Clip-type automatic small material carrying mechanism of intelligent welding equipment for aluminum formwork of building

The technology of welding equipment and handling mechanism is applied to the field of automatic handling mechanism of magazine type small material for intelligent welding equipment of building aluminum formwork, which can solve the problem of not being able to continue smoothly, delaying production time, and bending of the piston rod guide rod of the lifting cylinder. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0063] Example: see Figure 1 to Figure 18 .

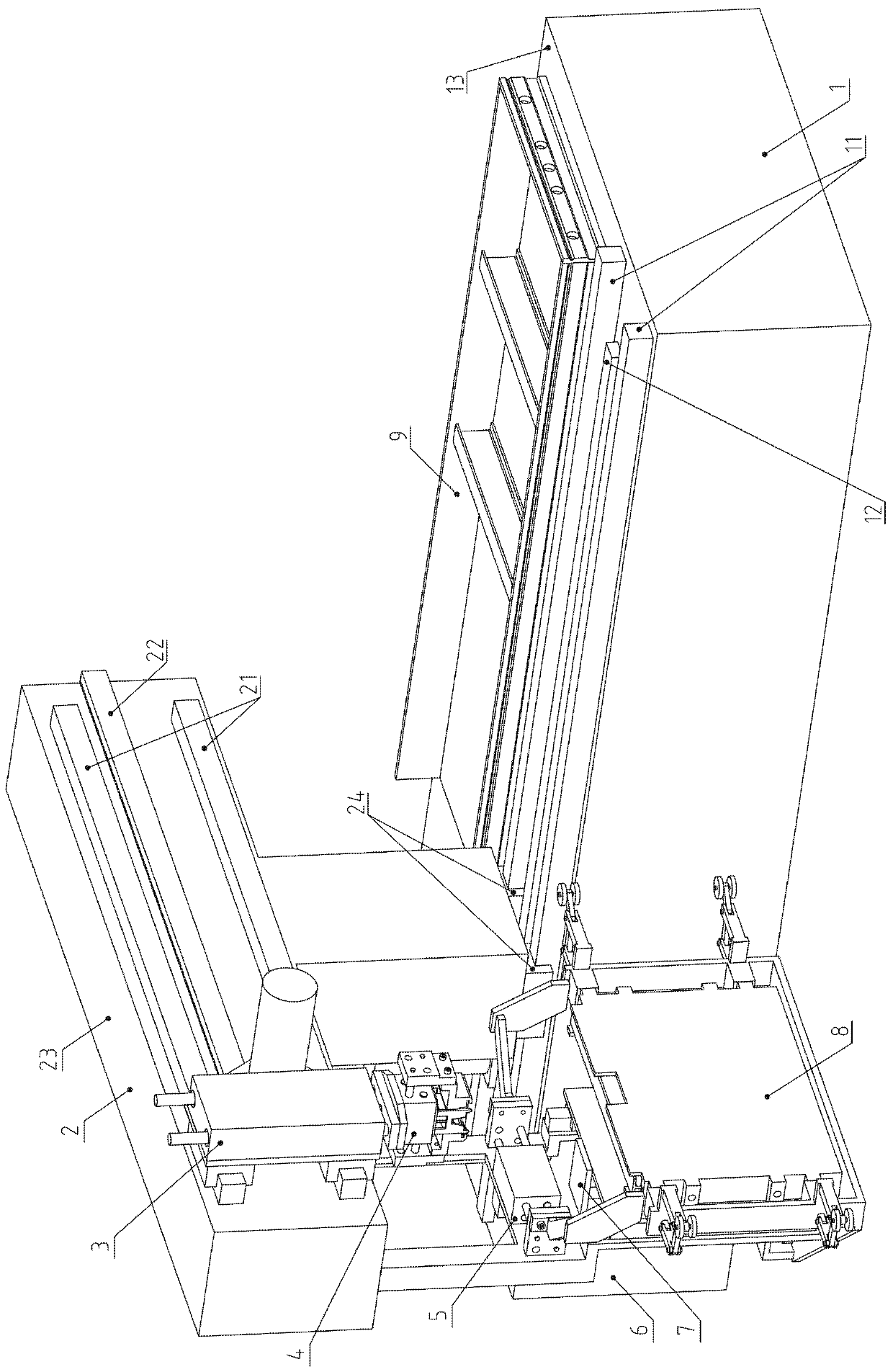

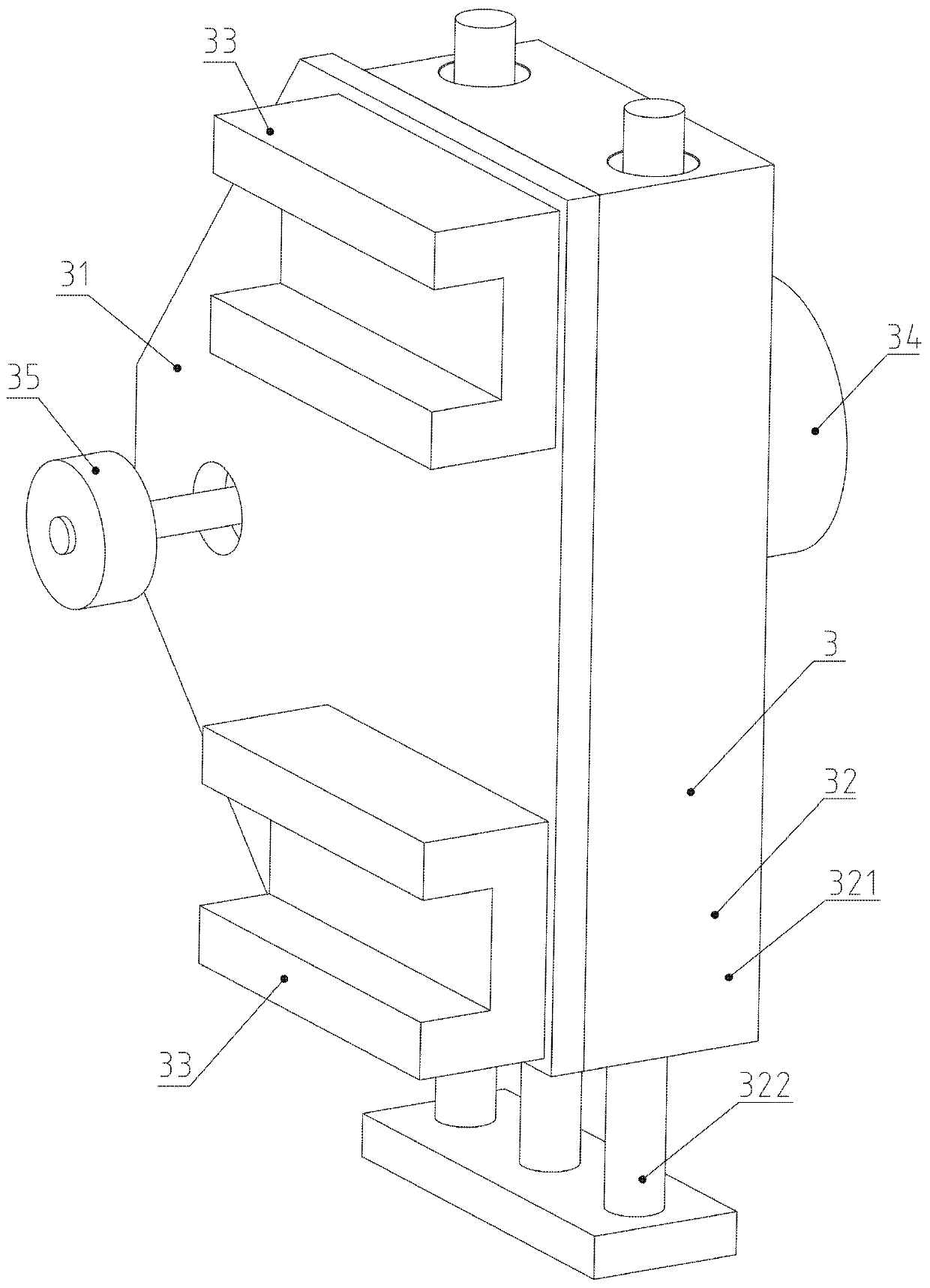

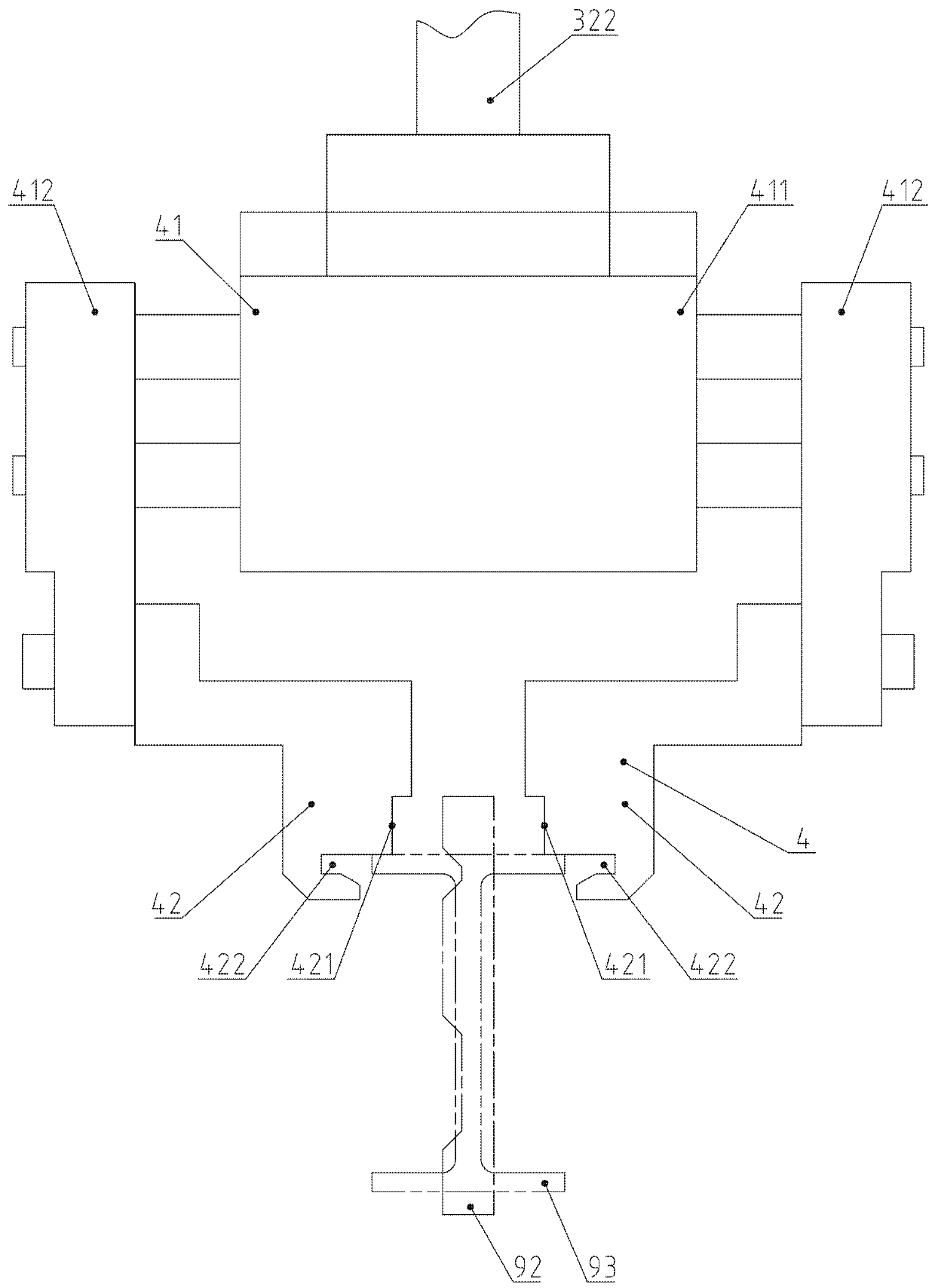

[0064] A magazine-type small material automatic handling mechanism for building aluminum formwork intelligent welding equipment, including an intelligent welding robot, a workbench assembly 1, a longitudinal movement assembly 2, a lateral movement assembly 3, a lifting and clamping assembly 4, a suspension frame assembly 6, a lifting assembly Lifting component 7 and material clip component 8;

[0065] The workbench assembly 1 includes a longitudinal linear guide rail 11, a longitudinal rack 12 and a workbench 13; the workbench 13 is fixedly connected to the frame, the longitudinal linear guide rail 11 and the longitudinal rack 12 are respectively fixedly connected to the workbench 13, and the longitudinal linear guide rail 11 and The setting direction of the longitudinal rack 12 is the front and rear horizontal direction; the aluminum template 9 is placed on the workbench assembly 1 and positioned and clamped;

[0066] The longi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com