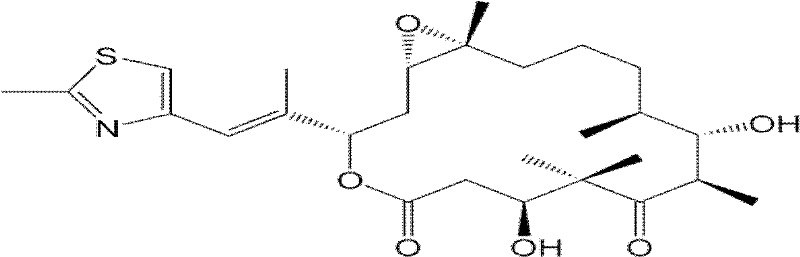

Biosynthesis method for improving yield of epothilone B

A technology for epothilone and biosynthesis is applied in the biosynthesis of industrialized production to improve the yield of epothilone B, and in the field of biosynthesis of epothilone, it can solve the problem of high production cost and low yield of epothilone B and other problems to achieve the effect of shortening the production cycle, increasing growth and increasing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: a kind of biosynthetic method of improving the productive rate of epothilone B of the present invention, the synthesis step comprises:

[0032] (1), produce starting bacterial classification, select the strong and vigorous starting myxobacterial bacterial classification as production bacterial classification by 3000rpm centrifugal shake flask bacterial liquid;

[0033] (2), solid slant expansion culture: its slant medium components are calculated by mass%, glucose 0.5%, peptone 0.5%, starch 1%, sodium chloride 0.5%, gibberellin 0.002% and agar powder 2%, The balance is water; sterilize at 120°C for 30 minutes, and after 24 hours, spread the well-grown production starting strains on a solid slant medium, and cultivate them at 30°C±2°C and relative humidity of 55% for 8 days;

[0034] (3) Inoculate the well-growing strains into the shake flask expansion medium sterilized at 120°C for 30 minutes. The components of the shake flask expansion medium are starch 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com