Method for preparing trihydrated magnesium carbonate by using continuous crystallization process

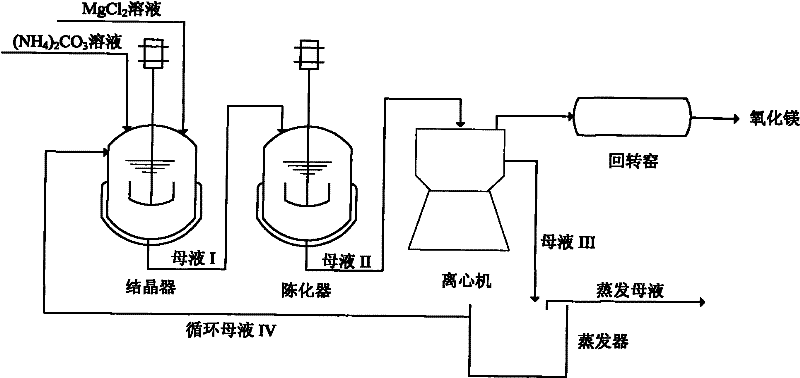

A technology of magnesium carbonate trihydrate and crystallization method, applied in directions such as magnesium carbonate, solution crystallization, etc., can solve the problem of difficult to meet the continuous crystallization production of magnesium carbonate trihydrate, disadvantageous large-scale production of magnesium carbonate trihydrate, and the particle size and particle size distribution of easily broken products. and other problems, to achieve the effect of continuous aging, good economic benefits and good crystal shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

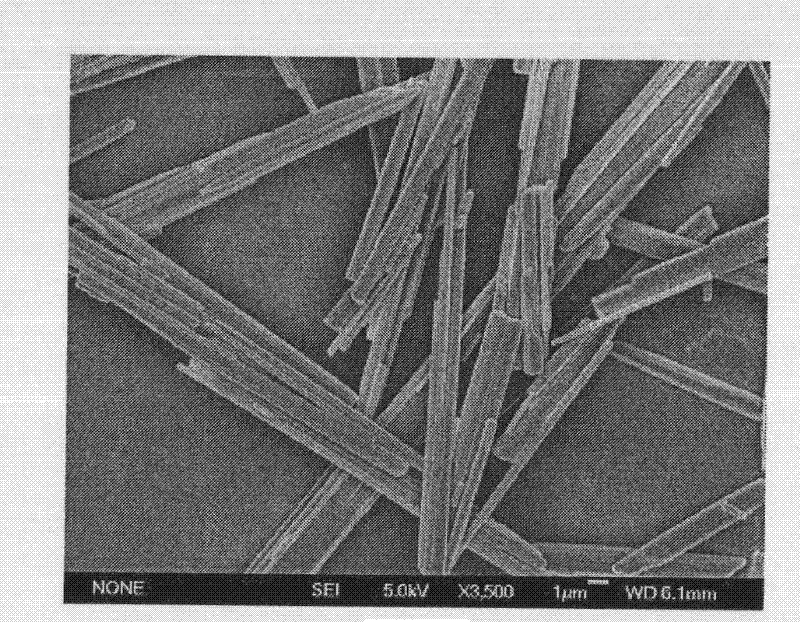

[0050] Add deionized water into magnesium chloride brine and ammonium carbonate solution respectively to prepare 0.5mol / L magnesium chloride and ammonium carbonate solution. Add 2.5kg of magnesium carbonate trihydrate seed crystals to the continuous crystallization kettle, heat the crystallization kettle to keep its solution at 10°C, start the stirring device, and start the continuous feeding of magnesium chloride solution and ammonium carbonate solution. The flow rate of the two materials is 6.7 L / min, control the stoichiometric ratio of adding magnesium chloride and ammonium carbonate to be 1:1.1, and control the pH value of the crystallization solution between 7.0 and 7.5, and the average residence time is 3 hours. When the volume of the magma in the reactor reaches the effective volume (1600L), the magma starts to flow out, and the outflow flow of the magma is the sum of the two feeds. The outflowing crystal slurry is pumped to a continuous settler for aging, and the avera...

Embodiment 2

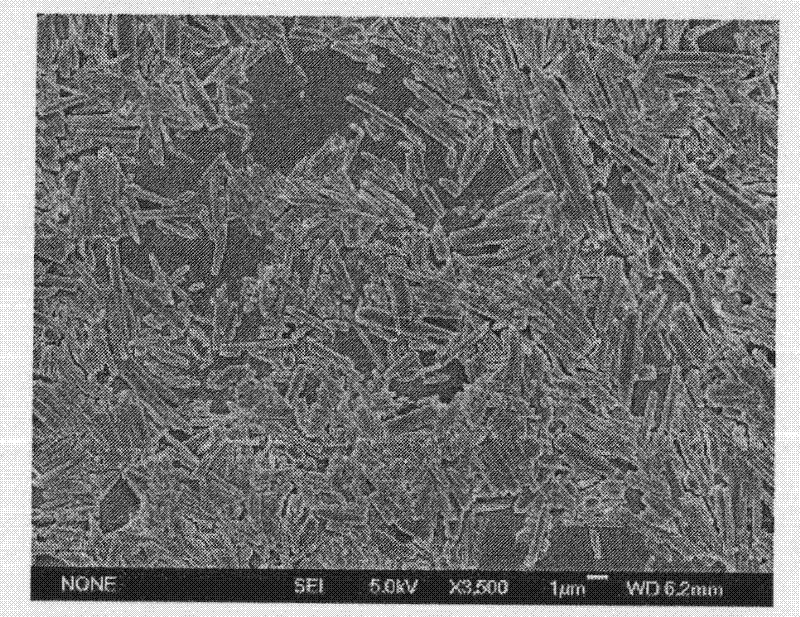

[0052] Add deionized water into magnesium chloride brine and ammonium carbonate solution respectively to prepare 3.0 mol / L magnesium chloride and ammonium carbonate solution. Add 1.0 kg of magnesium carbonate trihydrate seed crystals to the continuous crystallization kettle, heat the crystallization kettle to keep the solution at 50°C, start the stirring device, and start the continuous feeding of the magnesium chloride solution and the ammonium carbonate solution, and the flow rate of the two materials is 3L / min, control the stoichiometric ratio of adding magnesium chloride and ammonium carbonate to 1:1.2, and control the pH value of the crystallization solution between 9.5 and 10.0, and the average residence time is 0.5 hours. When the volume of the magma in the reactor reaches the effective volume (1600L), the magma starts to flow out, and the outflow flow of the magma is the sum of the two feeds. The outflowing crystal slurry is pumped to a continuous settler for aging, a...

Embodiment 3

[0054] Add deionized water to magnesium chloride brine and ammonium carbonate solution respectively to prepare 1.0 mol / L magnesium chloride and ammonium carbonate solution. Add 1.0kg of magnesium carbonate trihydrate seed crystals to the continuous crystallization kettle, heat the crystallization kettle to keep the solution at 40°C, start the stirring device, and start the continuous feeding of magnesium chloride solution and ammonium carbonate solution, the flow rate of the two materials is 5L / min, control the stoichiometric ratio of adding magnesium chloride and ammonium carbonate to 1:1.15, and control the pH value of the crystallization solution between 8.0 and 9.0, and the average residence time is 1 hour. When the volume of the magma in the reactor reaches the effective volume (1600L), the magma starts to flow out, and the outflow flow of the magma is the sum of the two feeds. The outflowing crystal slurry is pumped to a continuous settler for aging, and the average res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com