Structurally Improved Skid

A skid and positioning pin technology, which is applied to mechanical conveyors, transportation and packaging, conveyors, etc., can solve the problems of overturning, easy shaking of the body, and large amount of shaking of the body, so as to improve the safety factor and avoid the hidden danger of overturning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

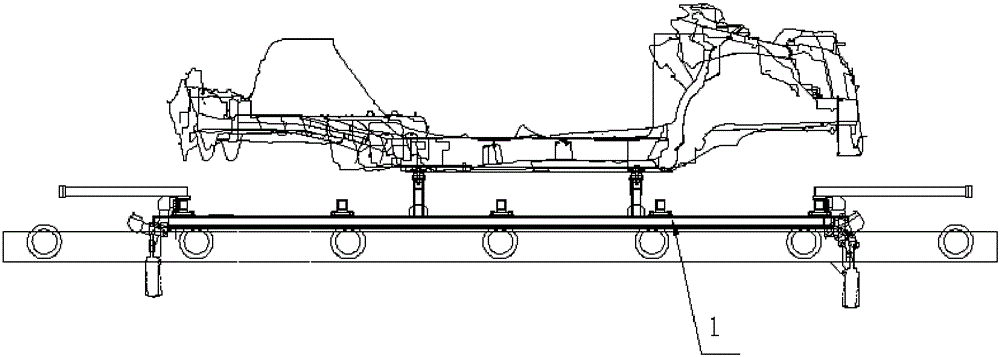

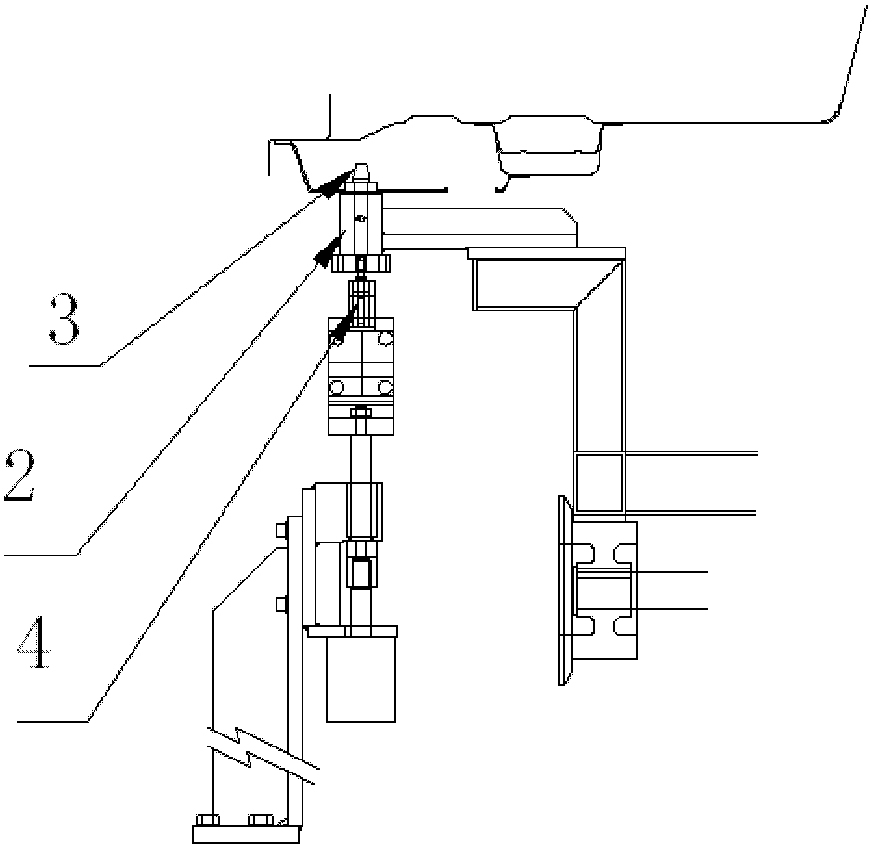

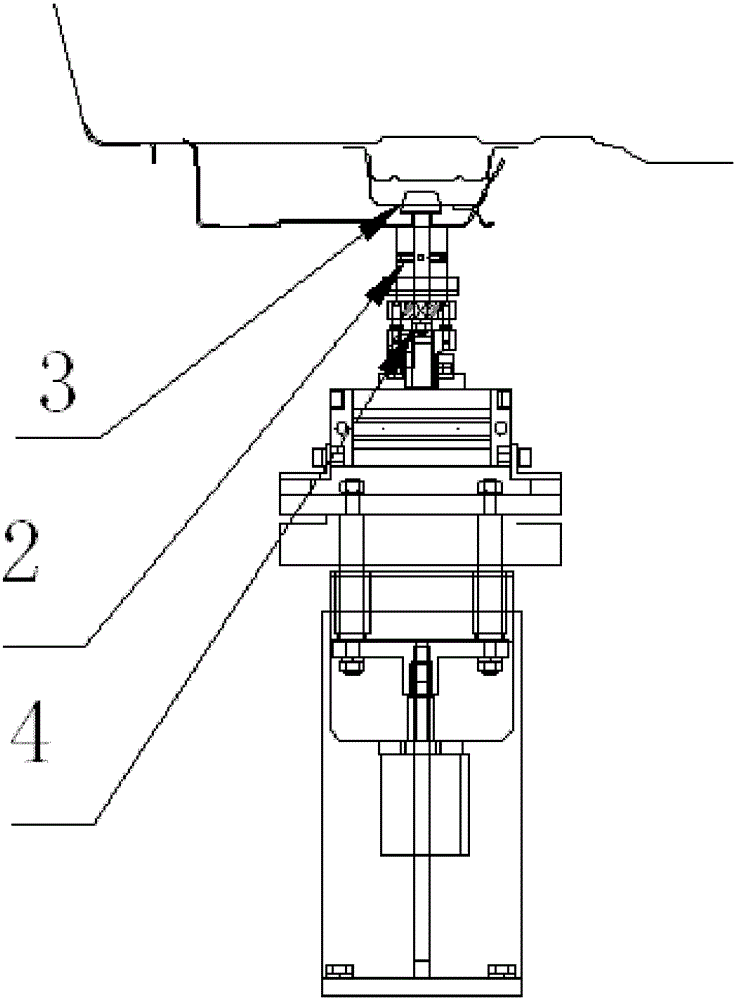

[0012] Embodiment: a kind of structurally improved skid comprises a skid body 1 and a positioning pin device, the positioning pin device is positioned on the skid body 1, and the positioning pin device comprises a shaft sleeve 2, a positioning pin 3 and a rotating power device 4, and the shaft The sleeve 2 is fixed on the pry body 1, and the positioning pin 3 can be rotated and inserted in the sleeve 2 in the circumferential direction. The upper end of the positioning pin 3 is provided with a radially outwardly expanded head in the shape of a strip, and the rotating power device 4 can drive the positioning. The pin 3 rotates, and the structure that the rotating power device 4 can drive the positioning pin 3 to rotate is: the lower end of the positioning pin 3 is provided with an inner groove, and the upper end of the power output part of the rotating power device 4 is provided with a protrusion, which can just extend Enter into the inner groove of the lower end of the positioni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com