Plant type compound oil phase for emulsion explosive

A technology of composite oil phase and emulsified explosives, which is applied in the direction of explosives, non-explosive/non-thermal agent components, offensive equipment, etc., can solve problems such as insufficient water resistance, and achieve product quality, product quality control, and obvious economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

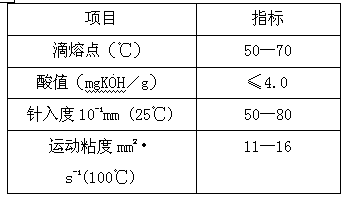

Embodiment 1

[0047] Ingredients: vegetable wax: 38%, vegetable oil: 14%, light dewaxing cream 13%, Span-80: 15%, polyisobutylene succinimide 5%, soybean lecithin: 10%, microcrystalline wax 2% , 2% petroleum resin, 1% stearyl alcohol; according to the preparation process, a vegetable-type composite oil phase for emulsion explosives is prepared.

Embodiment 2

[0049] Ingredients: Vegetable Wax: 40%, Vegetable Oil: 15%, Light Dewaxing Cream 13%, Span-80: 20%, Polyisobutylene Succinimide 7%, Polyethylene Wax 3%, Stearyl Alcohol 2% ; According to the preparation process, a plant-type composite oil phase for emulsion explosives is prepared.

Embodiment 3

[0051] Raw material components: vegetable wax: 40%, vegetable oil: 15%, light dewaxing cream 10%, Span-80: 15%, Span-80 acrylate 7%, soybean lecithin: 8%, microcrystalline wax 4%, ten Octanol 1%; according to the preparation process, a plant-type composite oil phase for emulsion explosives was prepared.

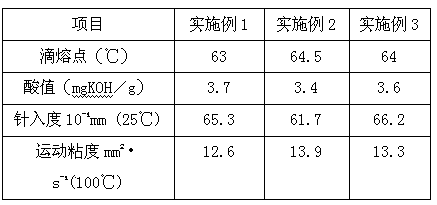

[0052] The technical requirements of the plant type composite oil phase for a kind of emulsion explosive related to the present invention are as shown in Table 1:

[0053] Table 1 Technical requirements of a plant-based composite oil phase for an emulsion explosive

[0054]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com