Hydraulic control system of balance cylinders in hydrostatic test

A technology of hydraulic control system and balancing cylinder, which is applied in the direction of applying stable tension/pressure to test material strength, fluid pressure actuating device, servo motor, etc. , sealing failure and other problems, to achieve the effect of reducing the action area, the operation process is simple and fast, and reducing the pre-sealing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Typical embodiments embodying the features and advantages of the present invention will be described in detail in the following description. It should be understood that the present invention is capable of various changes in different embodiments without departing from the scope of the present invention, and that the description and drawings therein are illustrative in nature and not limiting. this invention.

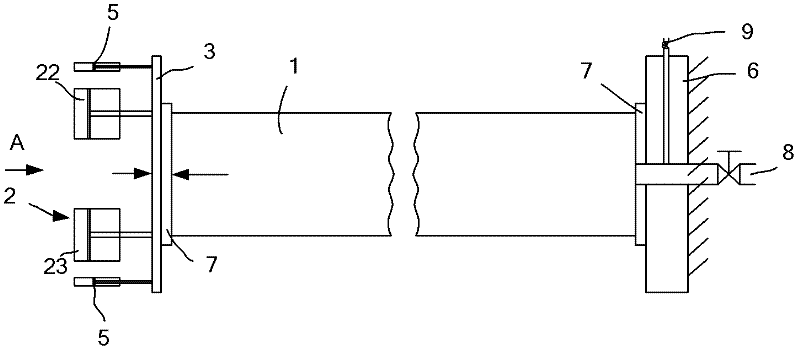

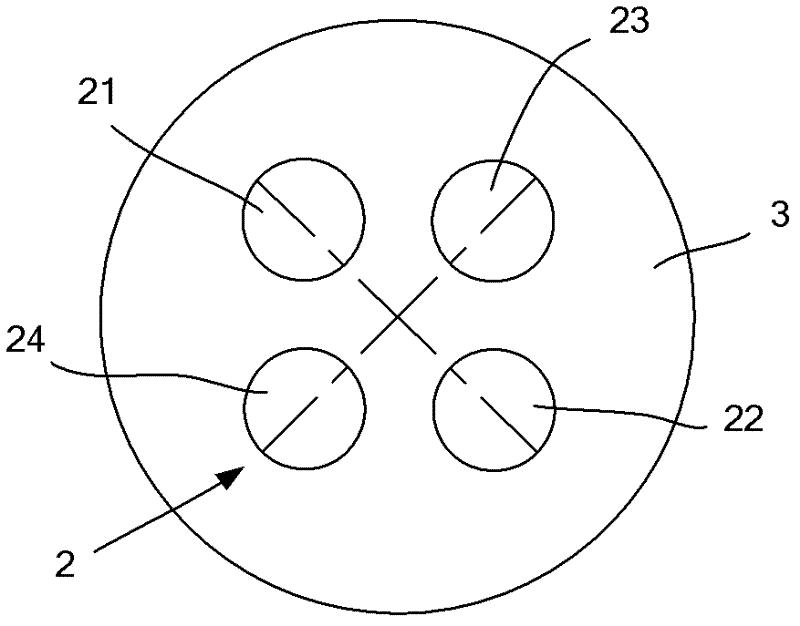

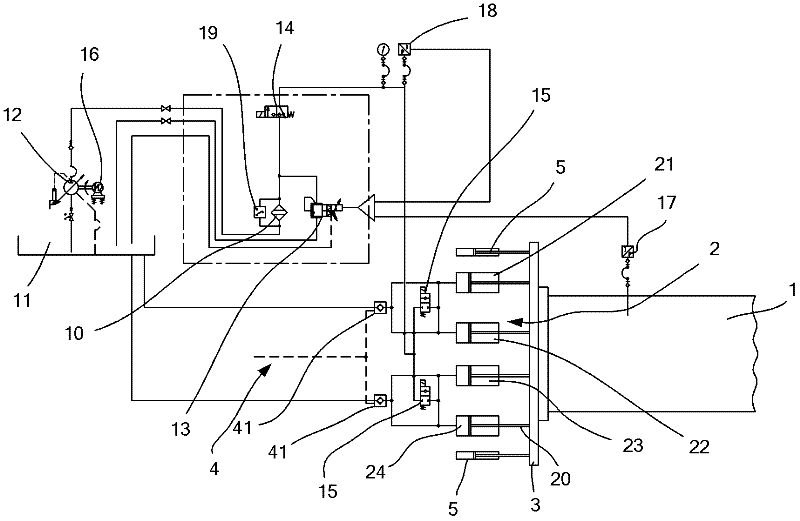

[0025] In the present invention, each structure of the welded pipe 1 is the same as that in the prior art when carrying out the hydrostatic pressure test, such as figure 1 As shown, and has been described in detail in the background technology, and will not be repeated here. figure 2 The distribution state of each balance cylinder 2 in this embodiment is shown. There are four balance cylinders 21, 22, 23 and 24 in this embodiment, and the four balance cylinders 21, 22, 23, 24 form an annular array, and the 1 The axis extension line is the center line.

[0026...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com