Wettable powder compounded of mancozeb and fosetyl-aluminium and preparation method of wettable powder

A technology of aluminum triethylphosphonate and wettable powder, applied in the field of pesticides, can solve the problems of reducing the content of mancozeb components, restricting the promotion and use of compound products, complex process methods, etc. The effect of greatly reducing and simple process method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

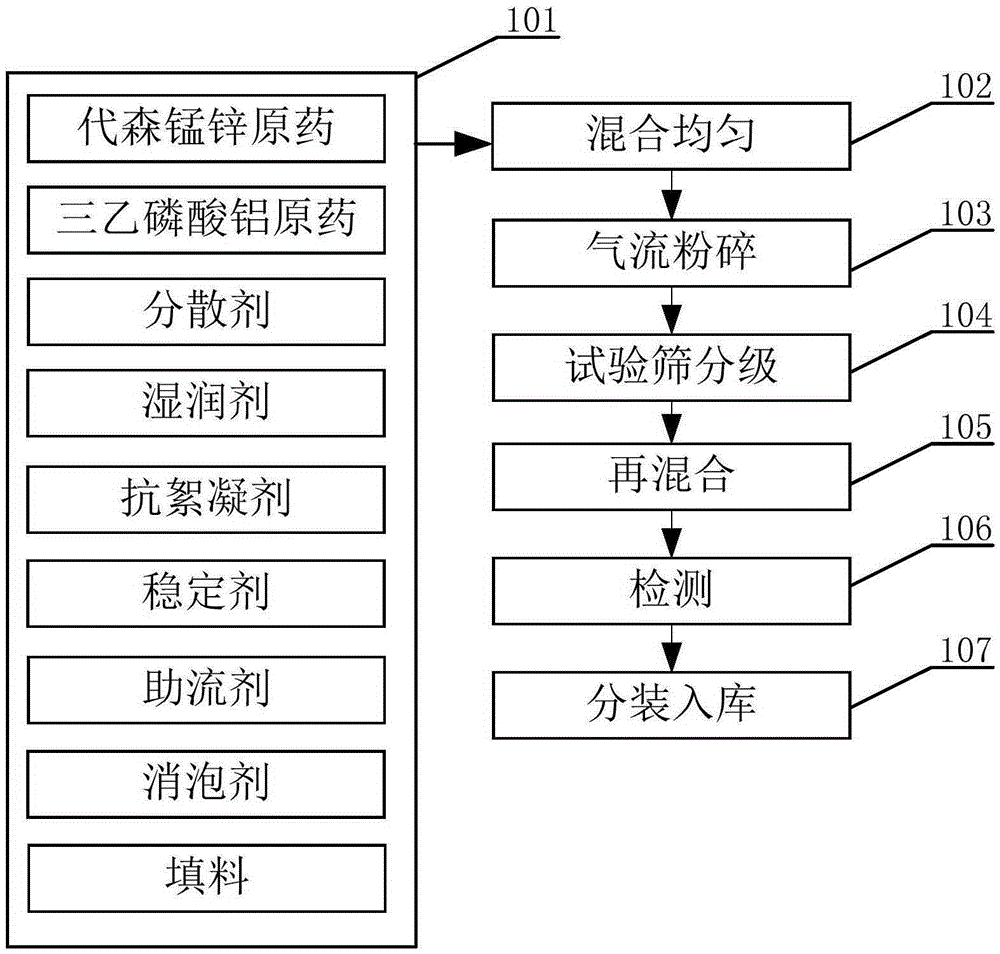

Method used

Image

Examples

Embodiment 130

[0036] Embodiment 130% mancozeb and 20% aluminum triethylphosphonate compound wettable powder

[0037] Mancozeb technical 30%, aluminum triethylphosphonate technical 20%, dispersant sodium lignosulfonate 7%, wetting agent alkylnaphthalene sulfonate 2%, deflocculant sodium tripolyphosphate 2% , stabilizer urotropine 1%, glidant white carbon black 1.5%, silicon and ether graft defoamer 0.5%, and the rest is filled with filler kaolin. Weigh the amount of each component according to the formula, mix them uniformly, and then carry out ultrafine pulverization through a jet mill with a pulverization pressure of 0.8-1Mpa, and finally classify the collected materials through a 45 μm test sieve, and mix them uniformly again to obtain 30% mancozeb and 20% aluminum triethylphosphonate compound wettable powder.

