Hydraulic forming equipment

A hydroforming and equipment technology, applied in the direction of mechanical equipment, fluid pressure converters, etc., can solve the problems of high power consumption, insensitive control of speed and start and stop, and affect the processing quality of pipe fittings, so as to ensure the quality of the liquid output Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

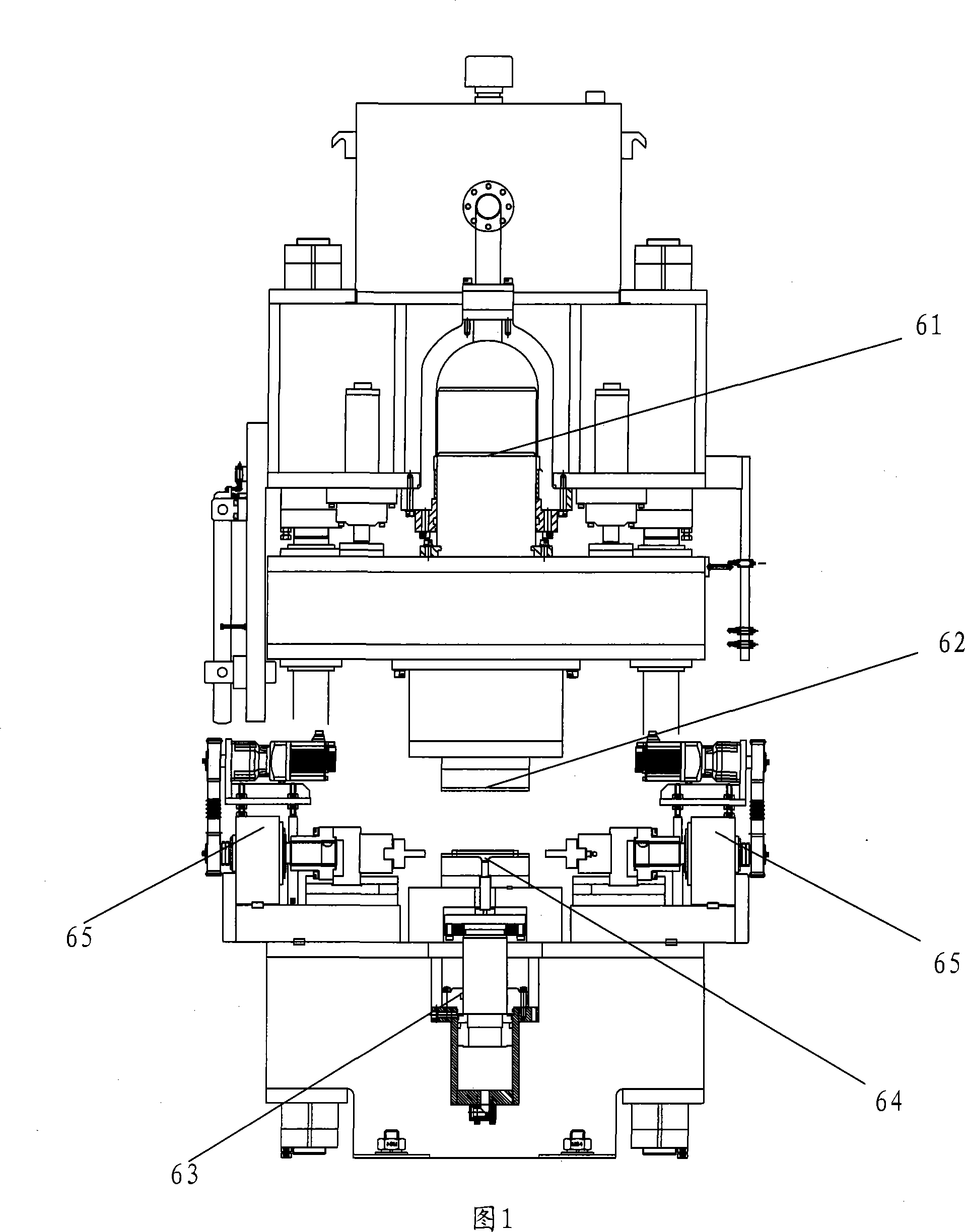

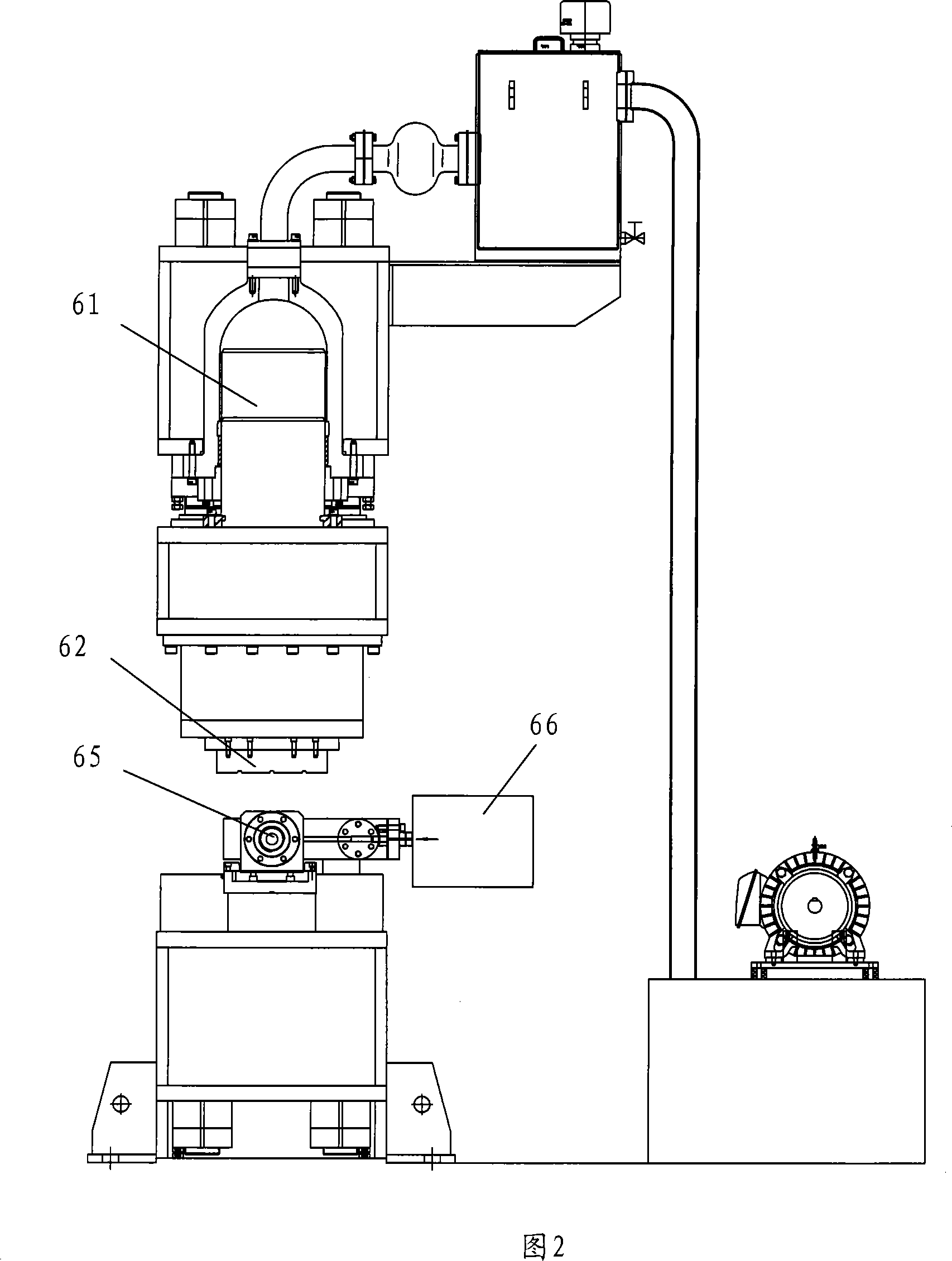

[0025] A hydroforming equipment, comprising a main pressure cylinder 61, a forming mold 62 arranged below the main pressure cylinder 61, a separate jacking cylinder 63 arranged below the forming mold 62, a workbench 64 arranged above the jacking cylinder 63, The thrust device 65 that is arranged on the two sides of workbench 64, is used for the supercharging device 66 that supplies liquid to workpiece, and supercharging device 66 comprises the supercharging mechanism 2 that is used for pressurizing low-pressure liquid to high-pressure liquid, is used for The driving mechanism 1 powered by the supercharging mechanism 2;

