Low-temperature nitriding-based vanadium nitride powder and preparation method thereof

A low-temperature nitriding and vanadium nitride technology, which is applied in the field of vanadium nitride powder, can solve the problems of increasing the production cost of vanadium nitride products, cumbersome preparation process, long holding time, etc., and achieves low cost, simple process and improved structure The effect of toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

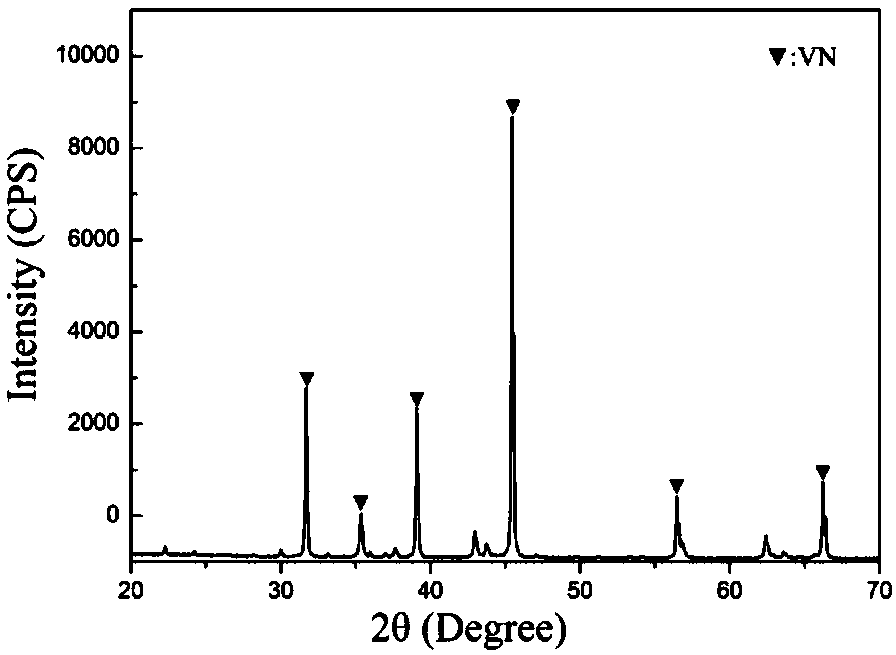

[0036] A vanadium nitride powder based on low-temperature nitriding and a preparation method thereof. The preparation method described in this embodiment is:

[0037] According to the mass ratio of aluminum powder: vanadium pentoxide powder: inorganic salt is 1: (0.2~0.025): (0.7~0.75), the aluminum powder, the described vanadium pentoxide powder and the inorganic salt Mix to obtain mixed powder.

[0038] The mixed powder is kept in a nitrogen atmosphere at 700-750° C. for 1-1.5 hours, and naturally cooled to obtain a fired product.

[0039] The burnt product is added into hydrochloric acid solution, soaked for 1-2 hours, washed with distilled water for 3-5 times, and dried at 90-110° C. for 8-12 hours to obtain vanadium nitride powder based on low-temperature nitriding.

Embodiment 2

[0042] A vanadium nitride powder based on low-temperature nitriding and a preparation method thereof. The preparation method described in this embodiment is:

[0043] According to the mass ratio of aluminum powder: vanadium pentoxide powder: inorganic salt is 1: (0.25~0.3): (0.75~0.8), the aluminum powder, the described vanadium pentoxide powder and the inorganic salt Mix to obtain mixed powder.

[0044] The mixed powder is kept in a nitrogen atmosphere at 750-800° C. for 1.5-2.0 hours, and naturally cooled to obtain a fired product.

[0045] The burnt product is added into hydrochloric acid solution, soaked for 1-2 hours, washed with distilled water for 3-5 times, and dried at 90-110° C. for 8-12 hours to obtain vanadium nitride powder based on low-temperature nitriding.

Embodiment 3

[0048] A vanadium nitride powder based on low-temperature nitriding and a preparation method thereof. The preparation method described in this embodiment is:

[0049] According to the mass ratio of aluminum powder: vanadium pentoxide powder: inorganic salt is 1: (0.3~0..35): (0.8~0..85), the aluminum powder, the described vanadium pentoxide powder The powder is mixed with the inorganic salt to obtain a mixed powder.

[0050] The mixed powder is kept in a nitrogen atmosphere at 800-850° C. for 2.0-2.5 hours, and naturally cooled to obtain a fired product.

[0051] The burnt product is added into hydrochloric acid solution, soaked for 1-2 hours, washed with distilled water for 3-5 times, and dried at 90-110° C. for 8-12 hours to obtain vanadium nitride powder based on low-temperature nitriding.

[0052] The inorganic salt is a mixture of sodium chloride and sodium fluoride.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com