ZnCo2O4@MnO core-shell heterostructure nanotube array material, and preparation method and application thereof

A nanotube array and manganese dioxide technology, applied in the field of nanomaterials, can solve the problems of low energy density and power density, difficult application requirements, short cycle time, etc., achieve high energy density and power density, low production cost, good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

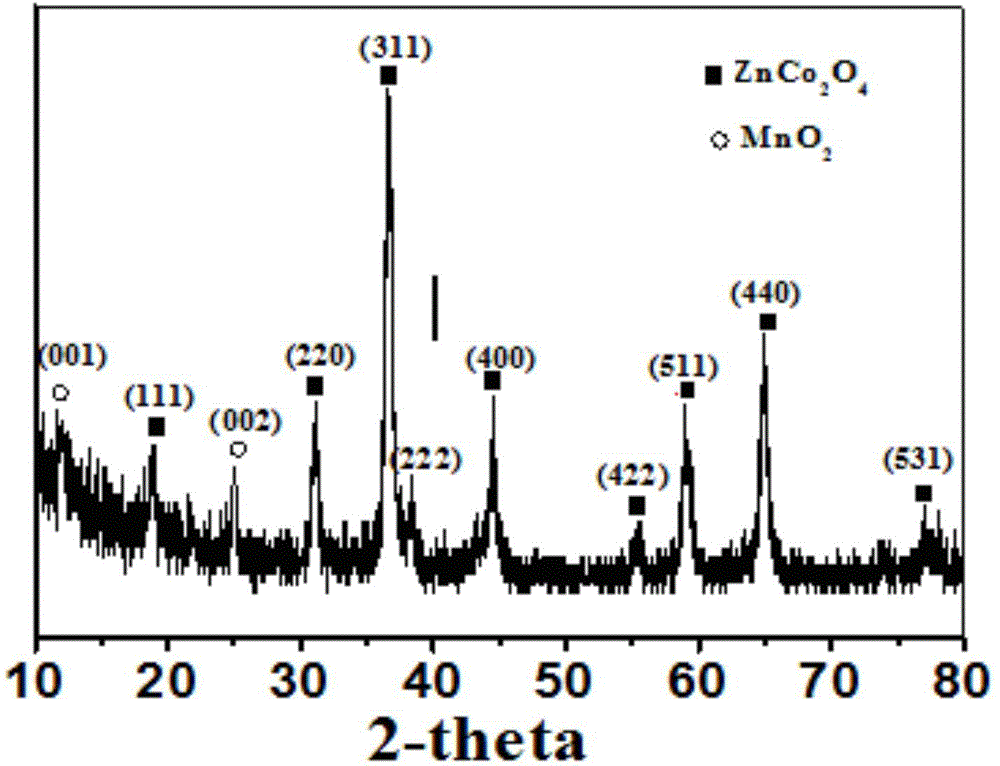

[0027] A preparation method of zinc cobaltate manganese dioxide core-shell heterostructure nanotube array material, comprising the following steps:

[0028] a. Put the nickel sheet with impurities on the surface into ethanol, acetone, dilute hydrochloric acid, and twice distilled water for 15 minutes of ultrasonic cleaning;

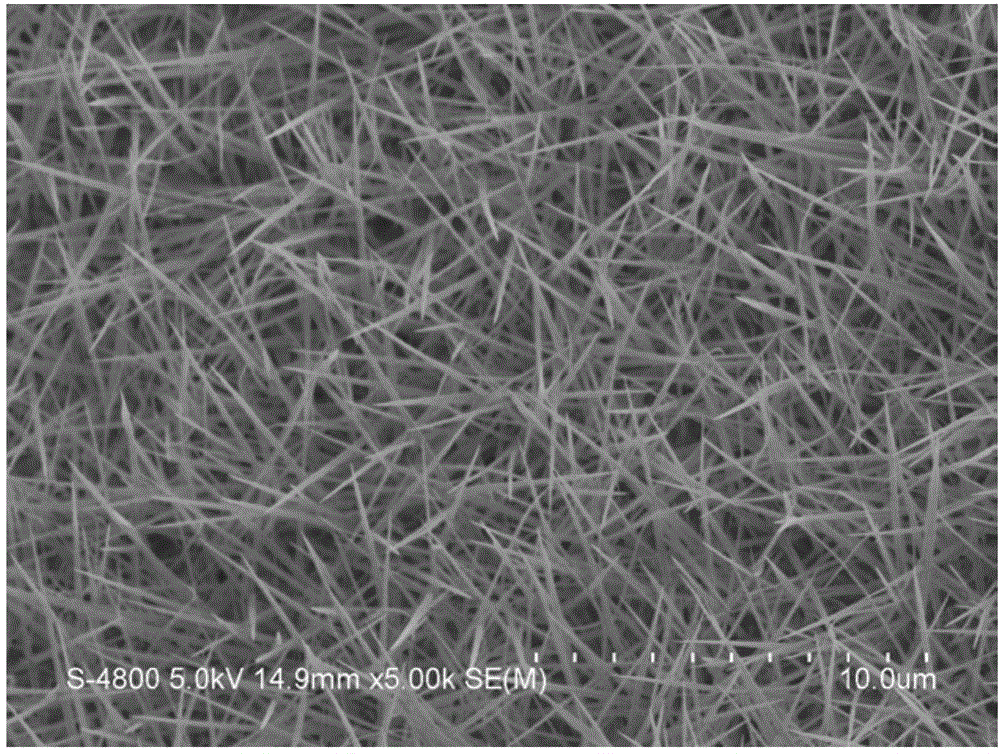

[0029] b. Mix 25mL double-distilled water, 0.2mmol zinc chloride, 0.4mmol cobalt chloride hexahydrate, 1mmol urea and 0.4mmol ammonium fluoride and add them into a 60mL reaction kettle, immerse the treated foamed nickel in the mixture, Tighten the lid of the kettle, react at 120°C for 7 hours, take out the reaction kettle and cool it down to room temperature naturally, rinse it with ethanol and double distilled water in turn, and dry it at room temperature, that is, nickel foam with zinc cobaltate nanowire arrays grown.

