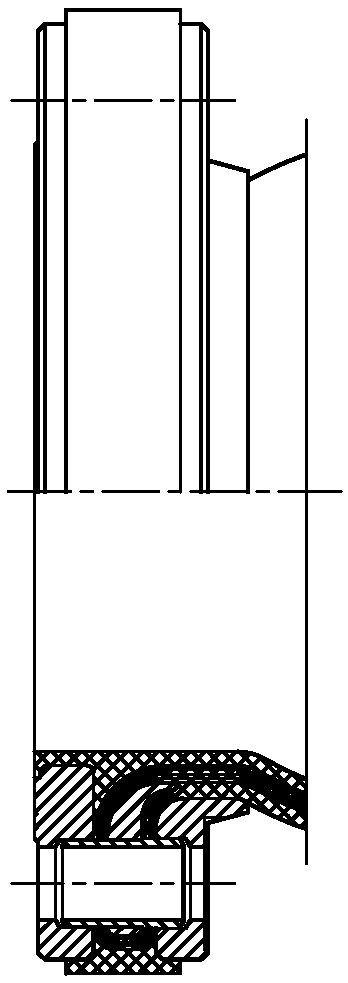

[0035] see Figure 4-8 As shown, an axial crimping joint includes a looper flange 1 and a flexible pipe body 10; the looper flange 1 is a flange structure, and the flexible pipe body 10 includes inner rubber in turn from the inside to the outside layer 2, skeleton layer 3, and outer rubber layer 4, the crimp joint is located at the end of the flexible pipe body 10,

[0036] The buckle joint also includes an outer pressure ring 5 and an inner pressure ring 6, the outer pressure ring 5 and the inner pressure ring 6 are annular sleeve structures, and the outer pressure ring 5 is sheathed on the end of the flexible pipe body 10. Outside the inner rubber layer 2, an annular boss 21 is provided outside the end of the inner rubber layer 2, and the inner ring end of the outer pressure ring 5 is provided with a corresponding annular depression 51, and the boss 21 is embedded The sealing structure between the joint and the conveying medium in the pipe is formed in the depression 51; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com