Protein and lipid sources for use in aquafeeds and animal feeds and a process for their preparation

a technology of aquafeed and lipid sources, which is applied in the field of protein and lipid sources for use in aquafeed and animal feed and a process for their preparation, can solve the problems of affecting the profitability of salmon farming, the majority of feed costs currently used, and the largest cost of other carnivorous aquatic species culture, etc., to achieve high nutritional sources, facilitate soil irrigation and water retention in soil, and produce in a very efficient and economic manner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

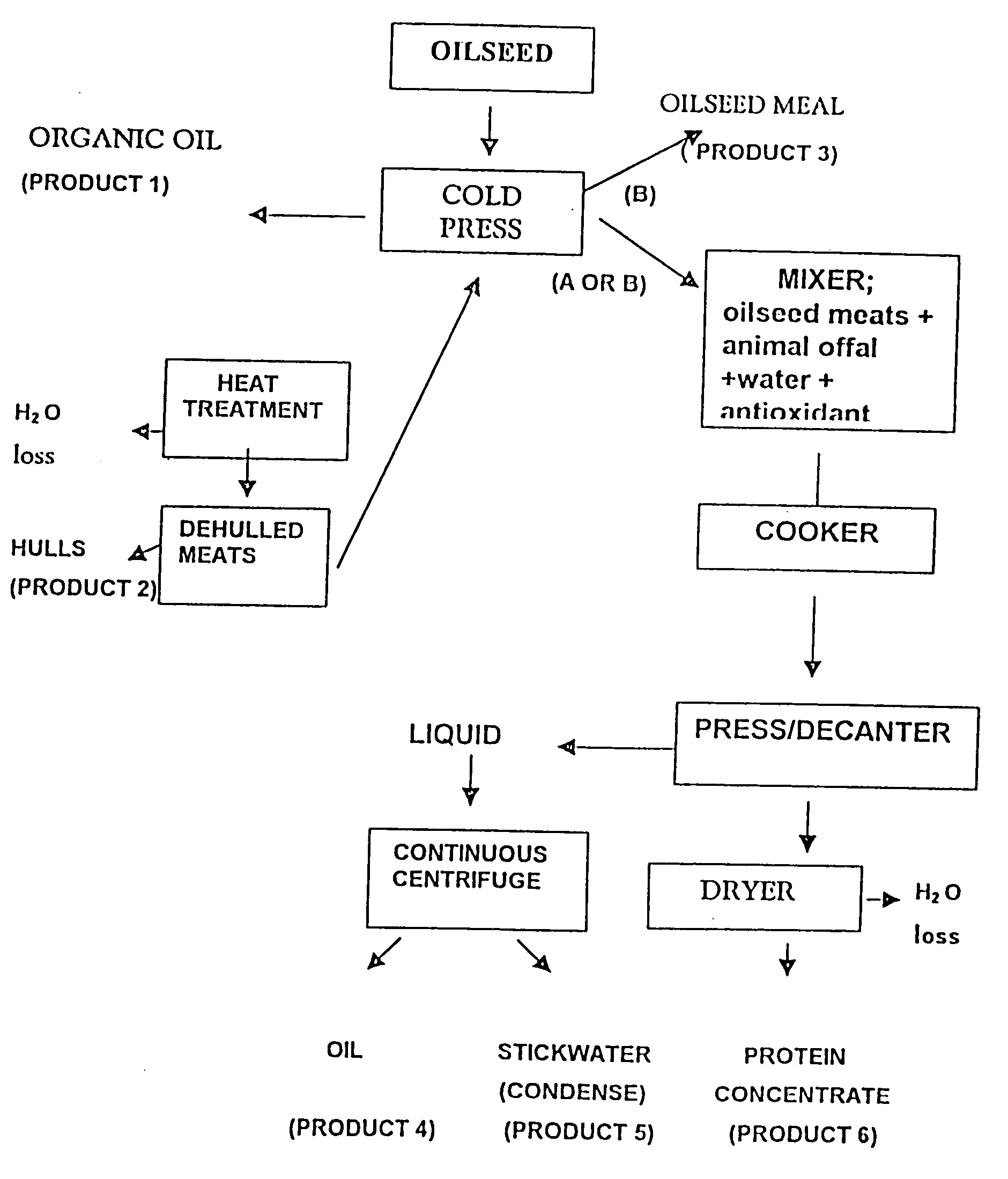

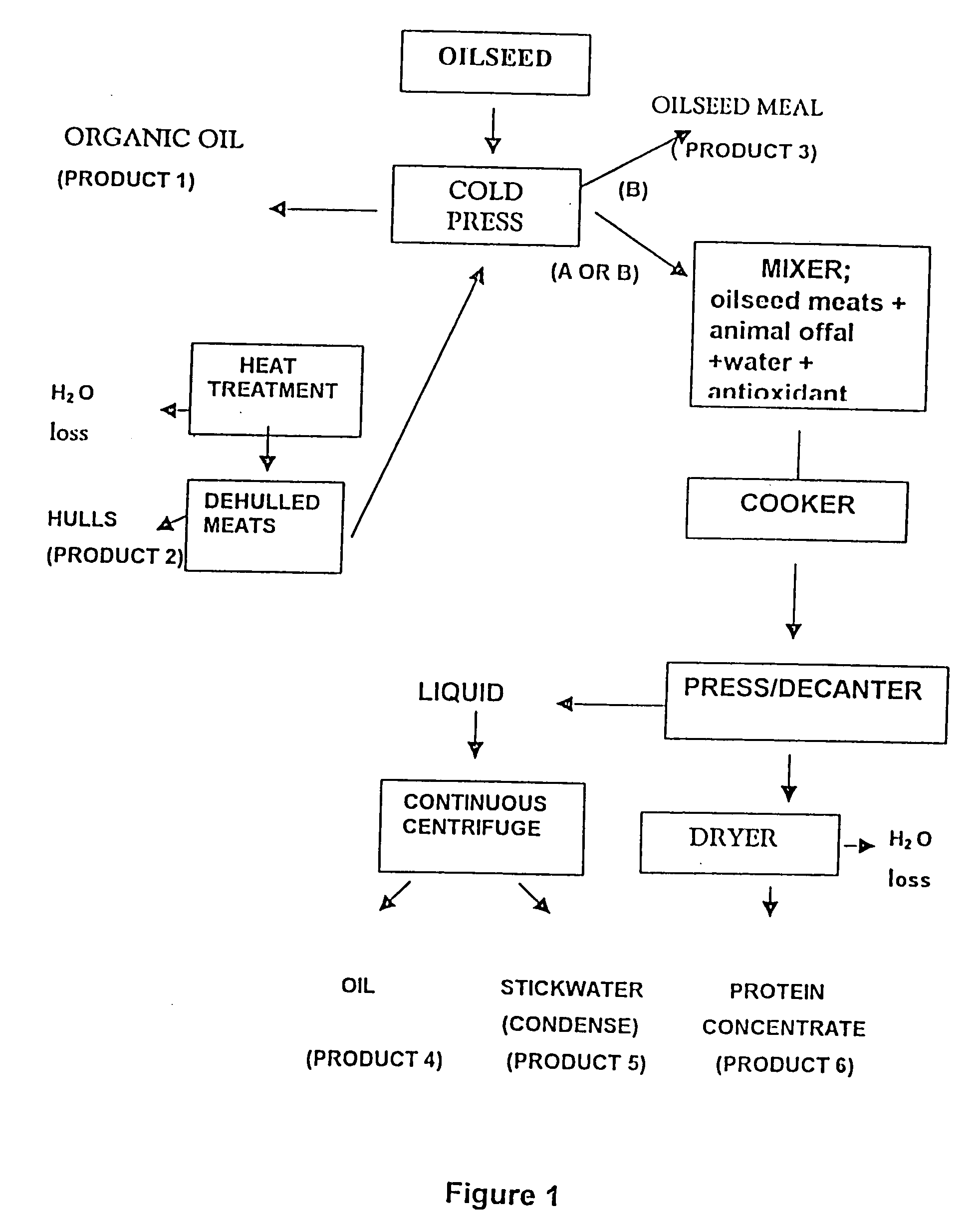

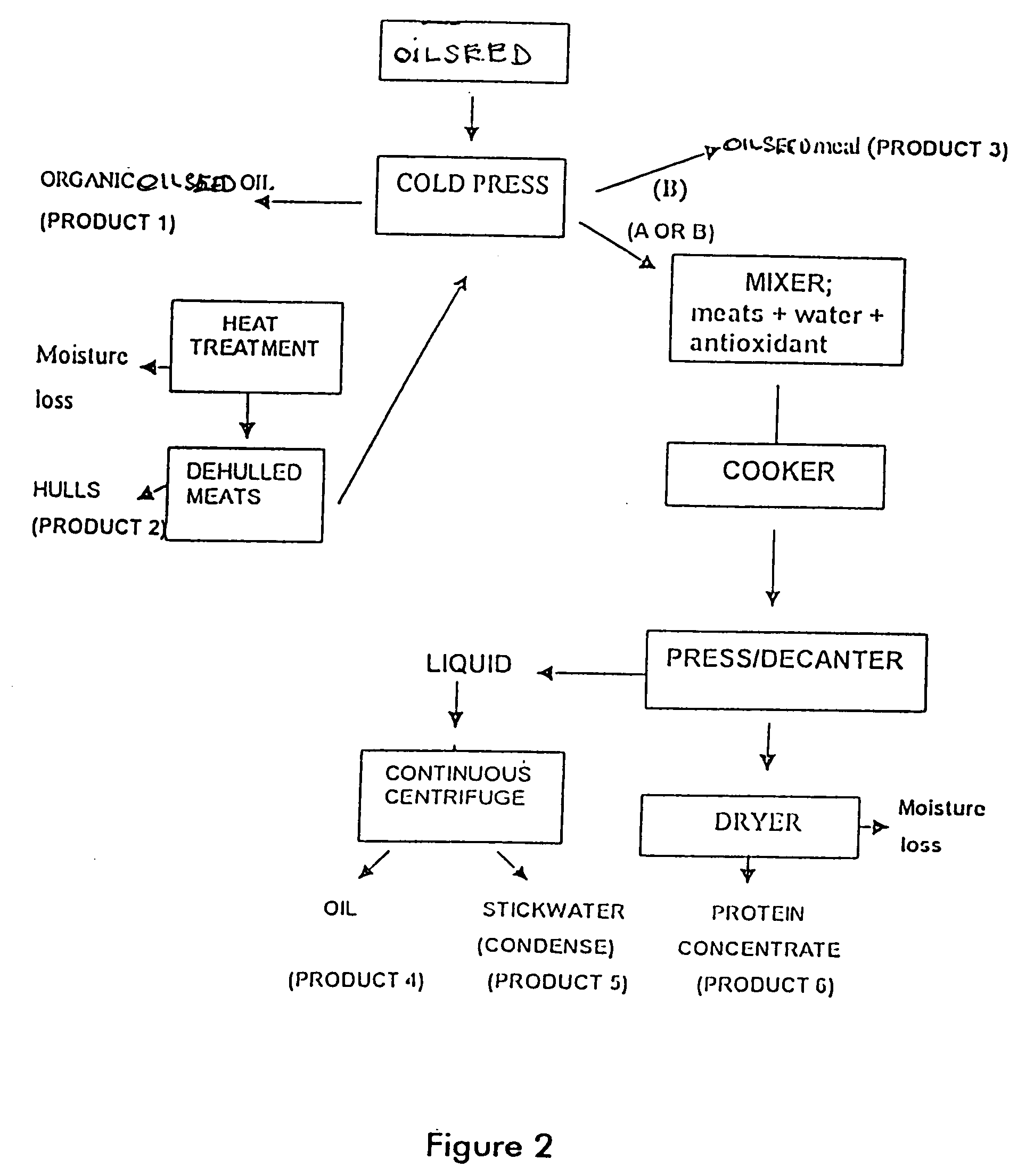

Method used

Image

Examples

example 1

Animal Offal

[0202] A common batch of whole Pacific herring was used as the main source of animal offal for the project. Soon after the herring were caught, they were rapidly block frozen by McMillan J. S. Fisheries Ltd., Vancouver, BC and stored at −40° C. for about 9 months. At this time, about 500 kg of herring were transported to the Department of Fisheries and Oceans, West Vancouver Laboratory where they were held at −20° C. until small batches of about 50 kg were partially thawed for each test run. The thawed herring were cold extruded using a Butcher Boy equipped with an auger, cutter knife, and perforated plate having holes with diameter 9.52 mm.

