Inclined plane instrument device for measuring friction coefficient and friction angle of granular materials

A technology of friction coefficient and granular body, which is applied in the field of physical property detection of materials, can solve the problems that are not conducive to the operator to adjust while observing, the angle adjustment range is small, and the adjustment range is small, so as to achieve good equipment stability, convenient operation, The effect of increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific structure of the present invention will be further described below with reference to the drawings and embodiments.

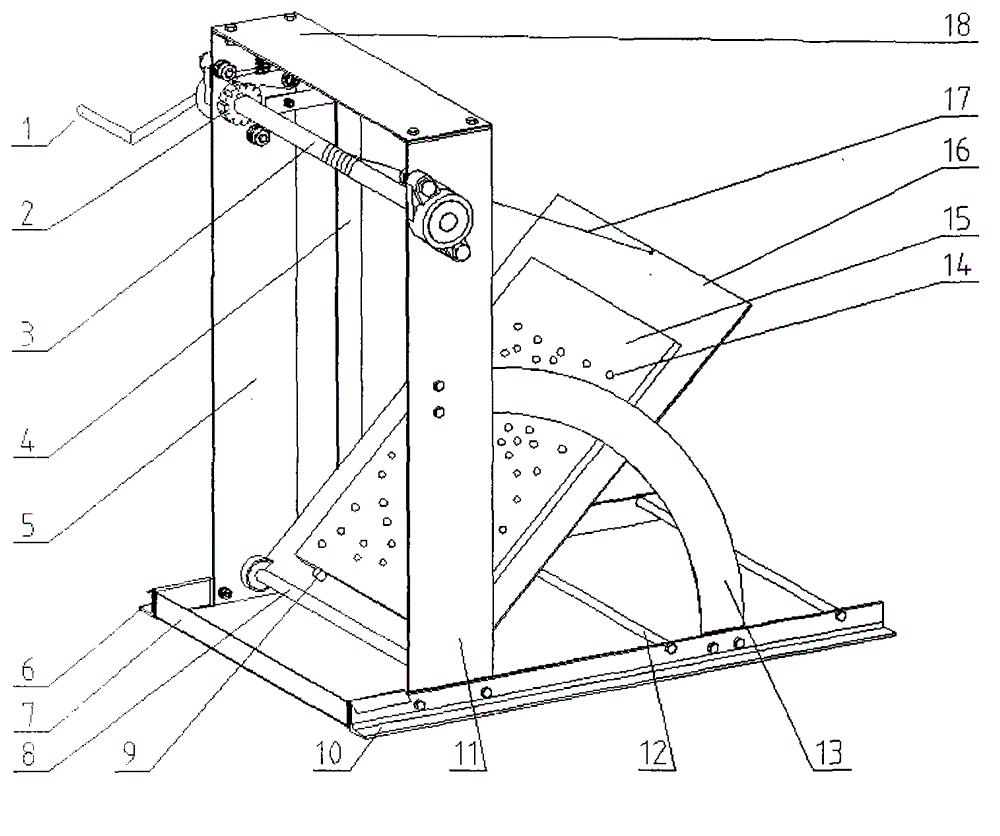

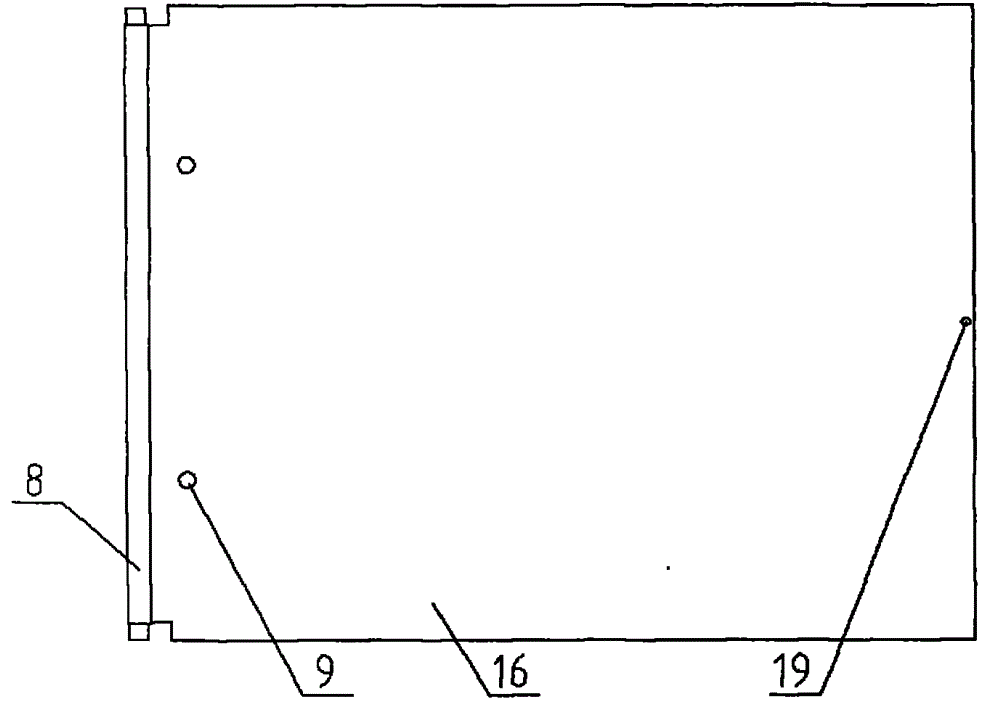

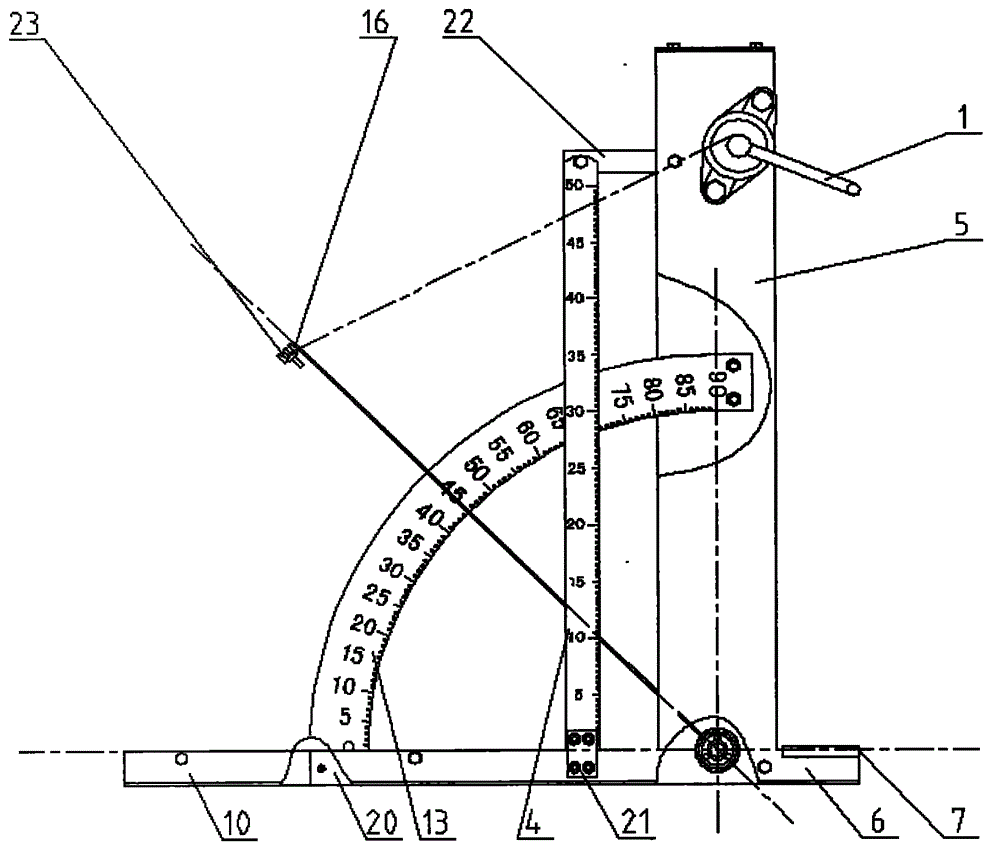

[0033] The three-dimensional schematic diagram of the inclinometer device is as follows figure 1 As shown, an inclinometer device that can place plates of different materials and adjust and lock the included angle with the horizontal plane can realize the measurement of the friction angle and friction coefficient of bulk materials on different materials. The side where the rocker 1 is located is the operating end of the device, which is characterized in that the operating end side beam 6 and the non-operating end side beam 10 are connected by two support rods 12 with bolts to form an inclinometer base; operating end side plate The lower ends of 5 and the non-operating end side plate 11 are respectively fixed to the operating end side beam 6 and the non-operating end side beam 10 with bolts, the upper end is bent and bolted through the top plate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com