Nutation disc infinitely variable speed transmission

A technology of stepless speed change and transmission, which is applied in the direction of transmission, transmission parts, friction transmission, etc., can solve the problems of complex process and low transmission efficiency, and achieve complex mechanism, reduce impact and noise, and reasonable design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

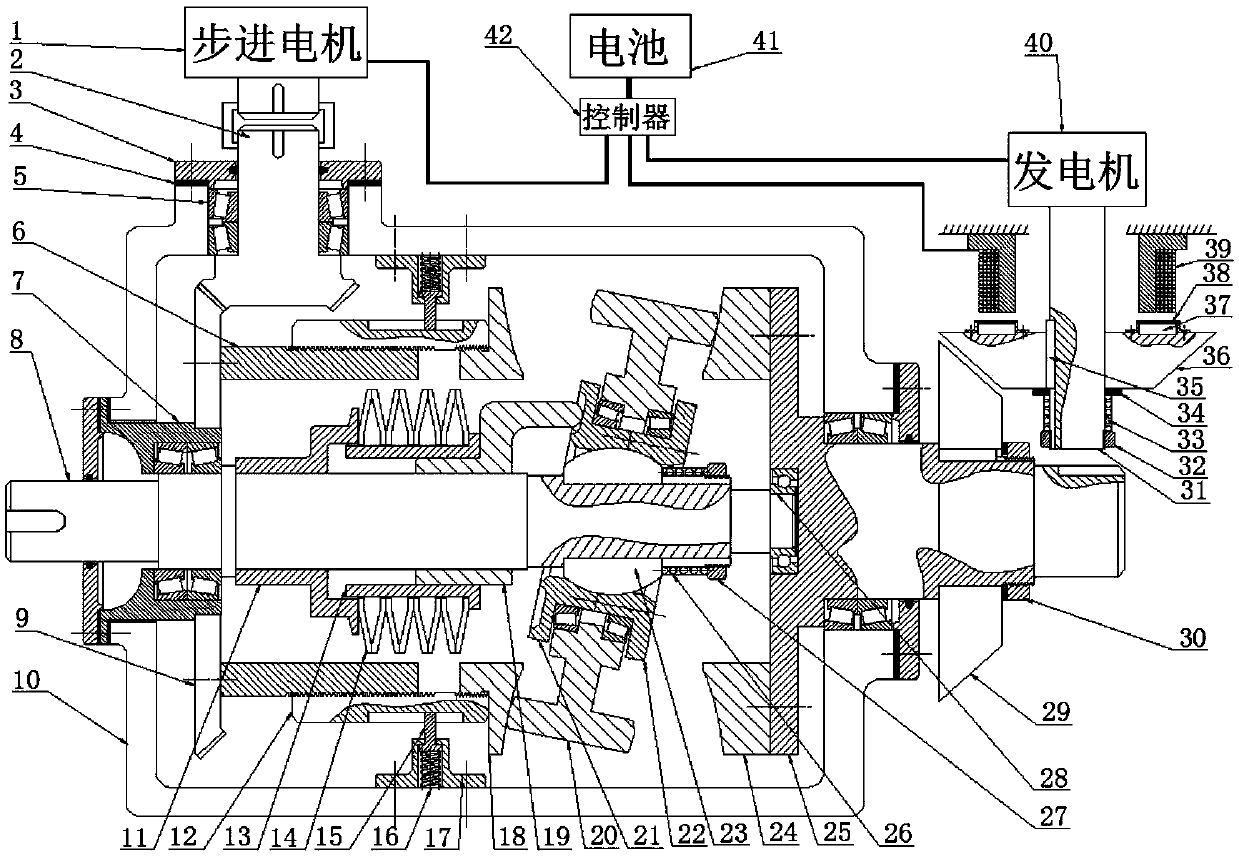

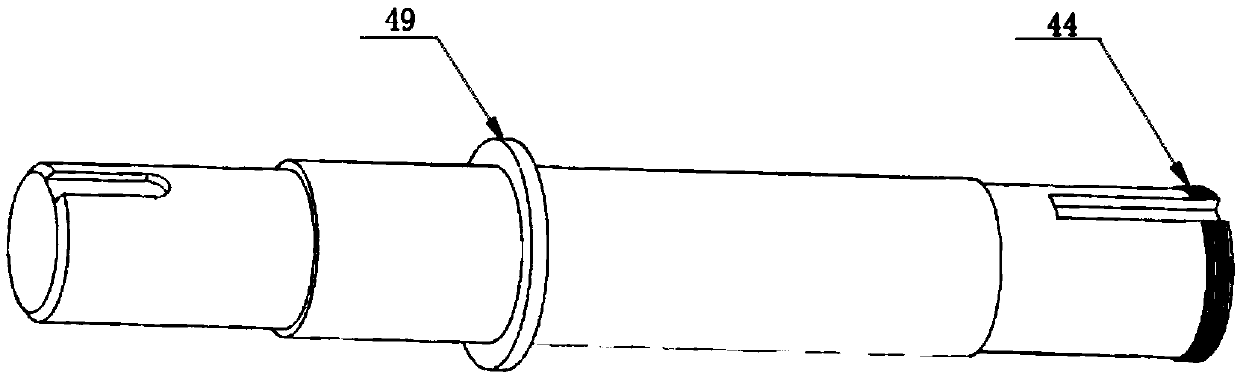

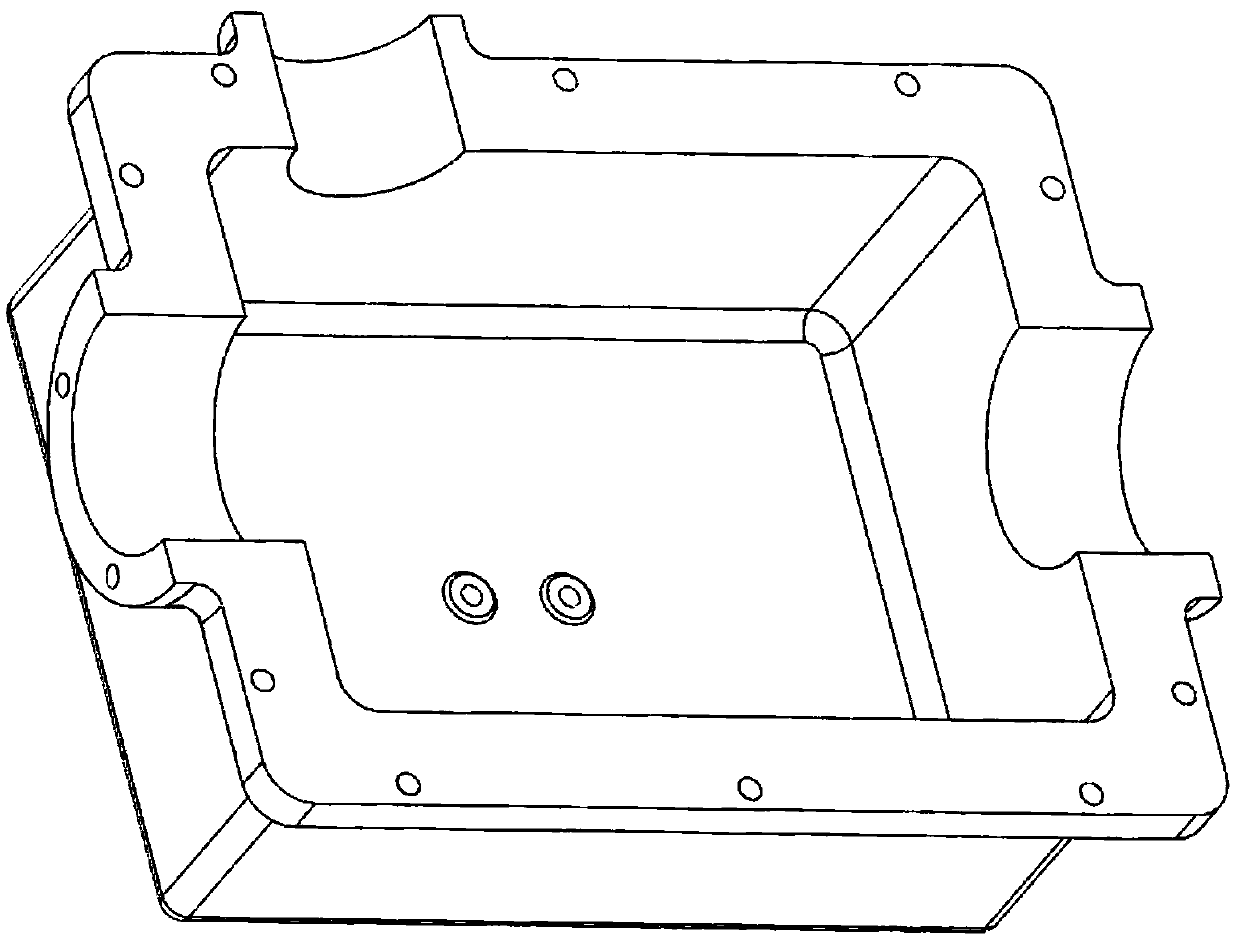

[0031] see figure 1 — Figure 11 , a nutating disc type continuously variable transmission device, which has four main functional modules: the main transmission module (input shaft, output shaft, combined offset shaft end, tapered roller bearing, first friction ring, second Friction ring, torus key, torus key tightening spring, limit nut, compression sleeve, spring sliding sleeve, disc spring and compression sleeve, etc.), power generation module (big friction cone, set nut , transmission shaft, limit nut, friction cone return spring, gasket, flat key, small friction cone, ring magnet, fixed buckle, solenoid and generator), power storage and management module (battery and controller), Speed regulation module (stepper motor, a pair of speed regulation bevel gears, threaded sleeve, transmission sleeve, limit nail, limit nail tightening spring, limit nail sleeve and first friction ring).

[0032] The input shaft 8 adopts a structure supported by double fulcrums to increase it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com