Stirring device for building operation

A mixing device and building construction technology, applied in cement mixing devices, clay preparation devices, chemical instruments and methods, etc., can solve problems such as high noise, reduce noise, increase mixing effect, and reduce the effect of area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

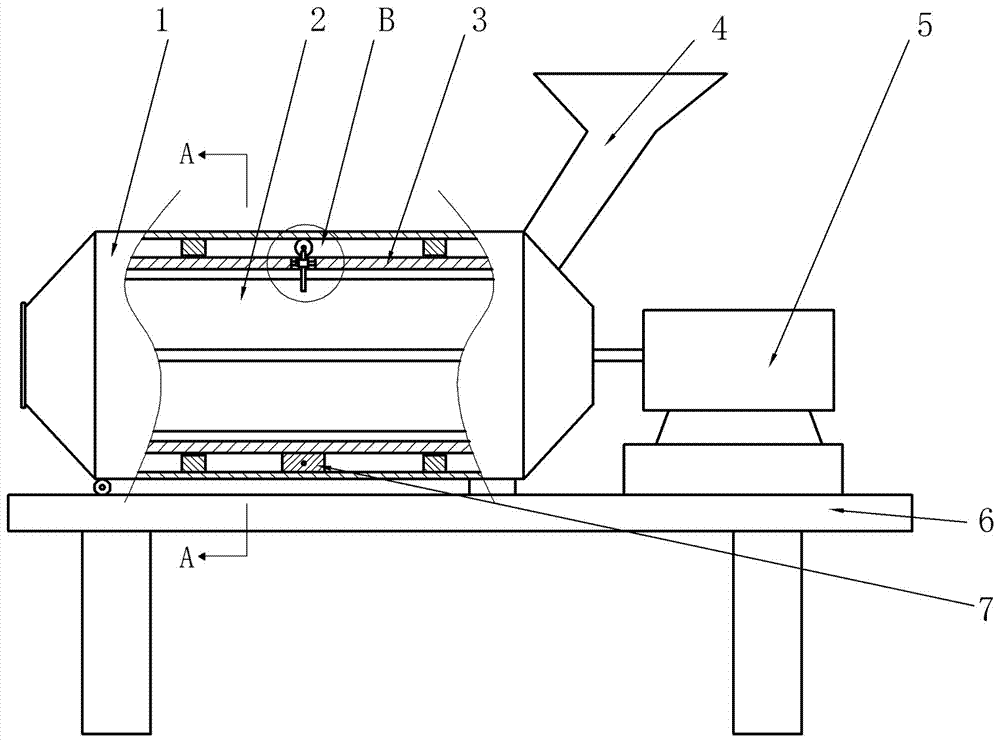

[0019] Embodiment: the building construction mixing device in this scheme, as figure 1 As shown, the outer cylinder 1 is cylindrical with one end closed, the front pin hole of the outer cylinder 1 is hinged on the fixed platform 6, and the lower rear end of the outer cylinder 1 is threadedly connected with a pad made of rubber. The inner wall of the outer cylinder 1 is integrally formed with a guide ring, and the mixing drum 3 is rotatably connected in the guide ring. The drive motor 5 is screwed on the fixed table 6, the output end of the drive motor 5 extends into the mixing drum from the closed end of the cylinder, the stirring blade 2 is plate-shaped, and the three stirring blades 2 are evenly threaded on the output end of the drive motor 5. Circumferentially, there is a sieving gap for sieving larger stones between the stirring blade 2 and the inner wall of the mixing drum 3, and the size of the sieving gap is 12mm.