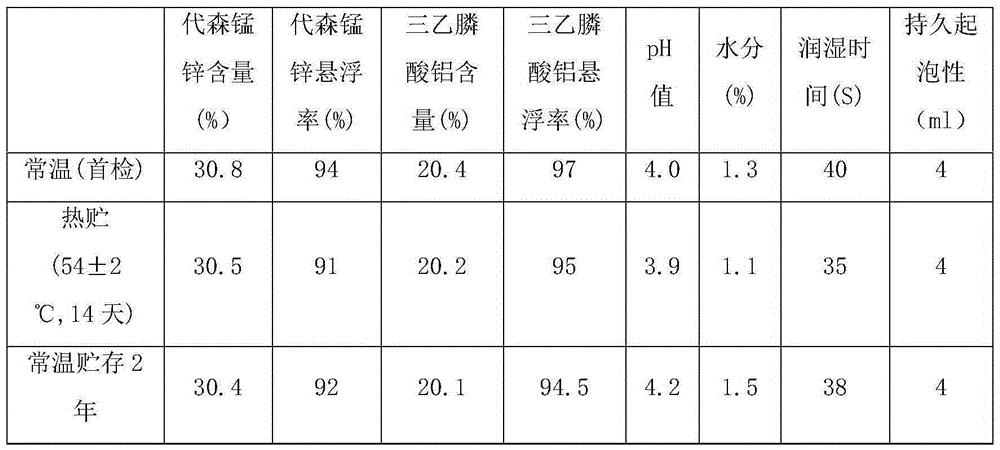

[0038] The 50% mancozeb·aluminum triethylphosphonate wettable powder prepared in Example 1 is detected, and the quality index detection results are shown in Table 1.

[0039] Ta...

Embodiment 235

[0042] The compound wettable powder of embodiment 235% mancozeb and 25% aluminum triethylphosphonate

[0043] Mancozeb technical 35%, aluminum triethylphosphonate 25%, dispersant calcium lignosulfonate 6%, wetting agent naphthalene sulfonate 2.5%, deflocculant sodium citrate 2%, stabilizer Sodium bisulfite 1.5%, glidant white carbon black 1%, -silicon and ether graft defoamer 0.5%, and the rest are filled with filler bentonite. Weigh the amount of each component according to the formula, mix them uniformly, and then carry out ultrafine pulverization through a jet mill with a pulverization pressure of 0.8-1Mpa, and finally classify the collected materials through a 45 μm test sieve, and mix them uniformly again to obtain 35% mancozeb and 25% aluminum triethylphosphonate compound wettable powder.

[0044] The 60% mancozeb aluminum triethylphosphonate wettable powder prepared in Example 2 is detected, and the quality index detection results are shown in Table 2.

[0045] Table ...

Embodiment 340

[0047] Embodiment 340% mancozeb and 25% aluminum triethylphosphonate composite wettable powder

[0048]Mancozeb technical 40%, aluminum triethylphosphonate technical 25%, dispersant sodium naphthalenesulfonate formaldehyde condensate 5%, wetting agent alkylsulfonic acid alkali metal salt and amine salt 3%, deflocculant Disodium edetate 2%, stabilizer paraformaldehyde 2%, glidant white carbon black 1.5%, silicon and ether graft defoamer 0.5%, and the rest filled with diatomaceous earth. Weigh the amount of each component according to the formula, mix them uniformly, and then carry out ultrafine pulverization through a jet mill with a pulverization pressure of 0.8-1Mpa, and finally classify the collected materials through a 45 μm test sieve, and mix them uniformly again to obtain 40% mancozeb and 25% aluminum triethylphosphonate compound wettable powder.

[0049] The 65% mancozeb·aluminum triethylphosphonate wettable powder prepared in Example 3 is detected, and the quality ind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com