Support regulating device and assembling tool

A technology for adjusting devices and supporting components, applied in workpiece clamping devices, manufacturing tools, hand-held tools, etc., can solve the problems of unadjustable support height and workpiece surface wear, etc., and achieve easy change, long service life, and avoid shrinkage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

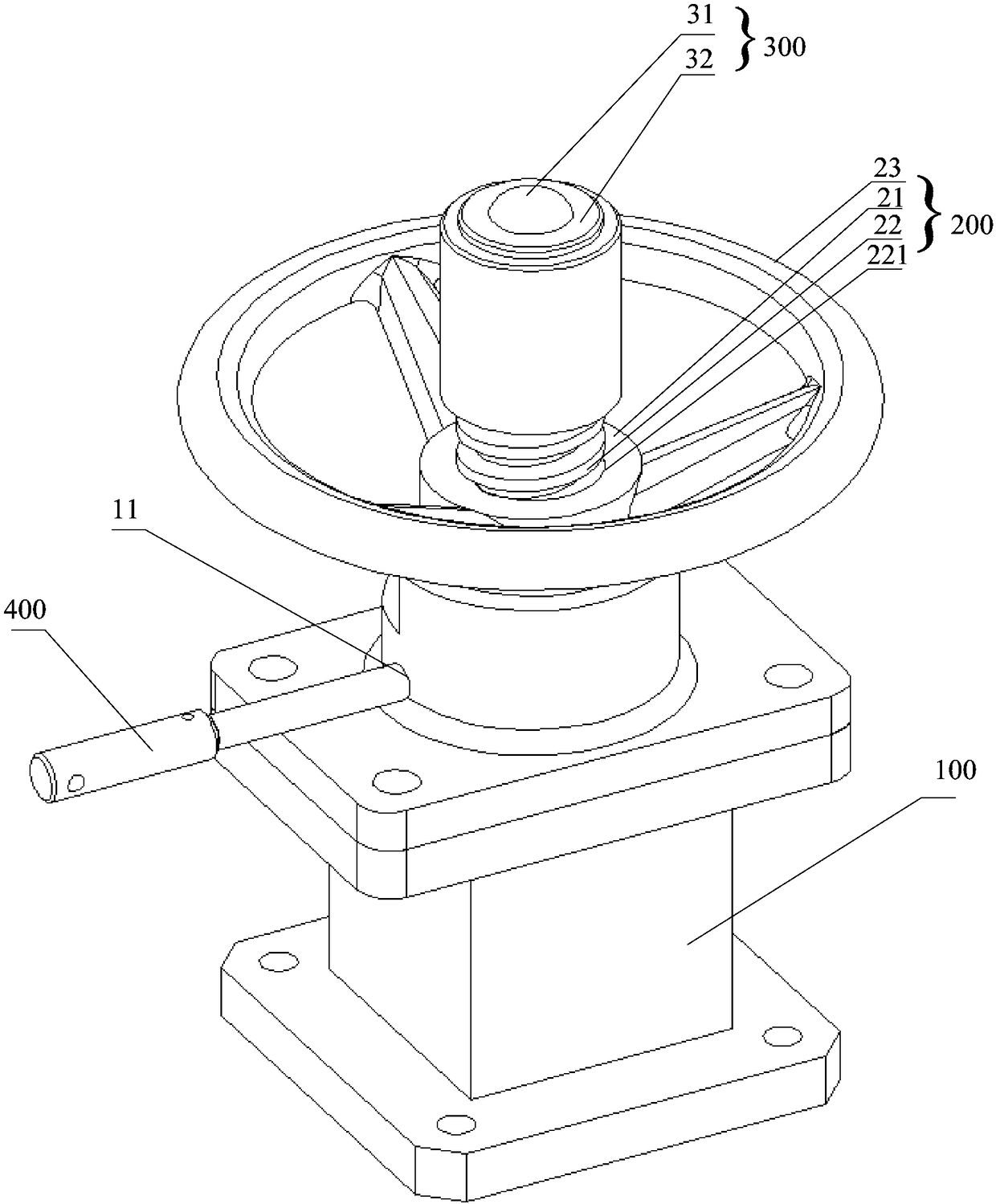

[0043] figure 1 For the structural schematic diagram of the support adjustment device provided by the embodiment of the present invention, refer to figure 1 As shown, one aspect of the present invention provides a support adjustment device, including a base 100, a height adjustment assembly 200 and a top support assembly 300 connected in sequence;

