Driver box body structure

A box structure and driver technology, which is applied in the direction of electric components, casings/covers/supports, electrical components, etc., can solve the problems of many parts of the push rod driver, insufficient self-locking function of the driver, hidden dangers of rotor bearing movement, etc. Achieve the effect of preventing axial movement, ingenious design, and reducing assembly processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

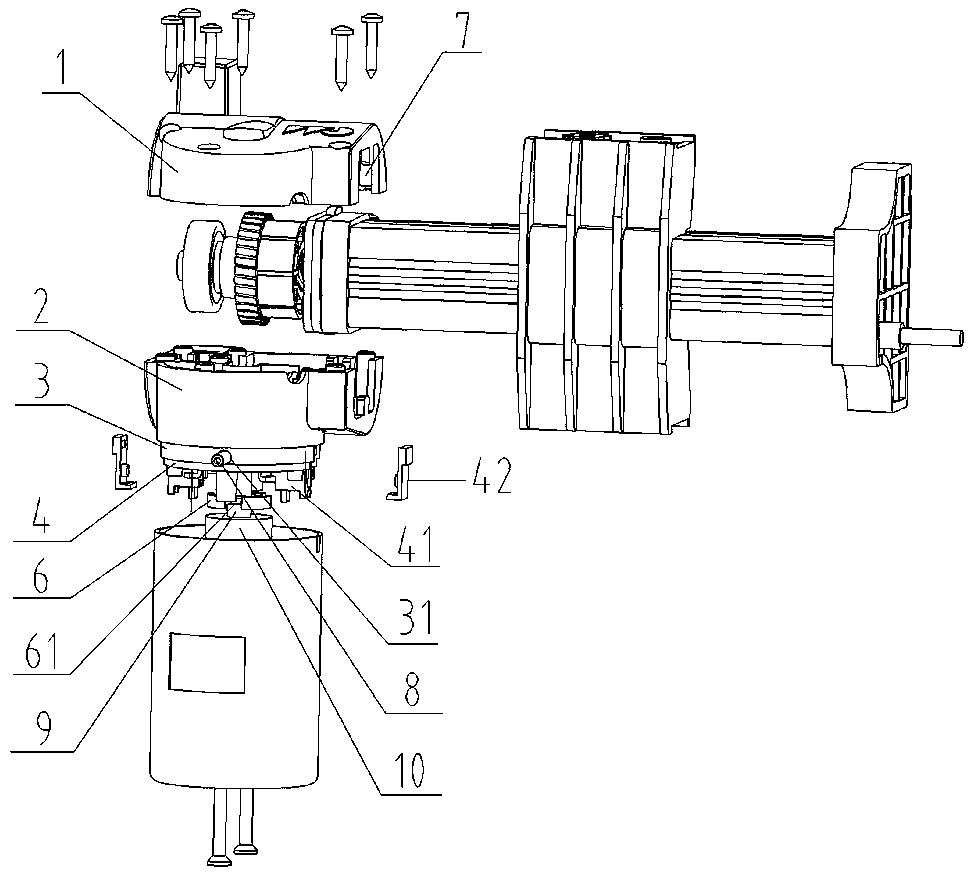

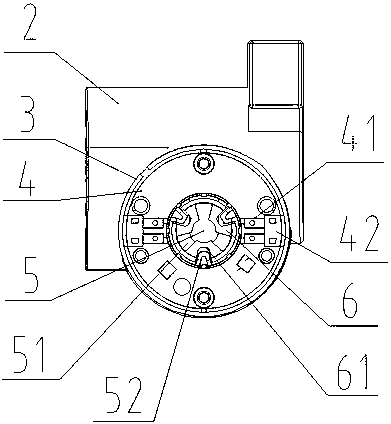

[0022] Below in conjunction with accompanying drawing, the present invention will be further described:

[0023] Such as figure 1 and figure 2 As shown, a driver box structure of the present invention includes an upper driver box 1 , a lower driver box 2 , a motor front cover 3 , a motor brush holder plate 4 and a damping member 6 . The motor front cover 3 is arranged on the lower box body 2 of the driver. The motor front cover 3 is provided with a motor brush holder plate 4, and two screw holes 31 are provided symmetrically on the side. Two brush holders 41 are symmetrically arranged on the motor brush holder plate 4 , and a through hole 5 is arranged in the center. The front and rear ends of the brush holder 41 are open and connected to each other. The brush holder plug 42 cooperates with the brush holder 41 and is detachably connected with the brush holder 41 . A limiting step 51 is arranged in the through hole 5 , and three bosses 52 are arranged on the limiting step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com