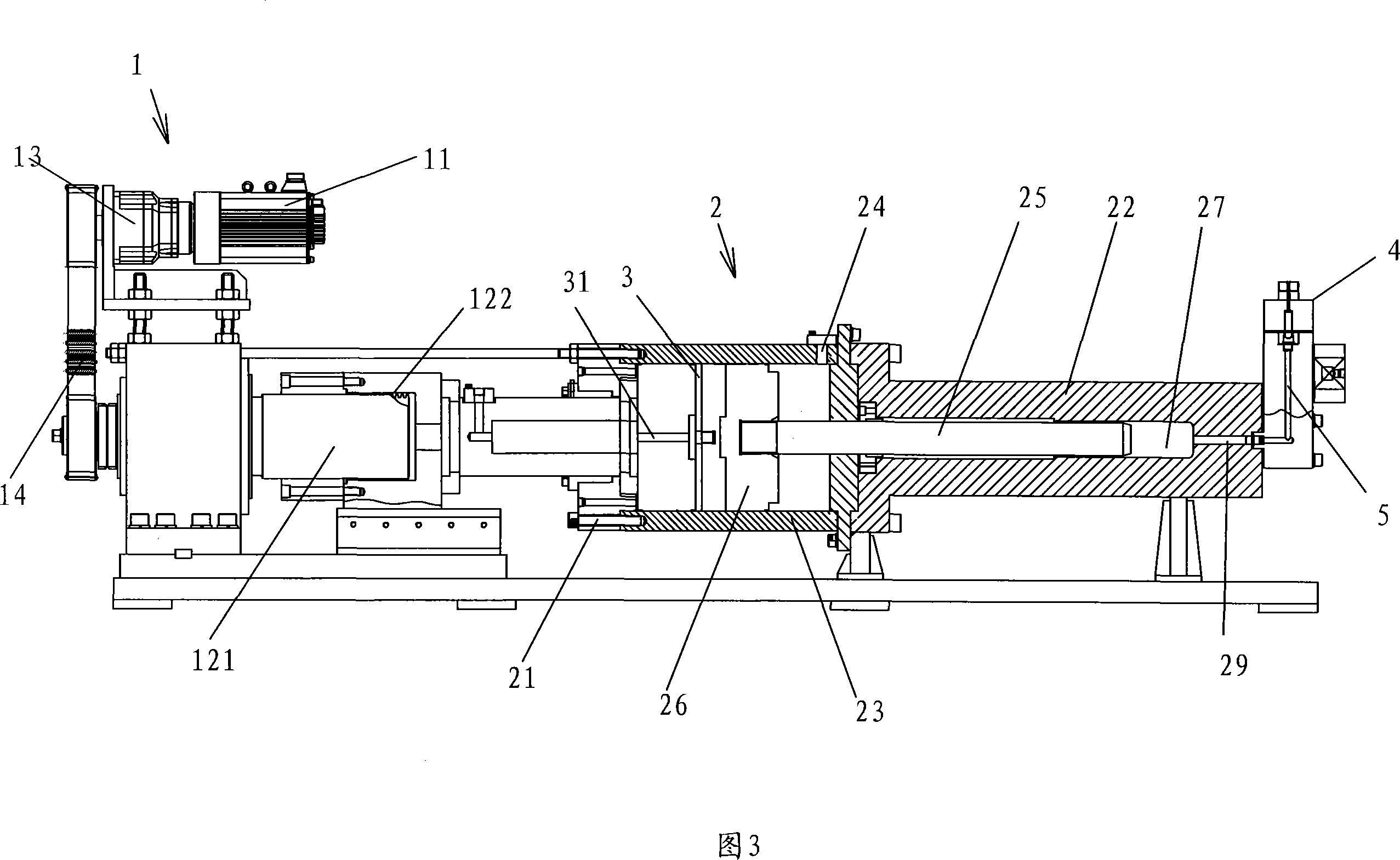

[0026] The supercharging mechanism 2 includes a first cylinder 22, a first piston 25 with one end slidably inserted inside the first cylinder 22, the first piston 25 is airtightly connected with the inner wall of the first cylinder 22, and the first piston 25 and part of the inner wall of the first cylinder to form a liquid storage chamber 27, the first cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com