Nanometer material with nickel cobaltate@nickel molybdate core shell structure as well as preparation method and application of nanometer material

A core-shell structure, nanomaterial technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as low energy density and power density, difficult application requirements, short cycle time, etc. , to achieve high energy density and power density, low production cost, good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

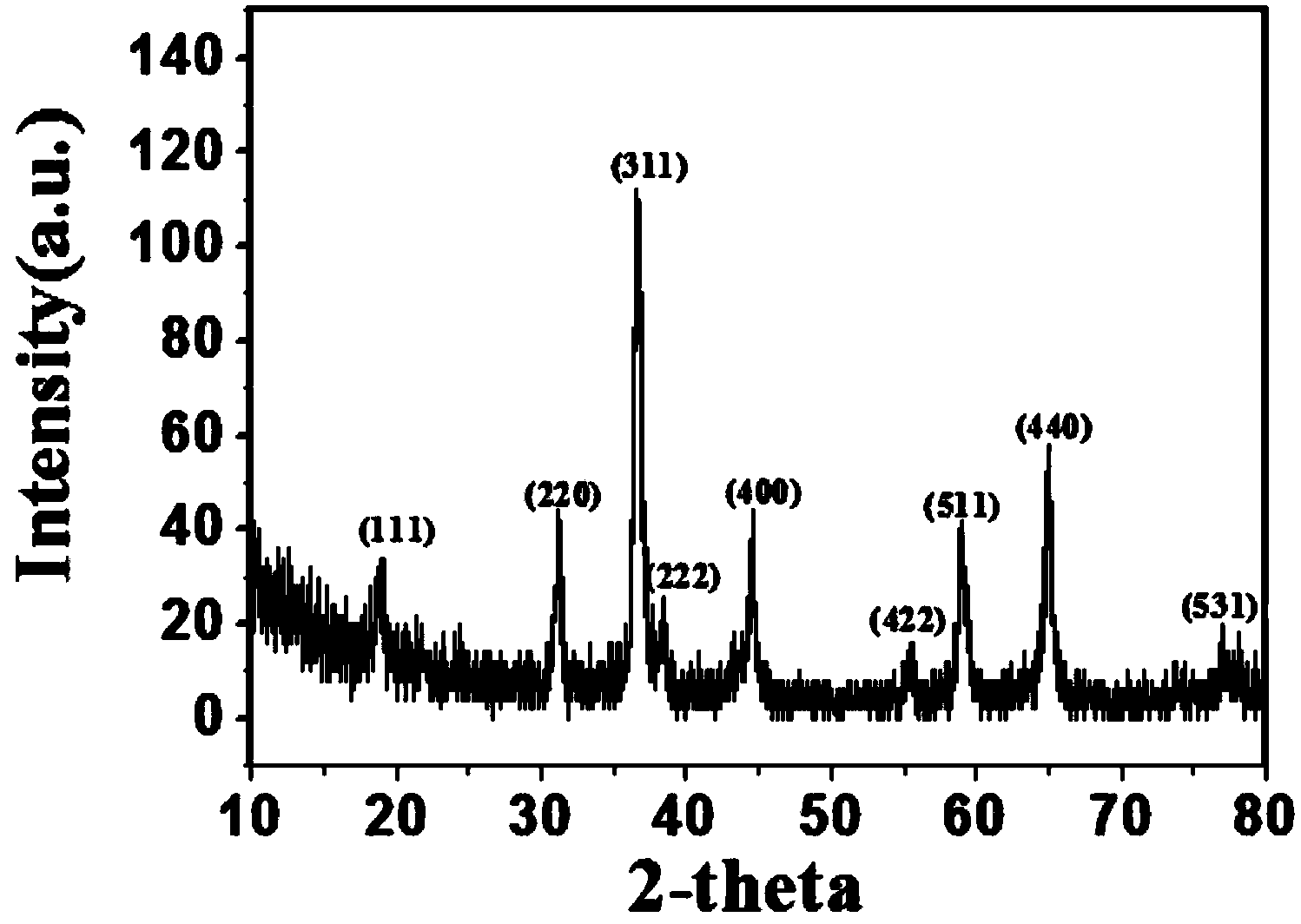

[0028] A preparation method of nickel cobaltate nickel molybdate core-shell structure nano material, comprising the following steps:

[0029] a. Put the nickel sheet with impurities on the surface into dilute hydrochloric acid, ethanol, and double distilled water in turn for ultrasonic cleaning for 20 minutes;

[0030] b. Mix 30mL double-distilled water, 1mmol nickel chloride hexahydrate, 2mmol cobalt chloride hexahydrate and 15mmol urea evenly and add them to a 60mL reaction kettle, immerse the treated foamed nickel in the mixed solution, and pour it into the reaction kettle. Tighten the lid of the kettle, react at 120°C for 6 hours, take out the reaction kettle and let it cool down to room temperature, rinse it with ethanol and double distilled water in turn, dry it at room temperature, and calcinate it at 400°C for 3 hours in an air atmosphere to obtain the nickel cobaltate nanowire material .

[0031] c. Dissolve 0.2379g of nickel chloride hexahydrate, 0.22g of tetrahydra...

Embodiment 2

[0037] A preparation method of nickel cobaltate nickel molybdate core-shell structure nano material, comprising the following steps:

[0038] a. Put the nickel sheet with impurities on the surface into dilute hydrochloric acid, ethanol, and twice distilled water in turn for ultrasonic cleaning for 20 minutes;

[0039] b. Mix 30mL double-distilled water, 1.2mmol nickel chloride hexahydrate, 2.2mmol cobalt chloride hexahydrate and 15.2mmol urea evenly, then add them into a 60mL reaction kettle, immerse the treated foamed nickel into the mixture, and pour it into the reaction In the kettle, tighten the lid of the kettle, react at 120°C for 6 hours, take out the reaction kettle and cool it to room temperature naturally, rinse it with ethanol and double distilled water in turn, dry it at room temperature, and calcinate it at 400°C for 3 hours in an air atmosphere to obtain nickel cobaltate nanowire material.

[0040]c. Dissolve 0.2382g of nickel chloride hexahydrate, 0.24g of ammo...

Embodiment 3

[0043] a. Put the nickel sheet with impurities on the surface into hydrochloric acid, ethanol, and double distilled water in turn for ultrasonic cleaning for 20 minutes;

[0044] b. Mix 30mL double-distilled water, 1.4mmol nickel chloride hexahydrate, 2.4mmol cobalt chloride hexahydrate and 15.6mmol urea evenly, then add them into a 60mL reaction kettle, immerse the treated foamed nickel into the mixture, and pour it into the reaction In the kettle, tighten the lid of the kettle, react at 120°C for 6 hours, take out the reaction kettle and cool it to room temperature naturally, rinse it with ethanol and double distilled water in turn, dry it at room temperature, and calcinate it at 400°C for 3 hours in an air atmosphere to obtain nickel cobaltate nanowire material.

[0045] c. Dissolve 0.2386g of nickel chloride hexahydrate, 0.26g of ammonium molybdate tetrahydrate and 0.29g of urea in 35mL of twice distilled water, and stir magnetically for 20min to form a uniform mixed solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com