Preparation method of alkyd resin

A kind of technology of alkyd resin and preparation steps, which is applied in the field of alkyd resin preparation, which can solve the problems of difficult to meet the requirements of water resistance and adhesion, difficult to meet the requirements of "triphenyl" content, etc., and achieve easy esterification, strong activity, and improved miscibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

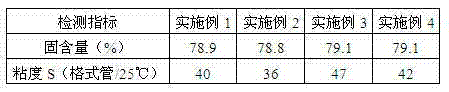

Embodiment 1

[0027] (1) Put neopentyl glycol, trimethylolpropane, phthalic anhydride, tetrahydrophthalic anhydride, and hypophosphorous acid into the reaction vessel, raise the temperature, make the materials melt and esterify at 230°C, and the generated water is discharged from the condenser;

[0028] (2) When the acid value in step (1) is esterified to 40mgkOH / g, cool down to 120°C, and add capric acid and D-40 organic solvent;

[0029] (3) Heat up, reflux at 190°C for esterification, the generated water and the reflux solvent are azeotroped and then discharged from the condenser. When the acid value is 8 mgkOH / g, dilute with butyl acetate;

[0030] (4) Cool down to 100°C and filter to obtain the alkyd resin;

[0031] The above raw materials and their weights are shown in Table 1.

Embodiment 2

[0033] (1) Put neopentyl glycol, trimethylolpropane, phthalic anhydride, tetrahydrophthalic anhydride, and hypophosphorous acid into the reaction vessel, raise the temperature to make the material melt and esterify at 240°C, and the generated water is discharged from the condenser;

[0034] (2) When the acid value in step (1) is esterified to 45mgkOH / g, lower the temperature to 140°C, and add dodecanoic acid and D-40 organic solvent;

[0035] (3) Heat up, reflux at 200°C for esterification, the generated water and the reflux solvent are azeotroped and then discharged from the condenser. When the acid value is 8 mgkOH / g, dilute with butyl acetate;

[0036] (4) Cool down to 100°C and filter to obtain the alkyd resin;

[0037] The above raw materials and their weights are shown in Table 1.

Embodiment 3

[0039] (1) Put neopentyl glycol, trimethylolpropane, phthalic anhydride, hexahydrophthalic anhydride, and hypophosphorous acid into the reaction vessel, raise the temperature to melt and esterify the materials at 200°C, and the generated water is discharged from the condenser;

[0040] (2) When the acid value in step (1) is esterified to 42mgkOH / g, cool down to 160°C, and add octanoic acid and D-40 organic solvent;

[0041] (3) Raise the temperature, reflux at 180°C for esterification, the generated water and the reflux solvent are azeotroped and then discharged from the condenser. When the acid value is 8 mgkOH / g, dilute with ethyl acetate;

[0042] (4) Cool down to 100°C and filter to obtain the alkyd resin;

[0043] The above raw materials and their weights are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com