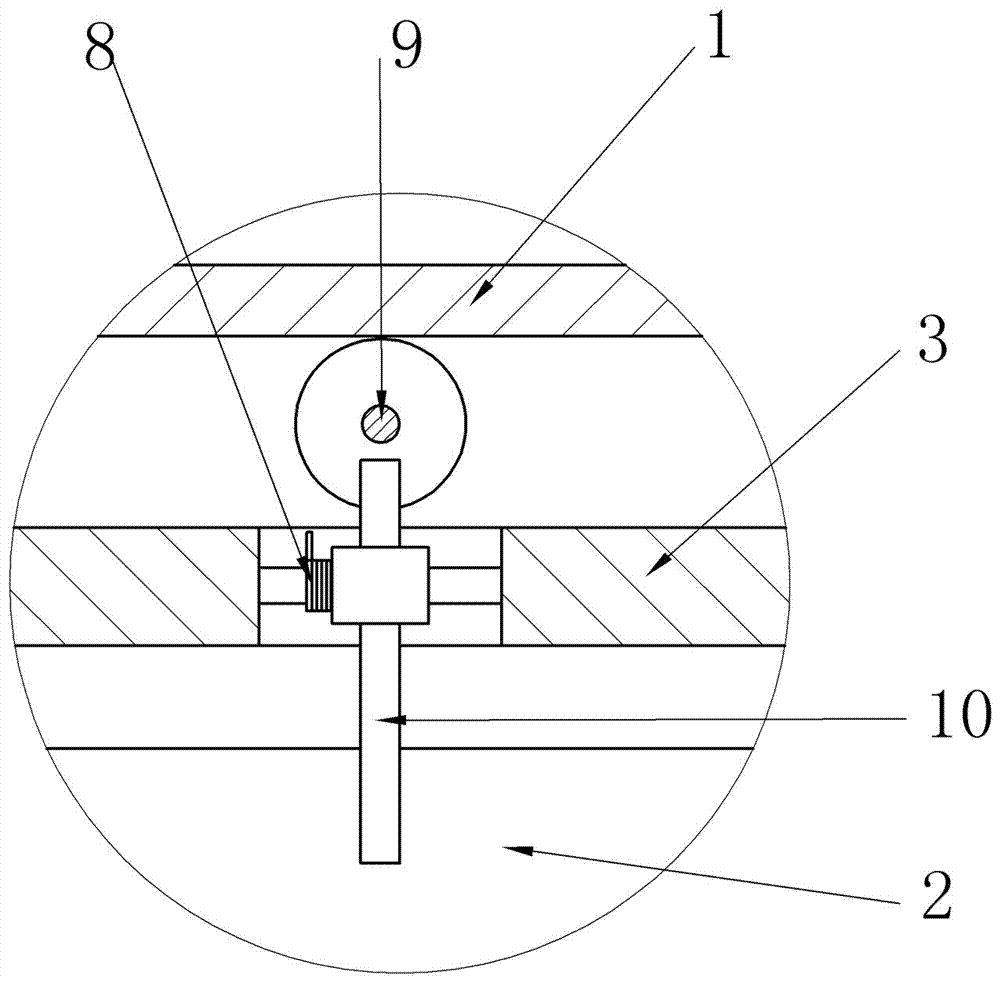

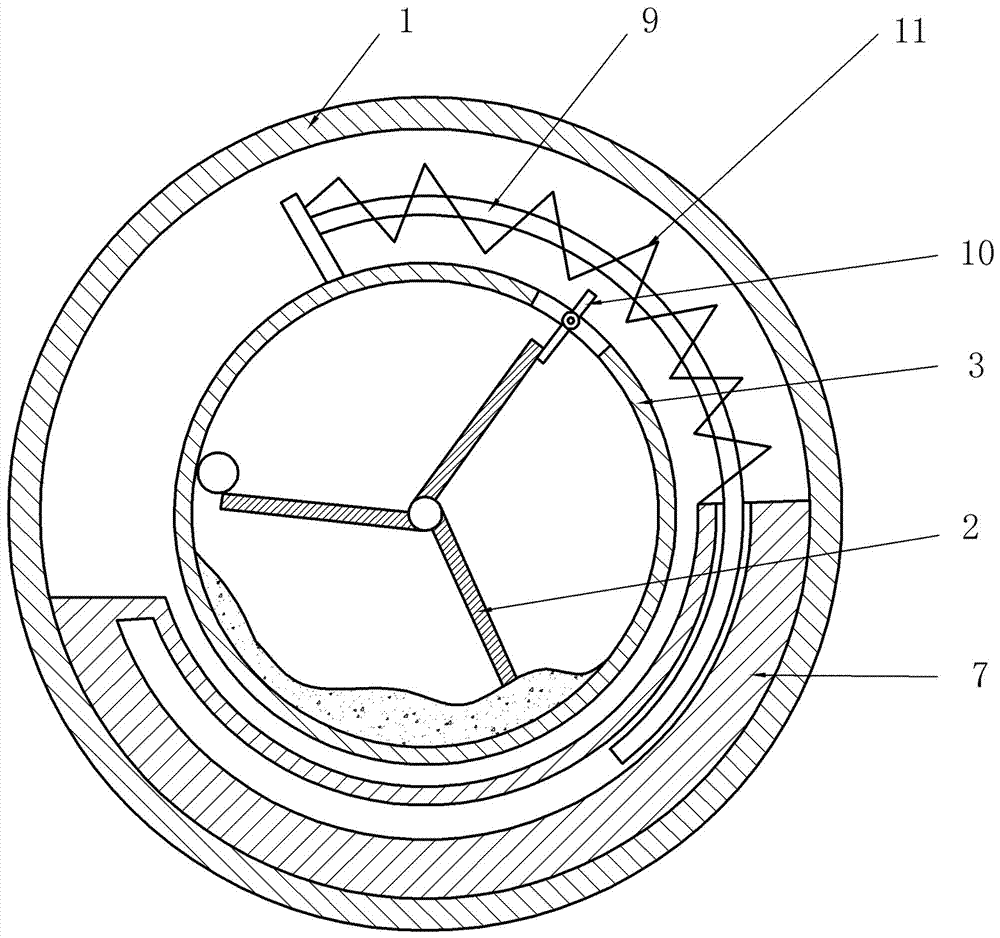

[0020] Such as figure 2 and image 3 As shown, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com