Zinc alloy mold rapid manufacture process based on rapid prototyping and zinc alloy mold material

A manufacturing process and zinc alloy technology, applied in the field of mold manufacturing, can solve the problems of high energy consumption, poor fluidity, and high melting temperature, and achieve the effects of reducing manufacturing costs, shortening manufacturing time, and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

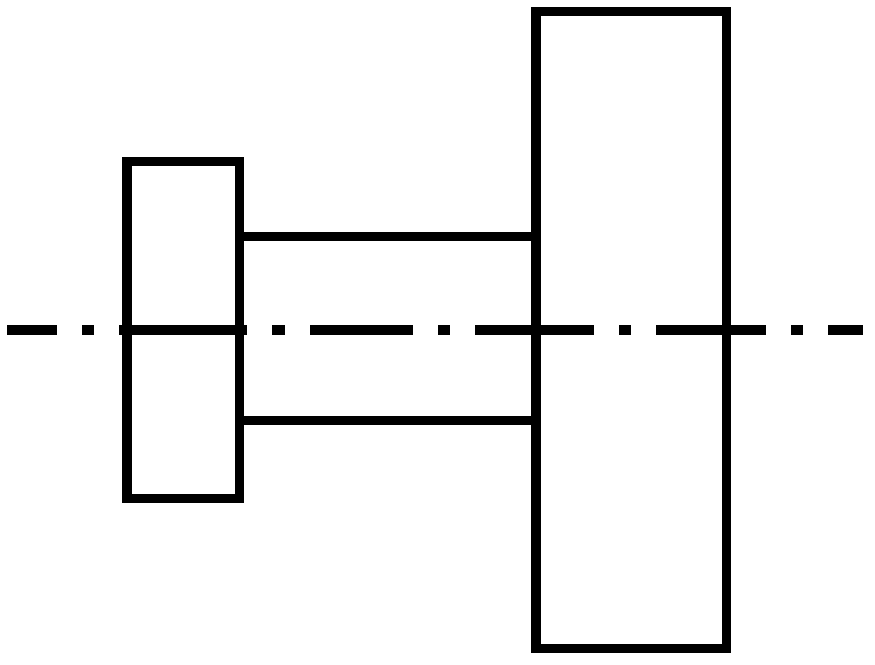

[0038] 1. If figure 1 As shown, if you want to quickly make a zinc alloy mold for a shaft part, first draw a three-dimensional CAD drawing in PRO / E or other CAD software, output it as an STL format file, and input it into the data processing software of the rapid prototyping machine for processing data Processing, making a rapid prototype in the rapid prototyping machine.

