Reversible bucket

A technology of flipping buckets and buckets, which is applied in the directions of manipulators, transportation and packaging, loading/unloading, etc. It can solve the problems that robots cannot complete riot tasks, the size limit of manipulators, and obstacles that affect robots, so as to increase the discharge range. , increase the self-locking function, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

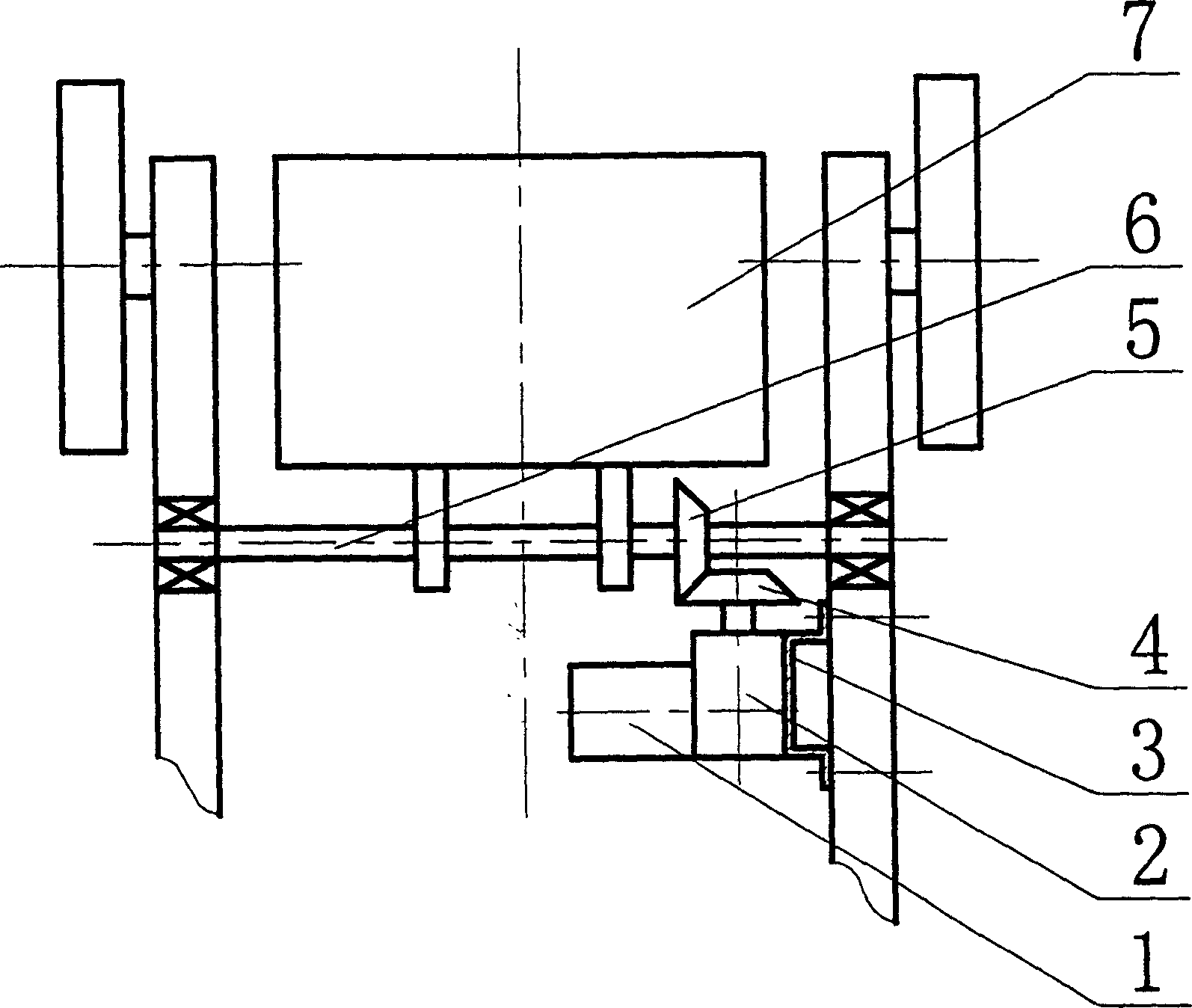

[0010] Such as figure 1 As shown, the present invention includes: a motor 1, a worm gear reducer 2, a reducer mounting seat 3, a bevel gear A4, a bevel gear B5, a rotating shaft 6, and a bucket 7. The connection method is: the reducer mounting base 3 is fixed on the robot swing arm, the worm gear reducer 2 is set on the reducer mounting base 3, the motor 1 is connected with the worm gear reducer 2, and the bevel gear A4 is fixed on the worm gear reducer On the output shaft of 2, the bevel gear B5 meshes with the bevel gear A4, the bevel gear B5 is fixed on the rotating shaft 6, the two ends of the rotating shaft 6 are connected with the swing arm of the robot by means of bearings, and the bucket 7 is fixed on the rotating shaft 6.

[0011] The torque output by the motor 1 is transmitted to the bevel gear A4 through the worm gear reducer 2, and then the torque is transmitted to the rotating shaft 6 through the meshing of the bevel gear A4 and the bevel gear B5, thereby driving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com