Pressing treatment device for material machining and method

A processing device and material processing technology, applied in the field of lamination processing, can solve problems such as material breakage, and achieve the effect of increasing pressure, improving precision and material running speed, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

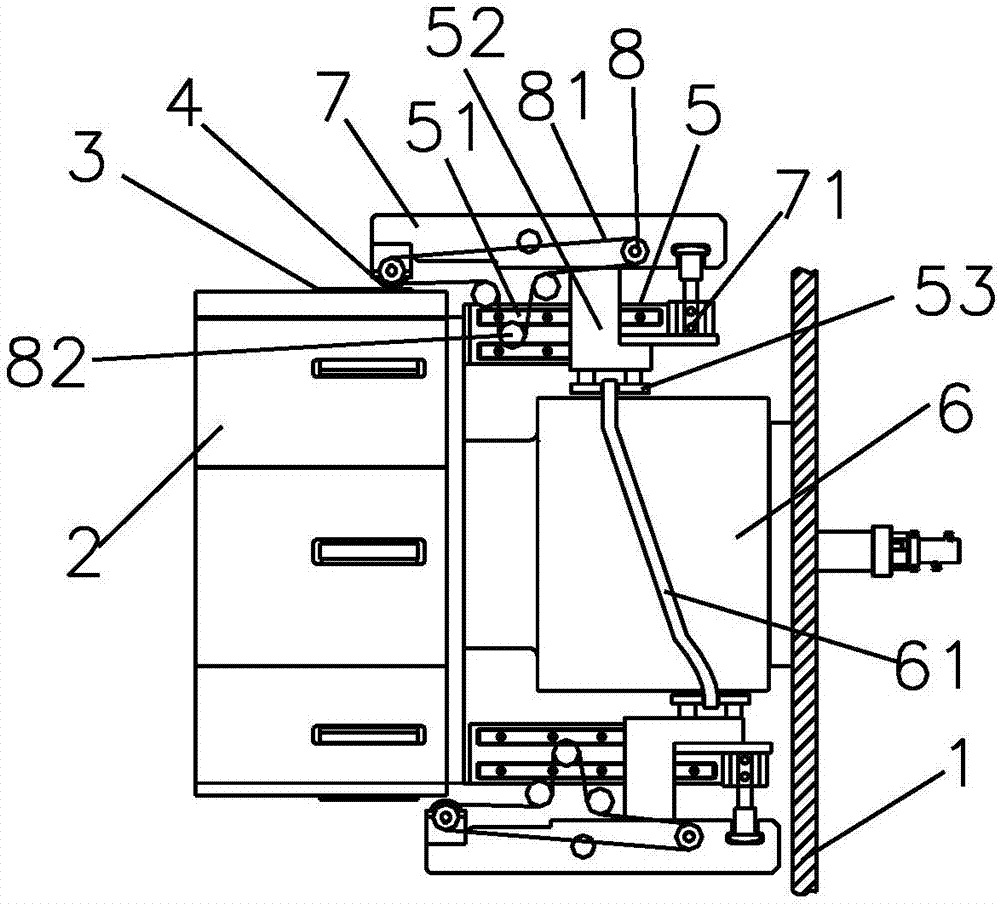

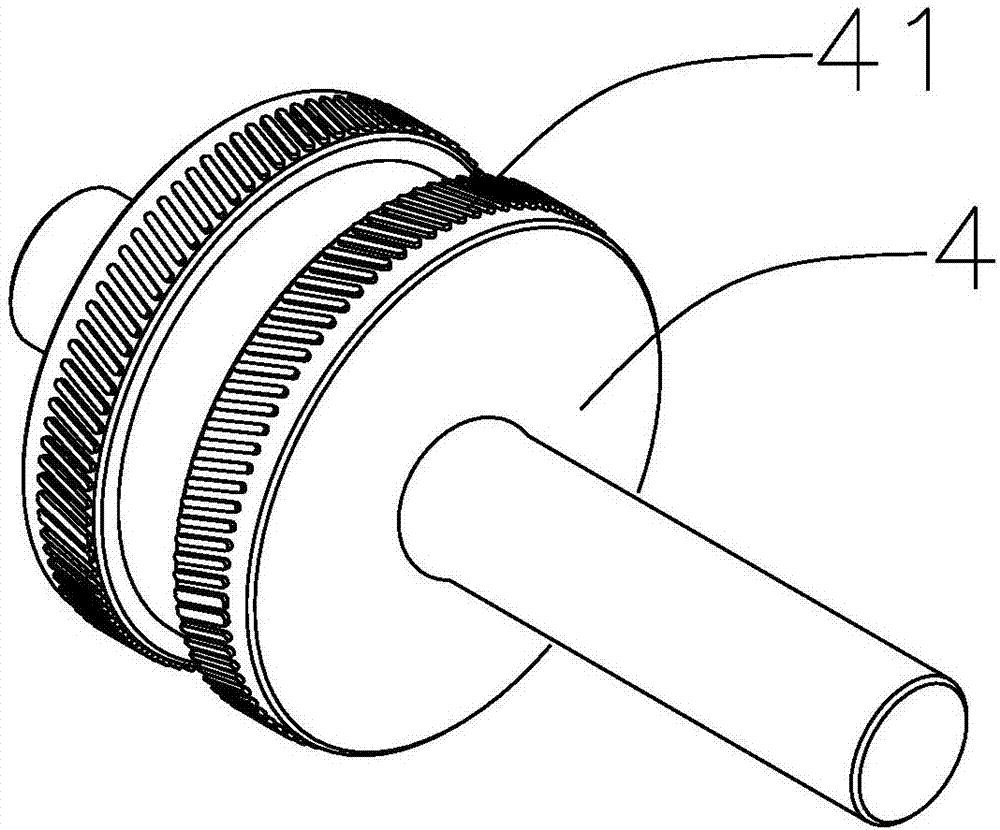

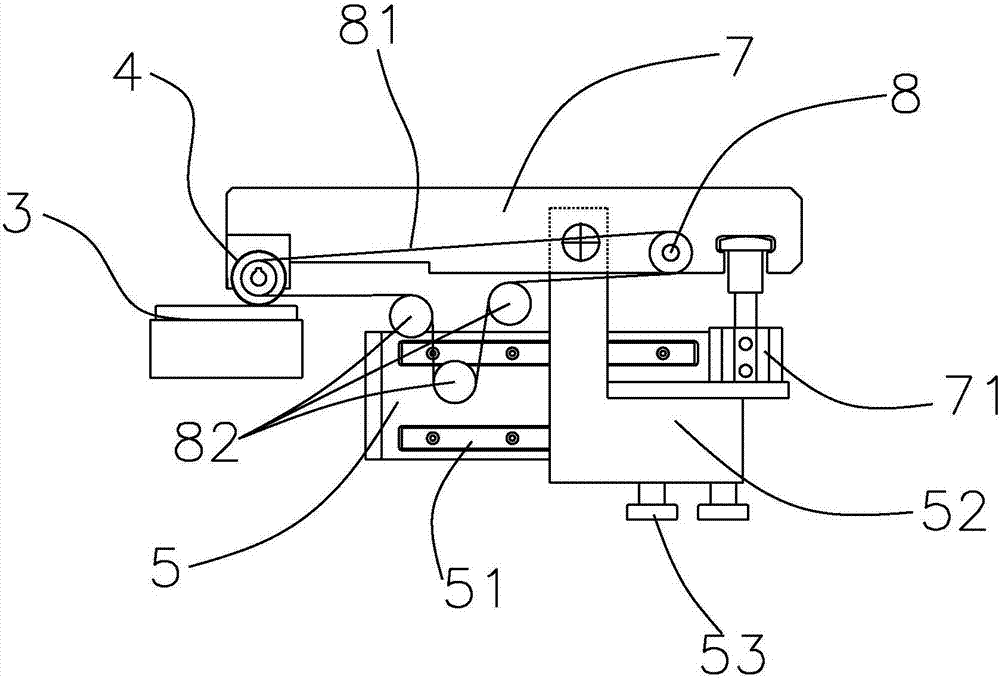

[0022] Such as figure 1 As shown, a pressing processing device for material processing includes a rotating disk 2 and several pressing welding assemblies, the rotating disk 2 is installed on the panel 1 and driven by a motor, and the outer peripheral surface of the rotating disk 2 A walking path is provided, and the pressing assembly includes a pressing welding head 3 arranged inside the walking path, a pressing mold roller 4 arranged outside the walking path, a pushing mechanism, a lifting mechanism and a rolling drive mechanism, and the lifting The mechanism drives the pressing mold roller 4 away from or close to the pressing welding head 3, the pushing mechanism drives the pressing mold roller to reciprocate radially along the rotating disk 2, and the rolling driving mechanism drives the Describe the rotation of pressing mold cylinder 4, as figure 2 As shown, the pressing mold drum 4 includes a main body of the drum and a mold pattern 41 arranged on the peripheral surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com