Lithium ion battery anode material and preparation method thereof, and lithium ion battery

A lithium-ion battery and negative electrode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of increased irreversible capacity, inability to fully utilize the high capacity of silicon, and complicated preparation processes, and achieve excellent high-rate charging Discharge performance, good initial charge efficiency, and uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] Specifically, the preparation method of the negative electrode material of the lithium ion battery provided by the invention comprises the following steps:

[0046] Step 1, mixing lithium source, M source, silicon source, and carbon source in an organic solvent to obtain a solid-liquid mixture, wherein the silicon source is a silicon source in a gel state, and the carbon source is dissolved in an organic solvent, The M source is insoluble in an organic solvent, the lithium source is selectively soluble or insoluble in an organic solvent, and the solid-liquid mixture is ball milled and dried to obtain a precursor.

[0047] In this step, aiming at the characteristics of the silicate material’s electronic conductivity and poor first coulombic efficiency, the carbon material coating is carried out. The carbon source selected for this carbon material coating must be soluble in ethanol and acetone One or more mixed carbon sources of equal polar organic solvents, for example: ...

Embodiment 1

[0069] (1) Preparation of negative electrode materials

[0070] A. Add 0.2mol LiAc·2H 2 O, 0.1mol MnCO 3 , 0.1mol Si (OC 2 h 5 ) 4 and 4.19g of glucose were added to 80g of absolute ethanol, milled with a planetary ball mill for 10 hours at a speed of 400r / min, dried and pulverized to obtain a powdery nanoscale precursor;

[0071] B. Place the precursor in a tubular resistance furnace under argon protection, heat-treat at 350°C for 4h, heat-treat at 650°C for 10h, then anneal at 500°C for 2h, and cool naturally to room temperature to obtain composite material A1. In A1, C is coated on Li 2 MnSiO 4 surface, Li 2 MnSiO 4 The content of C is 95wt%, and the content of C is 5wt%;

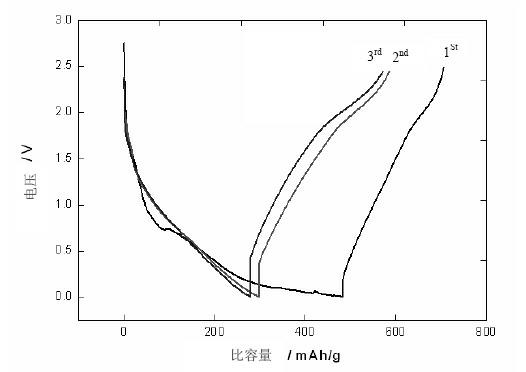

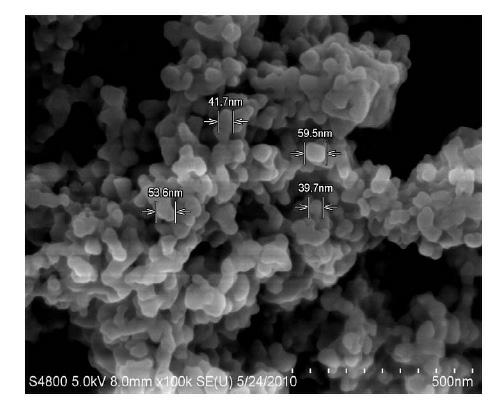

[0072] The FESEM (field emission scanning electron microscope) figure of the composite material prepared above was observed by JSM-6700F field emission scanning electron microscope of Japan Electronics Company, see figure 2 , it is observed that the particle size distribution of the composite ...

Embodiment 2

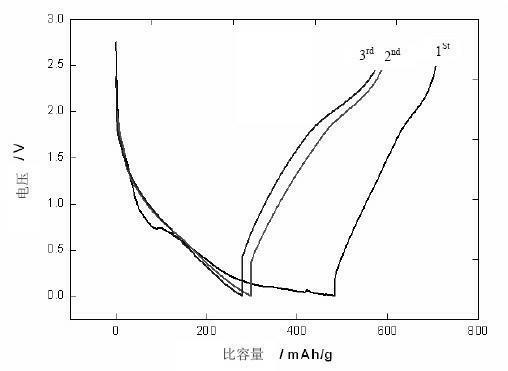

[0079] Composite materials, button batteries and full batteries were prepared in the same manner as in Example 1, except that the raw material added was 0.2mol LiAc 2H 2 O, 0.1mol ferrous oxalate, 0.1mol Si (OC 2 h 5 ) 4 and 4.19g of glucose were added to 80g of absolute ethanol to prepare carbon material coated Li 2 FeSiO 4 Composite material A2, where Li 2 FeSiO 4 The content of C is 94wt%, and the content of C is 6wt%, and the CR2016 coin cell C2 is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com