Modified isocyanate for cold curing high resilience foam plastic and preparation thereof

A technology of isocyanate and foamed plastics, applied in the field of preparation of modified MDI, can solve the problems of high density, poor elasticity and high closed cell rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

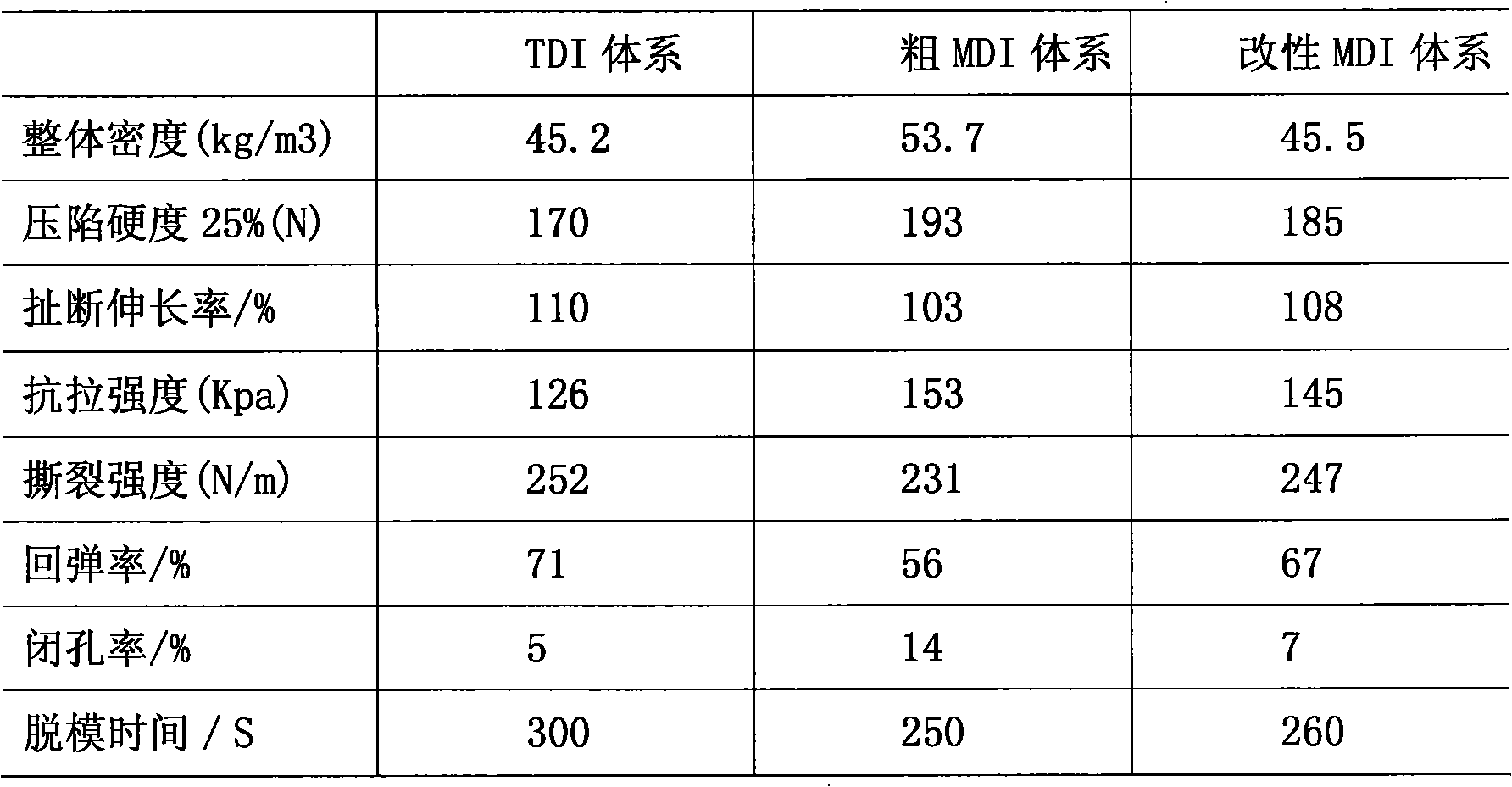

Examples

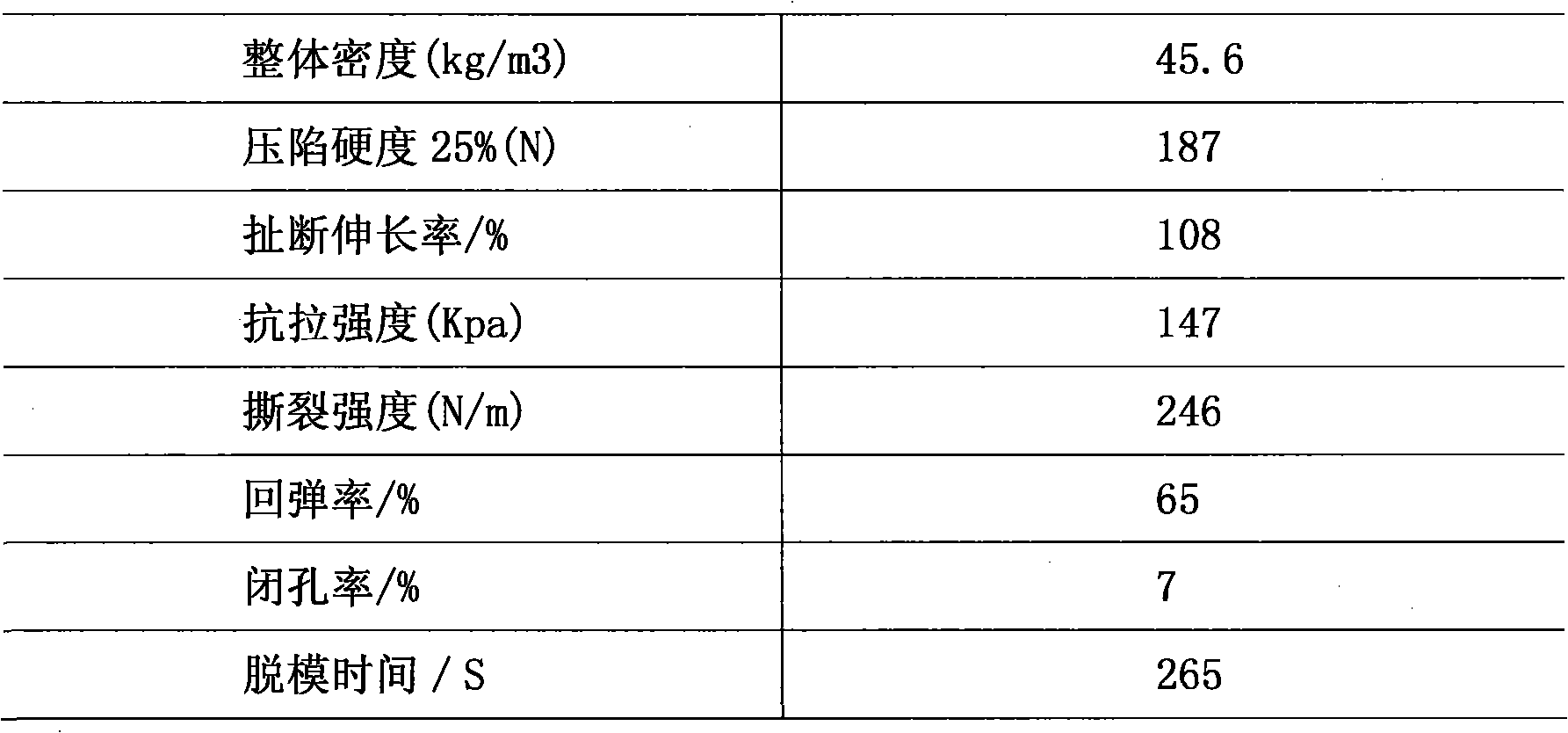

Embodiment 1

[0019] Polyether polyol (molecular weight: 6000, primary hydroxyl content: 75%): 16.5; pure MDI: 40.5; PM-200 (produced by Yantai Wanhua Polyurethane Co., Ltd.): 42; modifier (L-1160, Momentive Produced by High-tech Materials Group): 1; Phosphoric acid: 10ppm by total mass.

[0020] Preparation: Add the polyether polyol based on the formula amount into the reaction kettle at room temperature, stir at 80°C, vacuum (-0.095Mpa) for dehydration and degassing for 2-3 hours, cool down to 15°C and add isocyanate, modifier , phosphoric acid, react at 80°C for 2-3 hours, cool down to 10-40°C, and pack into barrels.

[0021] When in use: Weigh the high-resilience composite material (A component) and modified MDI (B component) according to the index of isocyanic acid index 1.0, pour the measured A component and B component into a plastic beaker, After stirring for 4-6 seconds at a stirrer speed of 3000 rpm, pour it into a 300mmX300mmX10mm mold with a mold temperature of 50°C, close the ...

