Laser cladding AlCoCrFeNi/NbC gradient high-entropy alloy coating material and method

A high-entropy alloy and laser cladding technology, which is applied in the coating process and coating of metal materials, can solve the problems of crack driving force and large residual stress, poor toughness of high-entropy alloy coating, and easy initiation of cracks. Good wear resistance, easy to industrialize, and avoid the effect of sudden change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

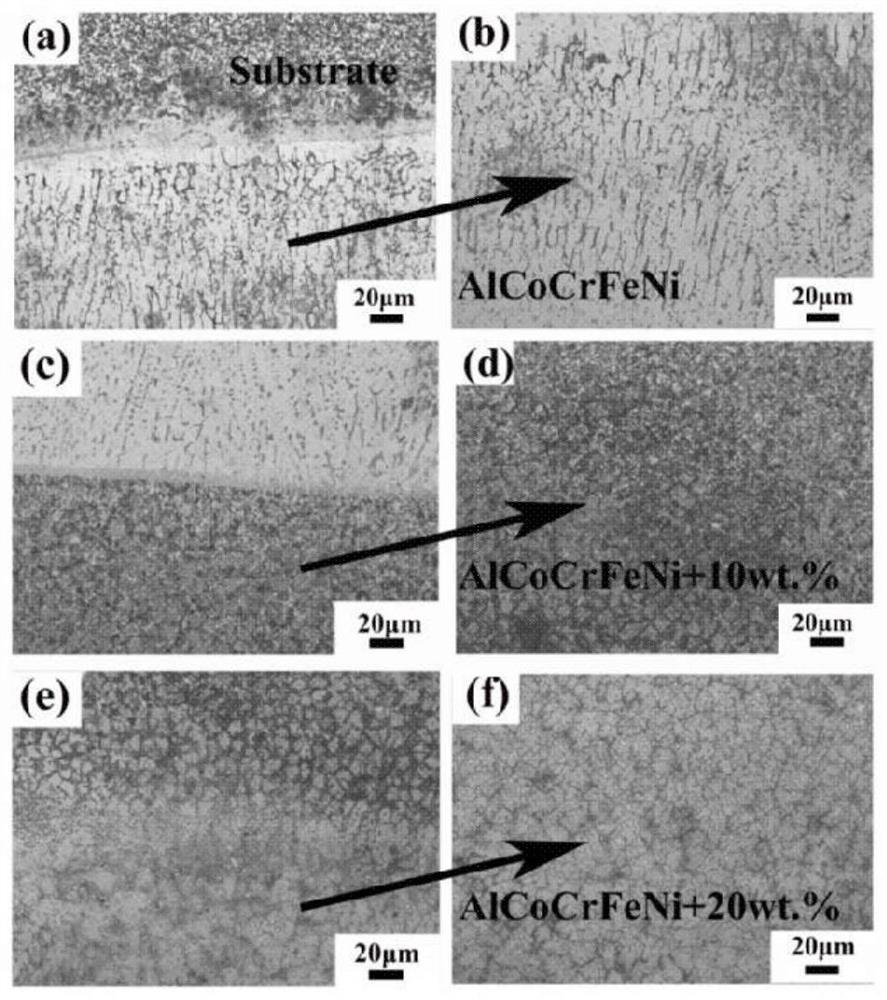

[0046] The steps of a preparation method of a laser cladding AlCoCrFeNi / NbC gradient high-entropy alloy coating material are:

[0047] (1) Al, Co, Cr, Fe, Ni elemental powders are selected to be uniformly mixed with NbC with a mass fraction of 0, 10wt%, and 20wt% respectively according to the same atomic ratio; the purity of the metal powder is greater than 99.5%, and the particle size is 100-300 Mesh, the particle size of NbC ceramic particles is 2 μm;

[0048] (2) The mixed powder is prepared by a low-energy ball milling method. The specific steps are as follows: add the mixed powder into the ball milling tank, vacuumize, control the mass ratio of the ball to the material to be 5:1, the rotation speed is 100r / min, and the ball milling time is 2h , Mix the two powders evenly, cool down for 30 minutes after the ball milling, and take out the powder; the ball milling tank used is a vacuum stainless steel tank, and the balls used are stainless steel balls without adding ball mil...

Embodiment 2

[0058] The steps of a preparation method of a laser cladding AlCoCrFeNi / NbC gradient high-entropy alloy coating material are:

[0059] (1) Al, Co, Cr, Fe, Ni element powders are selected to be uniformly mixed with NbC with a mass fraction of 0, 5wt%, and 15wt% respectively according to the same atomic ratio; the purity of the metal powder is greater than 99.5%, and the particle size is 100-300 Mesh, the particle size of NbC ceramic particles is 2 μm;

[0060] (2) The mixed powder is prepared by a low-energy ball milling method. The specific steps are as follows: add the mixed powder into the ball milling tank, vacuumize, control the mass ratio of the ball to the material to be 5:1, the rotation speed is 100r / min, and the ball milling time is 2h , Mix the two powders evenly; the ball mill used is a vacuum stainless steel tank, and the balls used are stainless steel balls without adding ball milling media.

[0061] (3) Pretreating the 45# steel substrate, the specific steps inc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com