Gearbox and vehicle

A gearbox and manual gearbox technology, which is applied to vehicle gearboxes, vehicle components, gear transmissions, etc., can solve the problems of difficult vehicle space layout, large radial size of gearboxes, poor noise and vibration performance, etc., and achieve improved Effects of compact layout, compact gearbox layout, weight and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

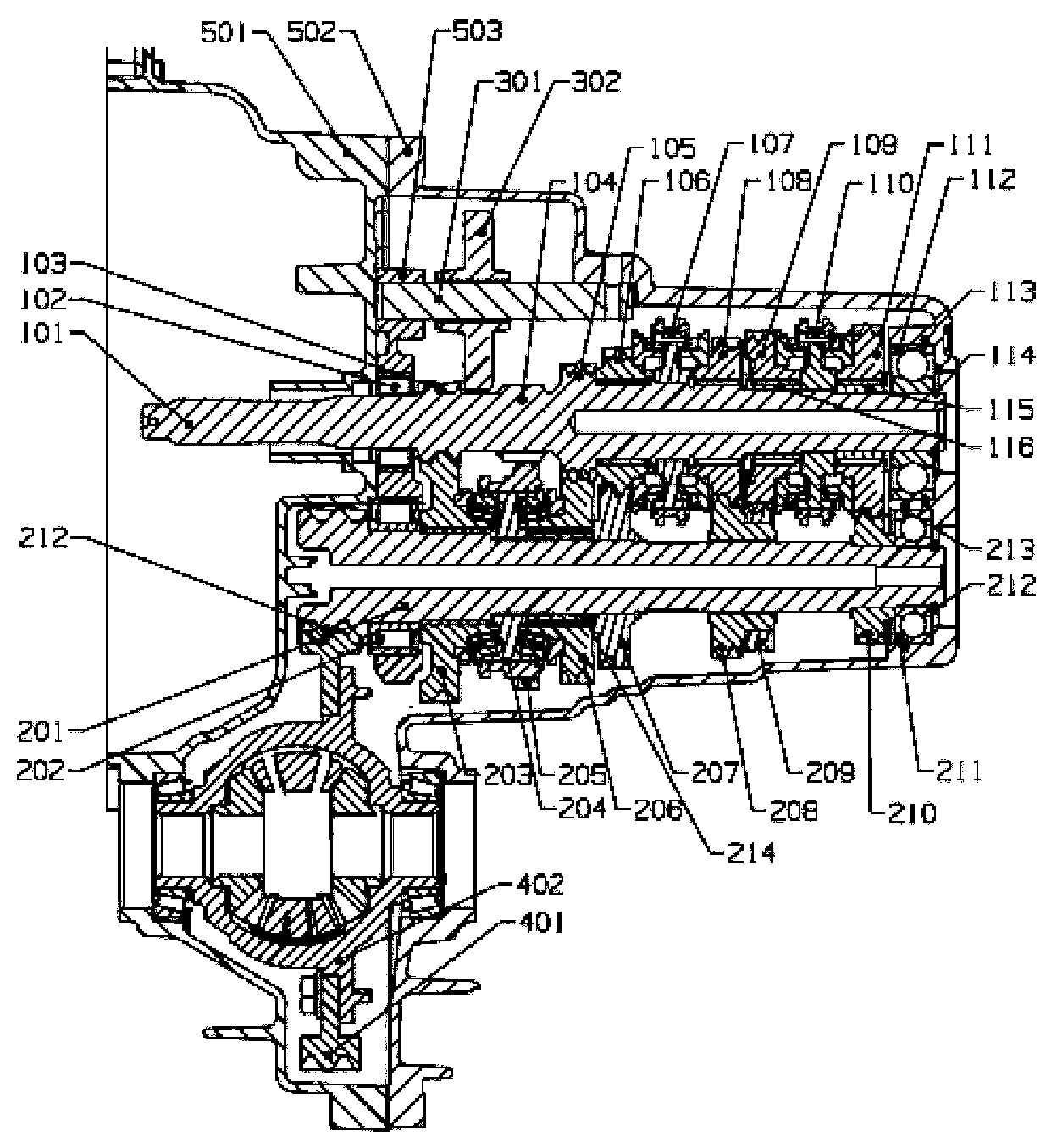

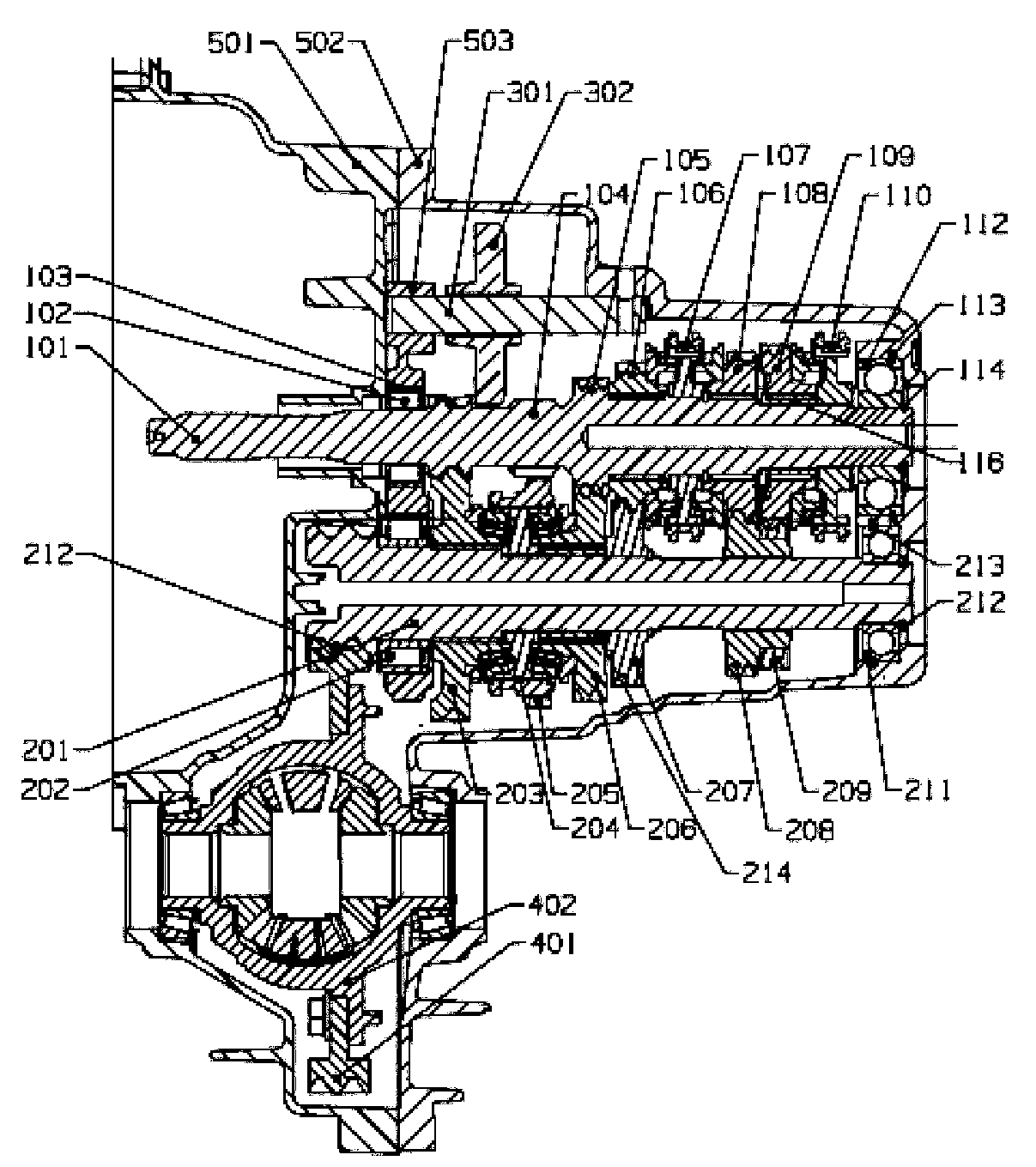

[0029] figure 1 is a schematic diagram of an embodiment of a manual transmission according to the present invention, which is a compatible six-forward manual transmission. Such as figure 1 As shown, the gearbox includes an input shaft 101 connected to the engine, an output shaft 201 selectively meshed with the input shaft 101 through a range gear, a main reduction gear 401 and a differential 402, and an inverter parallel to the input shaft 101. Blocking shaft 301.

[0030] On the input shaft 101, from front to back, there are input shaft front bearing 102, first gear driving gear 103, reverse gear driving gear 104, second gear driving gear 105, third gear driving gear 106, third / fourth gear synchronizer 107, fourth gear Gear driving gear 108, fifth gear driving gear 109, fifth / sixth gear synchronizer 110, sixth gear driving gear 111, input sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com