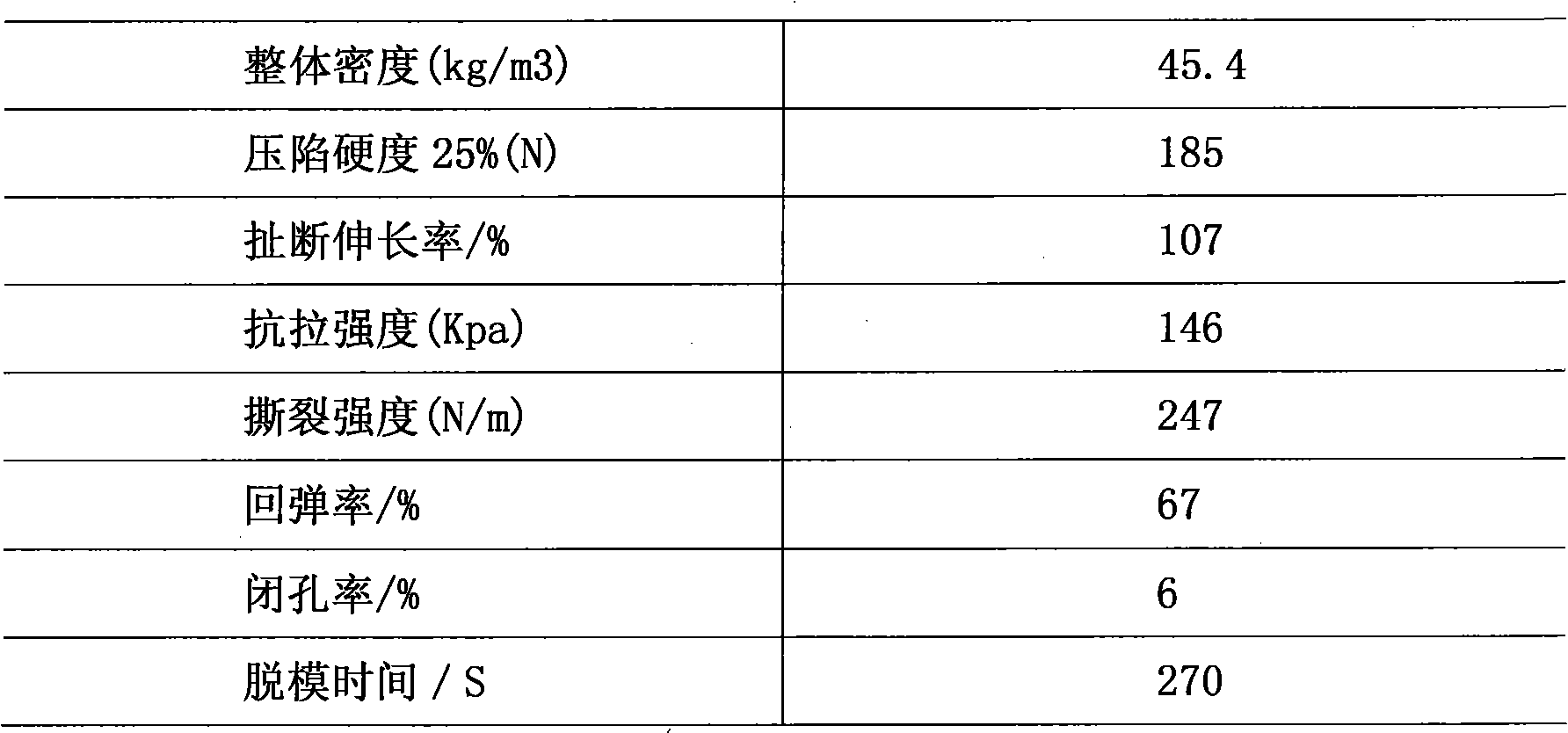

Embodiment 2

[0024] Polyether polyol (molecular weight: 7000, primary hydroxyl content: 70%): 22.5; MDI-50: 40; 44V20L (produced by Yantai Wanhua Polyurethane Co., Ltd.): 36; modifier (L-1163): 1.5; Phosphoric acid: 10PPM by total mass.

[0025] Preparation: Add the polyether polyol based on the formula amount into the reaction kettle at room temperature, stir at 100°C, vacuumize (-0.095Mpa) for dehydration and degassing for 2-3 hours, cool down to 40°C and add isocyanate, modifier , phosphoric acid, react at 85°C for 2-3 hours, cool down to 10-40°C, and pack into barrels.

[0026] When in use: Weigh the high-resilience composite material (A component) and modified MDI (B component) according to the index of isocyanic acid index 1.0, pour the measured A component and B component into a plastic beaker, After stirring for 4-6 seconds at a stirrer speed of 3000 rpm, pour it into a 300mmX300mmX10mm mold with a mold temperature of 50°C, close the mold immediately, open the mold in about 5 minu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com