Chip type oxygen sensor structure and manufacturing method thereof

A technology of an oxygen sensor and a manufacturing method, which is applied to instruments, scientific instruments, measuring devices, etc., can solve problems such as twisting or twisting of sensitive components and failure of oxygen sensors, so as to improve sealing effect, improve product yield, and prevent relative the effect of rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

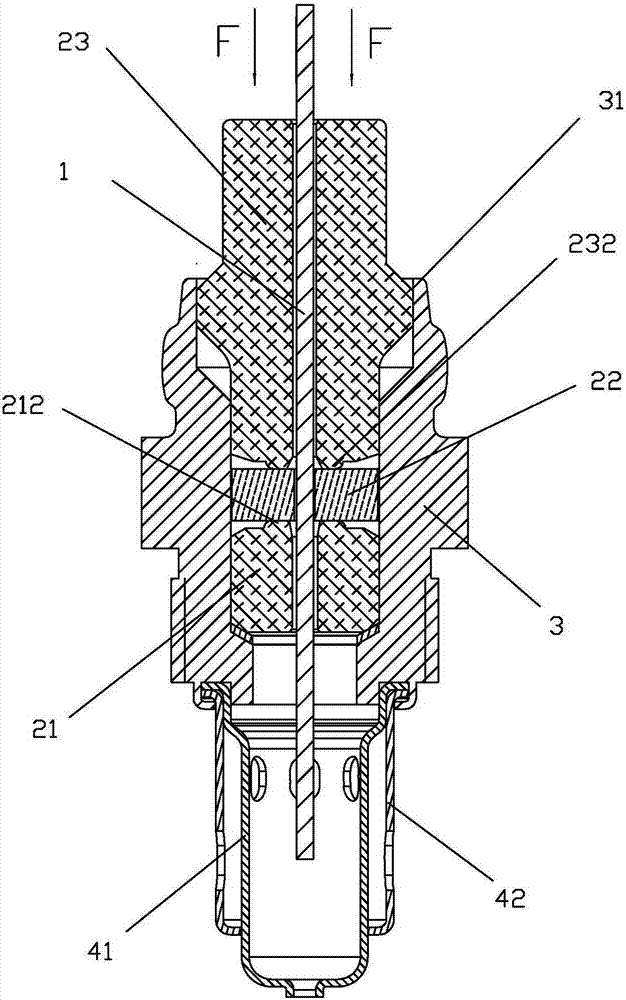

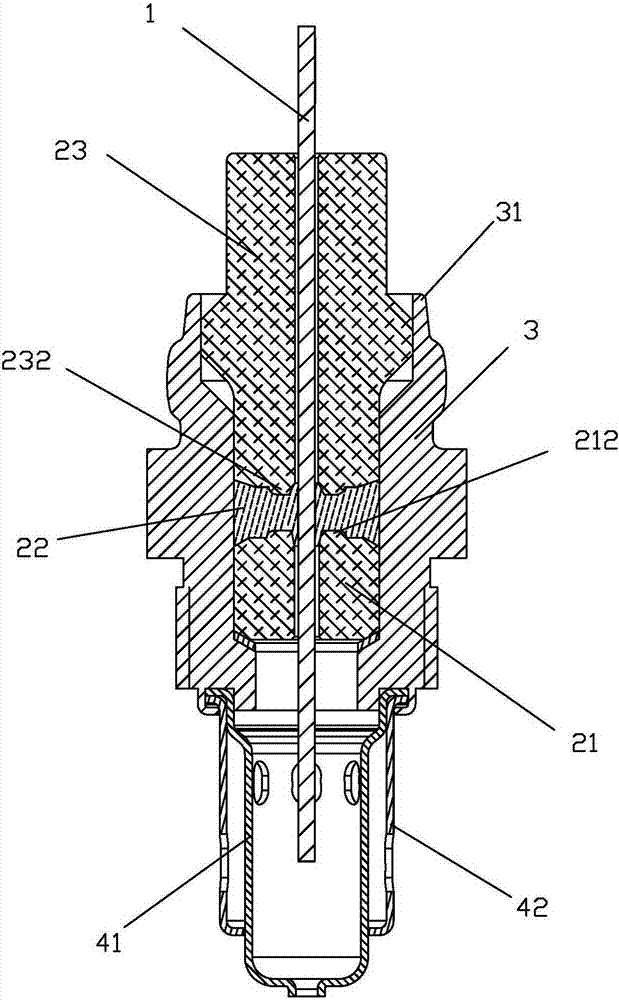

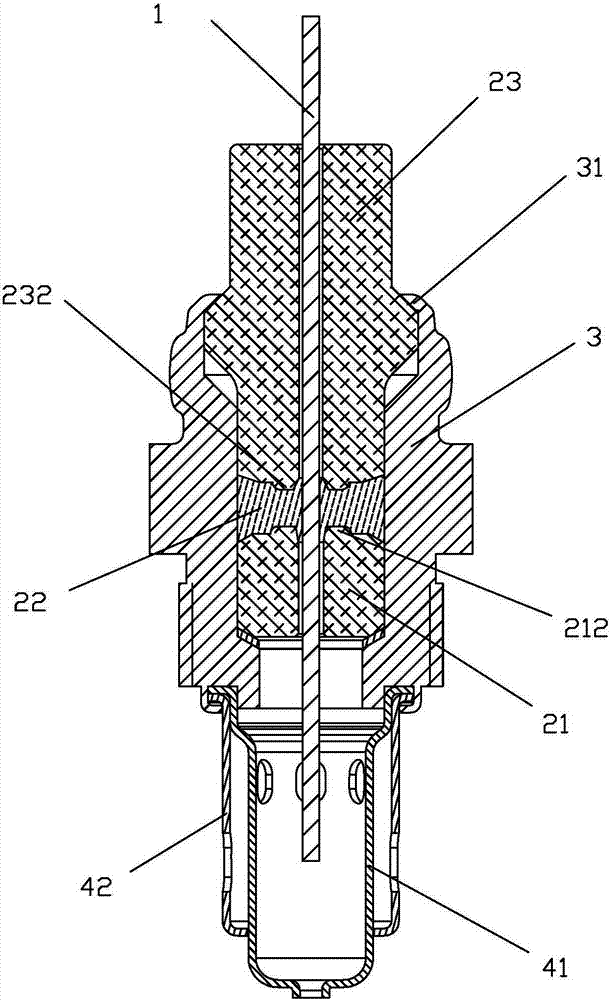

[0029] see Figure 1 to Figure 7 As shown, a chip oxygen sensor structure of the present invention includes a sensitive element 1, a sealing device and an installation housing 3; the sensitive element 1 is fixed in the installation housing 3 through the sealing device; the sealing device includes a front end ceramic Part 21, sealing ring 22 and rear end ceramic part 23; the sensitive element 1 is worn in the front end ceramic part 21, sealing ring 22 and rear end ceramic part 23 arranged in sequence, under the effect of preset pressure, the sealing ring 22 Fill the gap between the ceramic parts (i.e. the front end ceramic part 21, the rear end ceramic part 23), the installation housing 3 and the sensitive element 1 tightly, that is, the sealing ring 22 is filled in the ceramic parts (i.e. the front end ceramic part 21, the rear end ceramic part 21) end ceramic part 23), the installation shell 3 and the space surrounded by the sensitive element 1; in the front end ceramic part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com