A kind of shuttle for mining trolley

A trolley, mining technology, applied in the direction of the clockwork mechanism, hoisting device, etc., can solve the problems of force transmission shuttle, danger, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

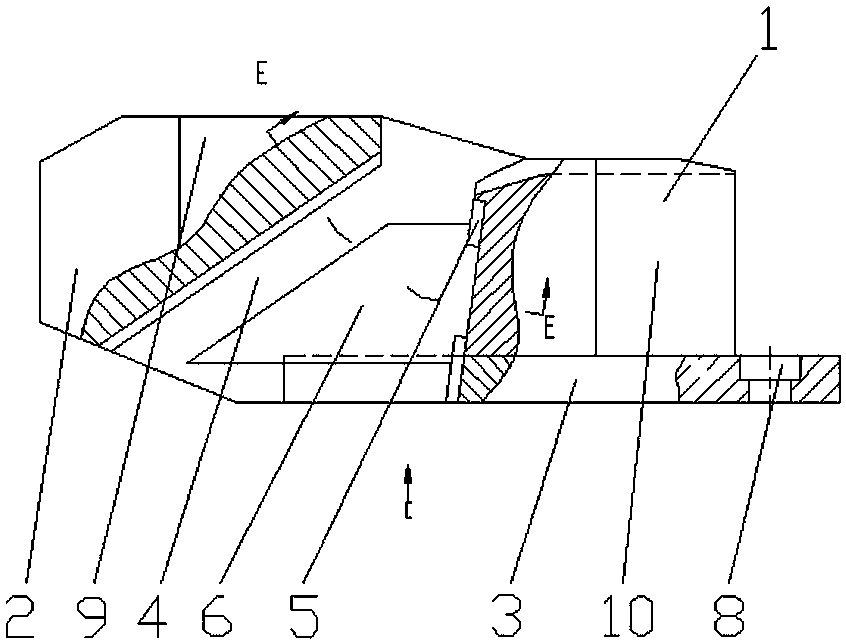

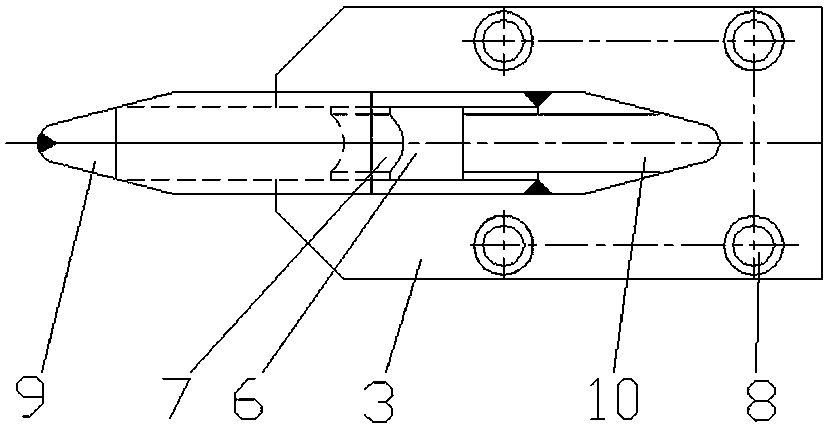

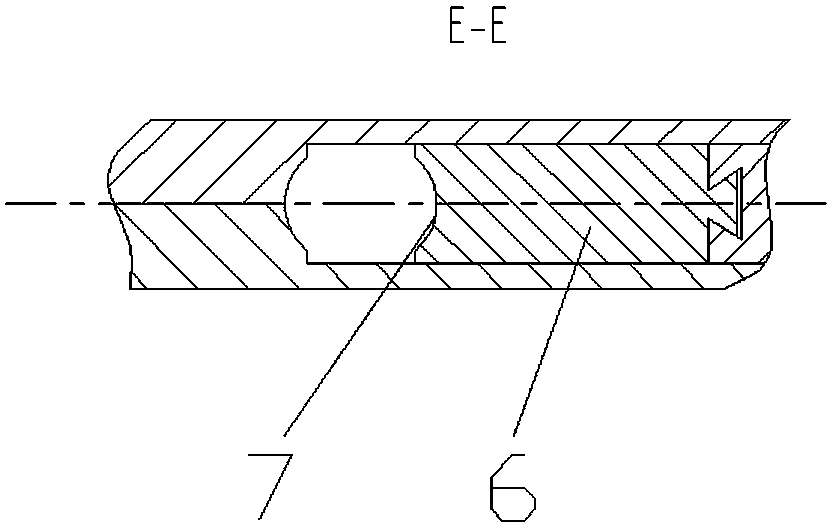

[0016] Such as Figure 1 to Figure 4 As shown, a shuttle for a mining trolley includes a body 1, the body 1 includes a touch plate 2 and a bottom plate 3, the touch plate 2 is vertically fixed on the bottom plate 3 so that the body 1 is in a "T" shape, and the touch plate 2 The left and right ends are pointed arcs, which are convenient for knocking open the rope wheel so that the trolley can pass safely. There is a transparent rope threading groove 4 in the middle of the body 1. The rope threading groove 4 gradually becomes smaller from the bottom plate 3 to the opening of the touch plate 2. Wedge-shaped structure, the wedge-shaped structure is a transparent square groove structure that gradually becomes smaller from the opening of the bottom plate, and the rope-threading groove 4 has a groove 5 on one side of the groove along the direction of the arc tip of the touch plate 2 and The end of the groove 5 close to the bottom plate 3 is an open end and the other end of the groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com