Aluminum base MOFs/oxidized graphene composite material and preparation method and application thereof

A composite material and graphene technology, applied in the field of material science and engineering, can solve the problems of inability to remove DMF molecules, large amount of organic solvents used, environmental pollution, etc., to achieve optimized structure and performance, shorten reaction time, and fully utilize solvents Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

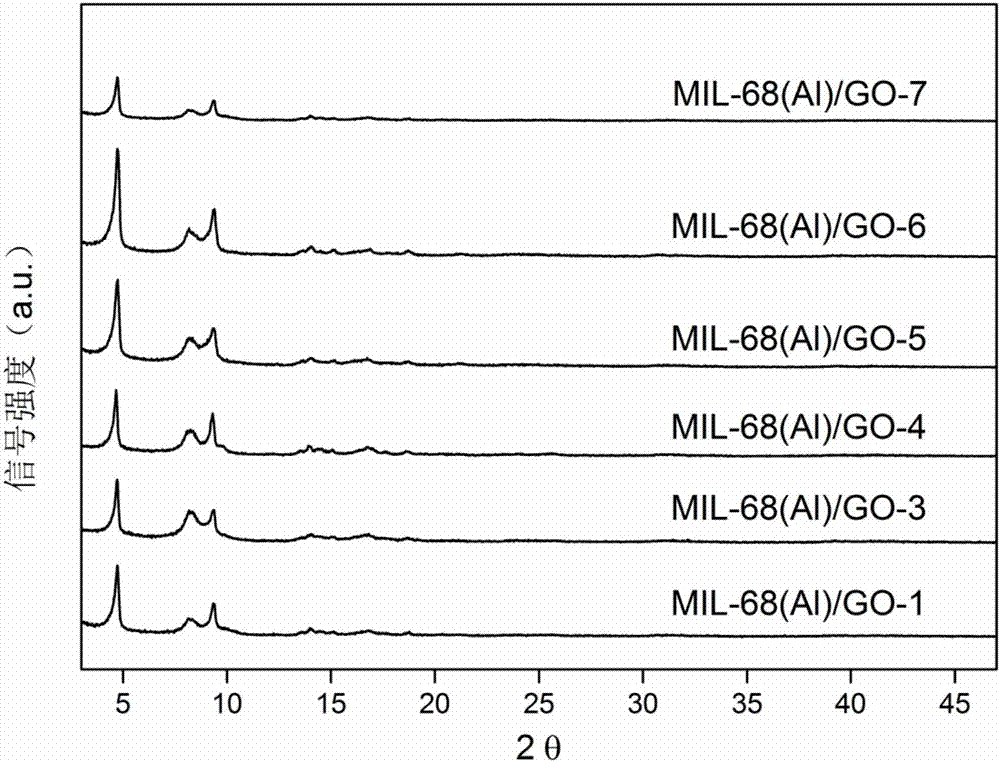

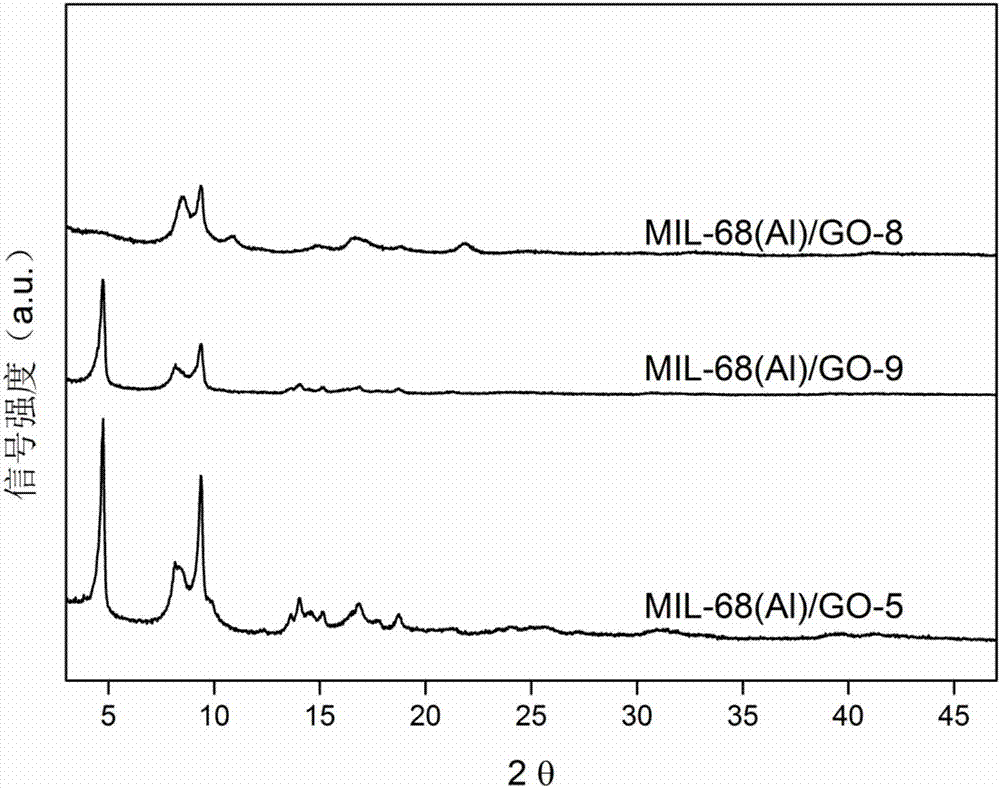

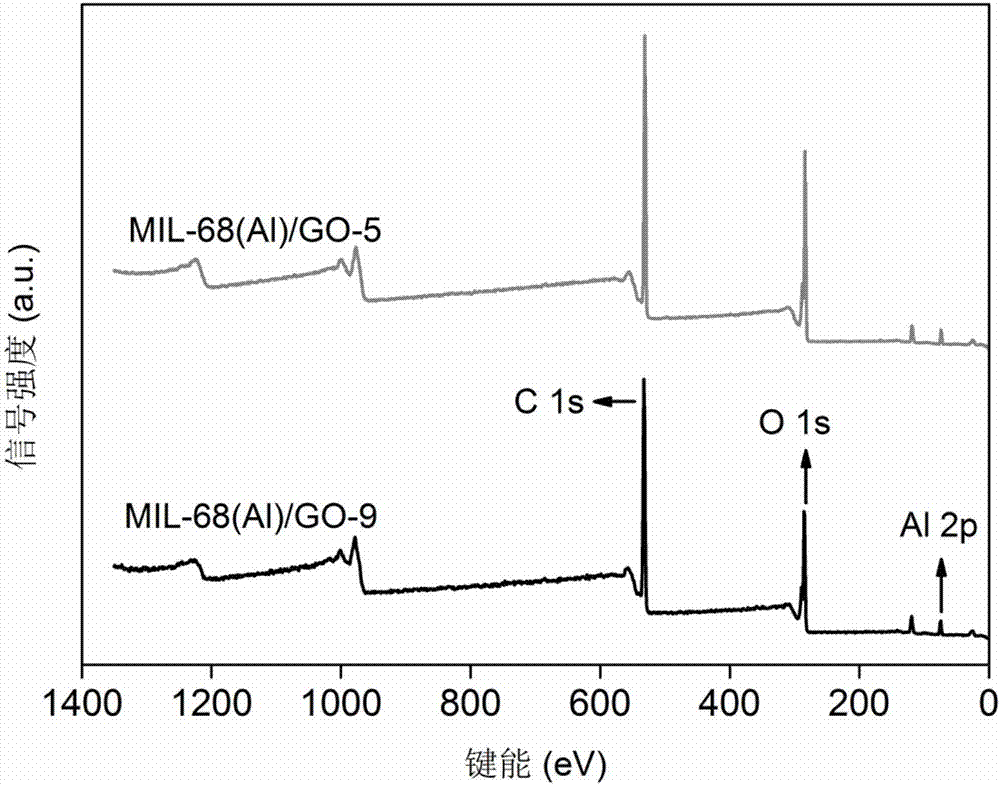

[0047] Example 1 Preparation of aluminum-based metal-organic framework / graphene oxide composite material

[0048]Disperse 1.5 mg of graphene oxide powder in 21 mL of propanol. After ultrasonic dispersion, add 4.40 g of aluminum chloride and 0.61 g of terephthalic acid. The speed of / h is raised from 60°C to 140°C, the temperature is kept at 140°C for 10h, and then naturally cooled to room temperature. The filtered product was washed 3 times with deionized water, each time for 1 h, and dried at 100°C for 10 h, and the obtained sample was labeled as MIL-68(Al) / GO-1.

Embodiment 2

[0049] Example 2 Preparation of aluminum-based metal-organic framework / graphene oxide composite material

[0050] Disperse 1.5 mg of graphene oxide powder in 21 mL of propanol. After ultrasonic dispersion, add 4.40 g of aluminum chloride and 1.53 g of terephthalic acid. The speed of / h is raised from 60°C to 140°C, the temperature is kept at 140°C for 10h, and then naturally cooled to room temperature. The filtered product was washed 3 times with deionized water for 3 hours each time, and dried at 110°C for 10 hours, and the obtained sample was labeled as MIL-68(Al) / GO-2.

Embodiment 3

[0051] Example 3 Preparation of aluminum-based metal-organic framework / graphene oxide composite material

[0052] Disperse 1.5 mg of graphene oxide powder in 21 mL of propanol. After ultrasonic dispersion, add 6.68 g of aluminum nitrate and 0.61 g of terephthalic acid. The rate of h increased from 60°C to 130°C, kept at 130°C for 10 hours, and cooled naturally to room temperature. The filtered product was washed 3 times with deionized water for 3 hours each time, and dried at 110°C for 10 hours, and the obtained sample was labeled as MIL-68(Al) / GO-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com