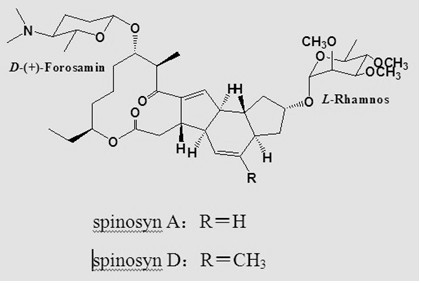

A spinosad-polylactic acid microsphere suspension and preparation method thereof

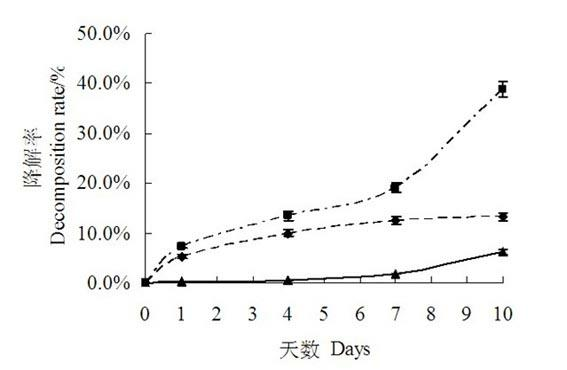

A technology of polylactic acid microspheres and spinosads, applied in the field of pesticides, to achieve the effects of improving stability, environmental friendliness, and high pesticide utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The specific steps of the preparation method of the spinosad-polylactic acid microsphere suspension are as follows:

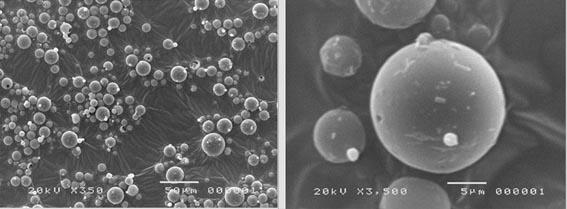

[0023] (1) The preparation method of spinosyn-polylactic acid microspheres: In an ice-water bath, weigh polylactic acid according to the ratio of raw materials and dissolve it in dichloromethane, add spinosad, stir until completely dissolved, then add gelatin solution, mix Uniform, after shear emulsification at 2000-4000 r / min for 0.2-1 min in a high-speed disperser, stir at 30-40°C at a speed of 300-600 r / min in the dark until there is no methylene chloride smell, and collect the solid and drying the spinosyn-polylactic acid microspheres at 30-60°C for 0.5-1.5 h; the concentration of the gelatin solution is 10-15 mg / mL.

[0024](2) Preparation method of suspending agent: Weigh spinosad-polylactic acid microspheres, wetting and dispersing agent, thickener, antifreeze, defoamer and water according to the ratio of raw materials, and stir evenly to obtain a...

Embodiment 1

[0040] Dissolve 0.9 g of PLA in 10 mL of dichloromethane in an ice-water bath, add 0.45 g of spinosad original drug, and stir until completely dissolved. Measure 100 mL of 12.5 mg / mL gelatin aqueous solution and mix it with the above solution, shear and emulsify at 2000 r / min in a high-speed disperser for 1 min, then stir at 30°C in the dark at a speed of 300 r / min until uniform Chloromethane odor, collect the solid and dry at 30°C for 1.5h to spinosyn-polylactic acid microspheres.

[0041] Take a certain amount of prepared and dried spinosad-polylactic acid microsphere powder (microspheres account for about 15% of the total suspension), mix sodium lignosulfonate, dispersant MF and speedo (SOPA) at a ratio of 1:1 : 2 with a total dosage of 50 mg / mL as a wetting and dispersing agent, 30 mg / mL of magnesium aluminum silicate as a thickener and 50 mg / mL of ethylene glycol as an antifreeze, Add a small amount of silicone defoamer and appropriate amount of water and stir evenly to ...

Embodiment 2

[0044] Dissolve 0.9 g of PLA in 10 mL of dichloromethane in an ice-water bath, add 0.33 g of spinosad original drug, and stir until completely dissolved. Measure 100 mL of 12.5 mg / mL gelatin aqueous solution and mix it with the above solution, shear and emulsify at 3000 r / min for 0.5 min in a high-speed disperser, then stir at 40°C and 450 r / min in the dark until no Chloromethane smell, collect the solid matter and dry at 40°C for 1 h. spinosyn-polylactic acid microspheres.

[0045] Take a certain amount of prepared and dried spinosad-polylactic acid microsphere powder (the microsphere accounts for about 15% of the total amount of the suspending agent), mix SOPA (SOPA) and sodium lignosulfonate in a ratio of 1:1 and total Mix at 50 mg / mL as wetting and dispersing agent, use xanthan gum at 1.5 mg / mL as thickener and glycerol at 50 mg / mL as antifreeze, add a small amount of silicone defoamer and an appropriate amount of water to stir evenly to obtain 4% spinosad-polylactic a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com