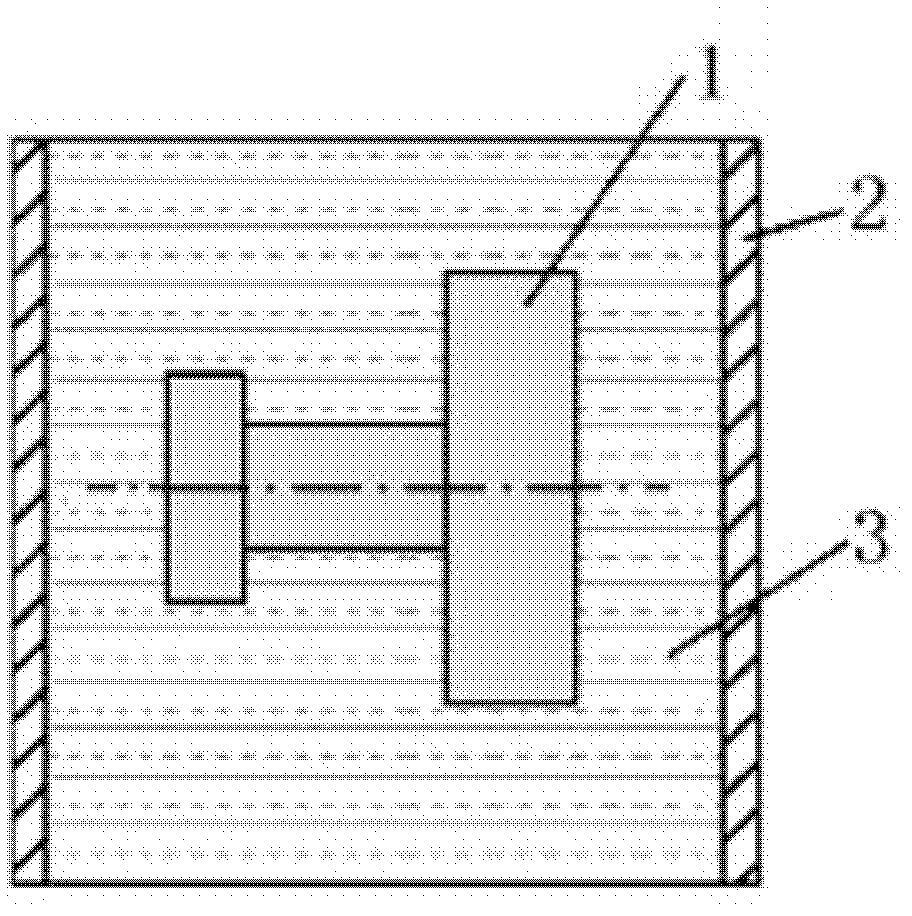

[0039] 2. If figure 2 As shown, the rapid prototype 1 is placed in the mold frame 2 and fixed, the degassed liquid silicone rubber and curing agent mixture 3 is injected into the mold frame, and the mold frame is removed after curing.

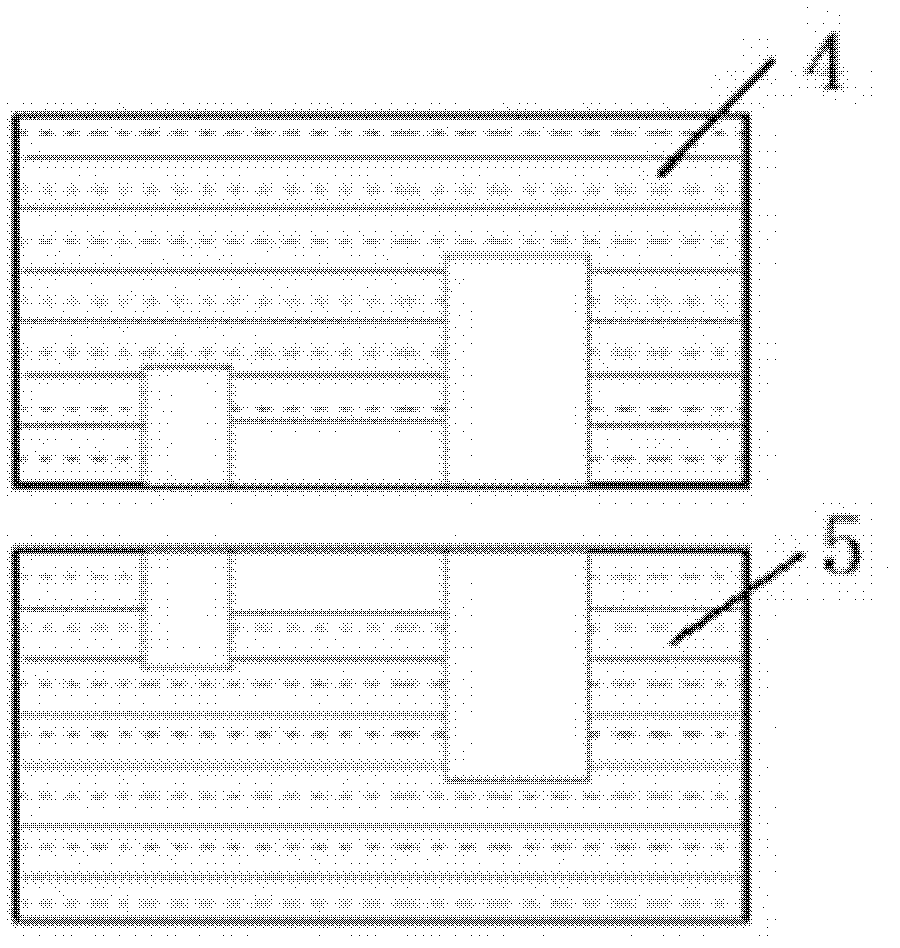

[0040] 3. If image 3 As shown, use a blade to cut the silicone rubber along the predetermined parting surface, remove the rapid prototype, and obtain the upper and lower mold halves 4 and 5 at the same time.

[0041] 4. If Figure 4 As shown, place half of the silicone rubber mold in the space surrounded by the template and the mold frame, inject gypsum-type slurry or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com