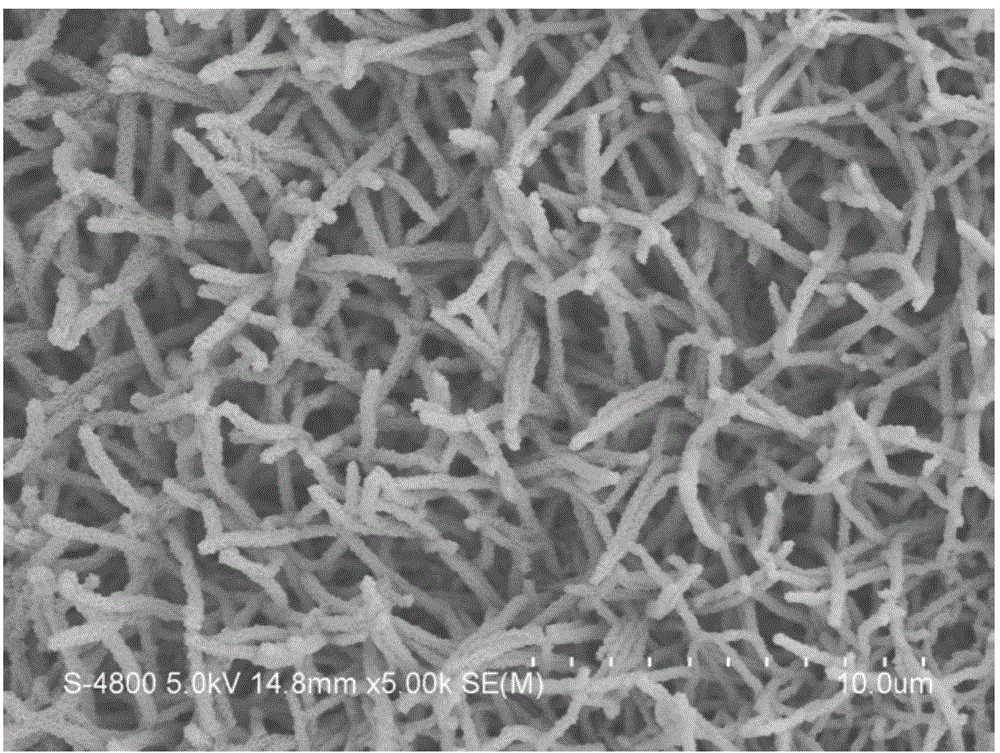

[0030] c. Dissolve 0.079015g potassium permanganate in 25mL double distilled water, add 0.25mL 12molL -1 Concentrated hydrochloric aci...

Embodiment 2

[0036] A preparation method of zinc cobaltate manganese dioxide core-shell heterostructure nanotube array material, comprising the following steps:

[0037] a. Put the nickel sheet with impurities on the surface into ethanol, acetone, dilute hydrochloric acid, and twice distilled water for 15 minutes of ultrasonic cleaning;

[0038] b. Mix 30mL double-distilled water, 0.3mmol zinc chloride, 0.5mmol cobalt chloride hexahydrate, 2mmol urea and 0.5mmol ammonium fluoride and add them into a 60mL reaction kettle, immerse the treated foamed nickel in the mixture, Tighten the lid of the kettle, react at 100°C for 9 hours, take out the reaction kettle and let it cool down to room temperature naturally, rinse it with ethanol and double distilled water in turn, and dry it at room temperature, that is, nickel foam with zinc cobaltate nanowire arrays grown.

[0039] c. Dissolve 0.079015g potassium permanganate in 25mL double distilled water, add 0.1mL 12mol L -1Concentrated hydrochloric ...

Embodiment 3

[0042] A preparation method of zinc cobaltate manganese dioxide core-shell heterostructure nanotube array material, comprising the following steps:

[0043] a. Put the nickel sheet with impurities on the surface into ethanol, acetone, hydrochloric acid, and twice distilled water for 15 minutes of ultrasonic cleaning;

[0044] b. Mix 25mL double-distilled water, 0.3mmol zinc chloride, 0.6mmol cobalt chloride hexahydrate, 1mmol urea and 0.4mmol ammonium fluoride evenly and add them to a 60mL reaction kettle, immerse the treated foamed nickel in the mixture, Tighten the lid of the kettle, react at 120°C for 5 hours, take out the reaction kettle and let it cool down to room temperature naturally, rinse it with ethanol and double distilled water in turn, and dry it at room temperature to obtain foamed nickel with zinc cobaltate nanowire arrays grown.

[0045] c. Dissolve 0.15803g potassium permanganate in 30mL double distilled water, add 0.25mL 12mol L -1 Concentrated hydrochloric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com