[0203] Fresh poultry offal (heads and viscera minus feet) was also used for some trials that involved co-processing the offal with partially dehulled animal feed grade sunflower seed (designated as batch 2 hereinafter). The offal was obtained from West Coast Reduction Ltd., Vancouver, BC and was stored for one night at −20° C. under...

example 2

Oilseeds

[0204] The four oilseeds that have been tested successfully in this project include Goliath canola seed (Cloutier Agra Seeds Inc., Winnipeg, MB), soybeans (InfraReady Products Ltd., Saskatoon SK), sunflower (completely dehulled confectionary grade seed obtained from North West Grain, St. Hilaire, Minn., USA (batch 1) and undehulled animal feed grade seed obtained from Cargill Incorporated, Wayzata, Minn., USA; batch 2), and devitalized hemp seed (Seedtec / Terramax, Qu'Appelle, SK sterilized by InfraReady Products Ltd., Saskatoon SK). Delinted glandless cottonseed (California Planting Cottonseed Distributor, Bakersfield, Calif., USA) and brown flax (InfraReady Products Ltd., Saskatoon, SK) were also tested in the process. The analytical results pertaining to products based on the former are pending. It was concluded that flax seed would be suitable for the process provided that the seed is almost totally dehulled or the outer mucilage layer of the seed coat is removed through...

example 3

Heat Treatment or Micronization of Oilseeds

[0205] In a preferred embodiment of the invention, specially for canola, soya, flax and hemp, an initial heat treatment was performed. The process involved subjecting the whole seeds to infrared energy so that the seed temperature reached 110-115° C. for 90 seconds. Subsequently, the micronized seeds were held for 20-30 min, depending upon the seed source, in an insulated tank where temperatures ranged from 100-110° C. (residual cooking conditions). These conditions inactivated enzymes such as myrosinase in canola and trypsin inhibitors in soya as well as peroxidase and cyanogenic glucosides. Further, they ensured devitalization of viable germ tissue in hemp, improved starch digestibility, and destroyed or reduced the concentrations of heat labile antinutritional factors other than those mentioned above.

[0206] Sunflower seeds (batches 1 and 2) were not micronized before co-processing with animal offal but the batch 1 seeds were dried to £...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com