Composite pavement layer-sealing method

A composite pavement and sealing technology, which is applied in the directions of roads, roads, and on-site coagulation pavements, can solve the problems that the maintenance method cannot be effectively solved and the diseases of the asphalt pavement are various, so as to avoid falling off and scattering, and achieve good smoothness. degree and stability, and the effect of delaying pavement cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

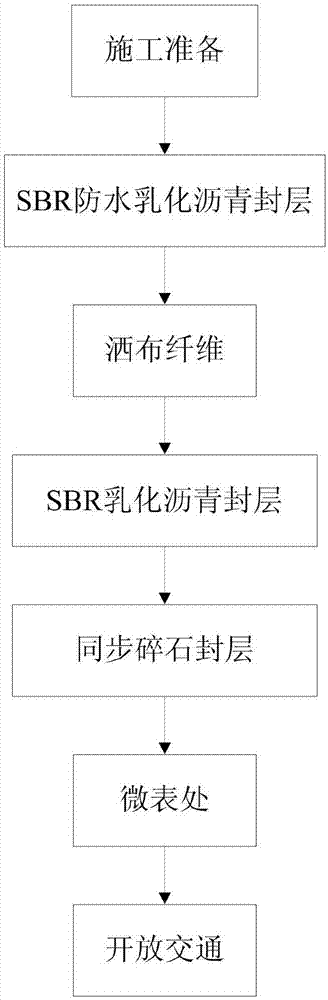

[0038] like figure 1 Shown, a kind of composite pavement sealing method, comprises the following steps:

[0039] 1. Construction preparation

[0040] Carry out a detailed road condition investigation on the original pavement, and analyze the disease situation, and design the mix ratio of the composite seal layer in a targeted manner:

[0041] 1) Road condition survey, determine the construction plan, mechanical equipment combination, staffing;

[0042] 2) Close the traffic and set up warning signs for road construction;

[0043] 2) Keep the lower layer dry and clean;

[0044] 3) Make sure the asphalt, gravel and supporting equipment are ready;

[0045] 4) Repair cracks and potholes;

[0046] 5) The structures in the construction area should be protected to avoid contamination by splashing asphalt.

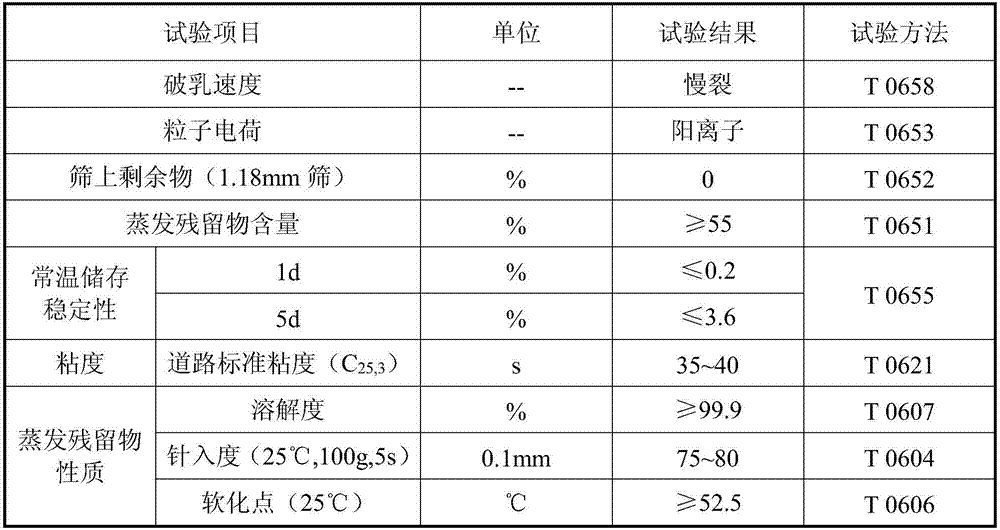

[0047] 2. SBR waterproof emulsified asphalt seal

[0048] Use an intelligent asphalt distributor to spray SBR emulsified asphalt, and the spraying amount of SBR emulsified a...

Embodiment 2

[0110] Others of this embodiment are the same as Embodiment 1, the difference is:

[0111] (1) In step (2), the spraying amount of SBR waterproof emulsified asphalt is 0.3~0.5kg / m 2 ; The SBR waterproof emulsified asphalt is slow-cracking and fast-setting type, and the raw materials are calculated in parts by weight, including 50 parts of base asphalt, 48 parts of water, 1 part of emulsifier, 3.5 parts of modifier and 1.5 parts of active catalyst. Among them, the emulsifier is a mixture of 0.23 parts of asbestos powder emulsifier and 0.77 parts of lignin emulsifier; the modifier is SBR latex, and its solid content is ≥ 60%; the active catalyst is potassium nitrate;

[0112] (2) In step (3), the spreading amount of fiber is 175g / m2 , the fiber uses a mixture of polypropylene fiber, polyethylene fiber and polypropylene fiber;

[0113] (3) In step (4), the spreading amount of SBR emulsified asphalt is 0.4kg / m 2 .

Embodiment 3

[0115] Others of this embodiment are the same as Embodiment 1, the difference is:

[0116] (1) In step (2), the spraying amount of SBR waterproof emulsified asphalt is 0.4~0.6kg / m 2 ; The SBR waterproof emulsified asphalt is slow-cracking and fast-setting type, and the raw materials are calculated in parts by weight, including 50 parts of base asphalt, 45 parts of water, 0.8 parts of emulsifier, 3.0 parts of modifier and 1.2 parts of active catalyst. Among them, the emulsifier is a mixture of 0.2 parts of asbestos powder emulsifier and 0.8 part of lignin emulsifier; the modifier is SBR latex, and its solid content is ≥ 60%; the active catalyst is potassium nitrate;

[0117] (2) In step (3), the spreading amount of fiber is 160g / m 2 , the fiber uses polyester fiber;

[0118] (3) In step (4), the spreading amount of SBR emulsified asphalt is 0.3kg / m 2 .

[0119] (4) In step (6), the mass fraction of the ore in the slurry mixture is ≥90%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| cover factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com