[0044] The top of the top support assembly 300 is provided with a universal ball 31;

[0045] The height adjustment assembly 200 includes a lead screw 21 and a connecting piece 22 threaded with the leading screw 21. The connecting piece 22 is located on the base 100, and the leading screw 21 is connected to the top support device 300. The leading screw 21 can be relative to the connecting piece 22 around its own axis. Rotate to drive the top supporting assembly 300 to expand and contract relative to the base 100 .

[0046] Specifically, the working principle of the support adjustment device is that the lead screw 21 rotates relat...

Embodiment 2

[0052] continue to refer figure 1 As shown, in the support adjustment device provided in this embodiment, a plurality of positioning holes (not shown in the figure) are arranged in the axial direction on the lead screw 21, and the support adjustment device also includes a locking member 400 connected with the connecting member 22, and the locking One of the fasteners 400 can be inserted into the positioning hole.

[0053] Specifically, the locking member 400 is a strip-shaped handle structure. By inserting the locking member 400 into the positioning hole on the lead screw 21, the lead screw 21 can be locked so that the lead screw 21 cannot be stretched, that is, the entire support adjustment The support height of the device is fixed.

[0054] A plurality of positioning holes can be set on the leading screw 21, and the specific positions of the positioning holes are determined according to the height to be locked. There are multiple heights that need to be positioned when the ...

Embodiment 3

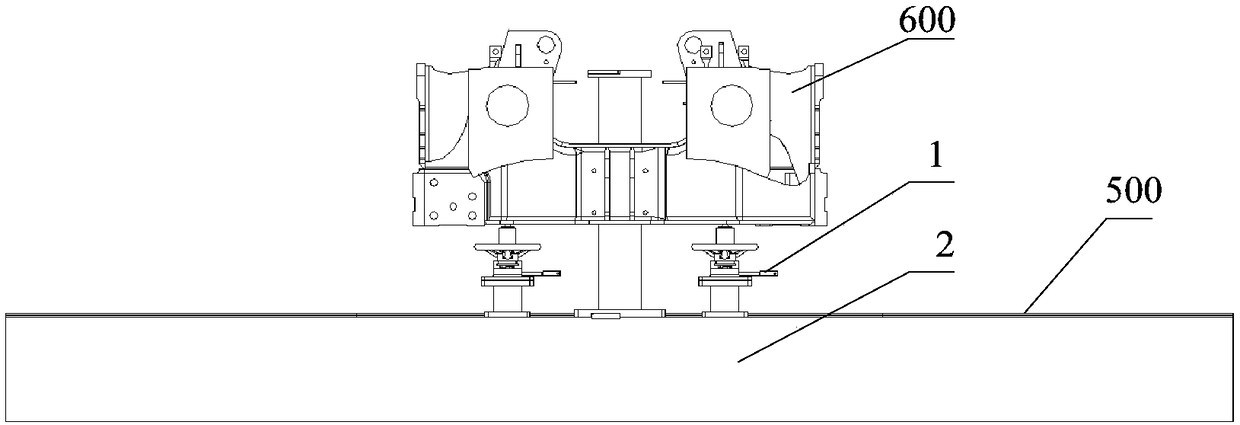

[0069] figure 2 For the structural schematic diagram of the assembly tool provided by the embodiment of the present invention, refer to figure 2 As shown, the embodiment of the present invention provides an assembly tool 2, including a tool platform 500 and a plurality of support adjustment devices 1 as above;

[0070] In this embodiment, the base 100 is detachably connected to the tooling platform 500 . When the support adjustment device 1 supports the workpiece 6006, it is generally placed on the tooling platform 500. Due to the differences in the supported workpieces 600, the number of support adjustment devices 1 required and the location of the support adjustment device 1 are also different. In order to facilitate changing the support The number and position of the adjusting device 1 can be determined by setting mounting holes on the base 100 supporting the adjusting device 1 , and the base 100 is detachably connected to the tooling platform 500 . Optionally, the base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com