pendulum friction wall

A pendulum type, friction plate technology, applied in building components, anti-vibration and other directions, can solve the problems of high surface pressure, unfavorable building function segmentation, auxiliary material wear and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

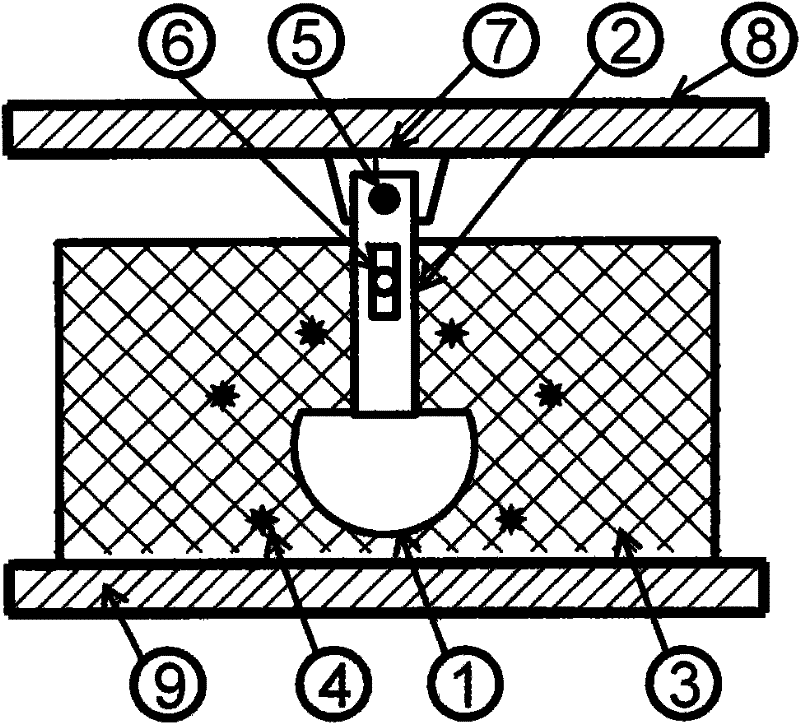

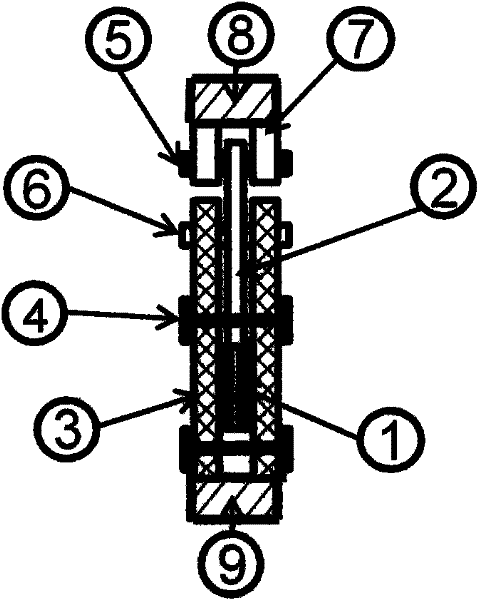

[0021] figure 1 , figure 2 It is the specific structure schematic diagram of this embodiment. The present embodiment is made up of friction plate 1, swing arm 2, lightweight wall body 3, pull bolt 4, hinge shaft 5, chute shaft 6, connecting plate 7, upper beam 8, and lower beam 9. The lower beam 9 and the upper beam 8 can be made of channel steel or I-beam, and are firmly connected to the roof and floor of the structure. The connecting plate 7 is welded on the upper crossbeam 8 and is a member of the connecting structure and the friction pendulum. In actual operation, the connecting plate 7 and the upper crossbeam 8 can also be combined into one. The friction pendulum is composed of a swing arm 2 and a friction plate 1, connected together with a connecting plate 7 through a hinge shaft 5, and can freely rotate around the hinge shaft. A rectangular chute is opened on the swing arm 2, and the chute shaft 6 is fixed on the light wall 3, and the swing arm 2 transmits horizonta...

Embodiment 2

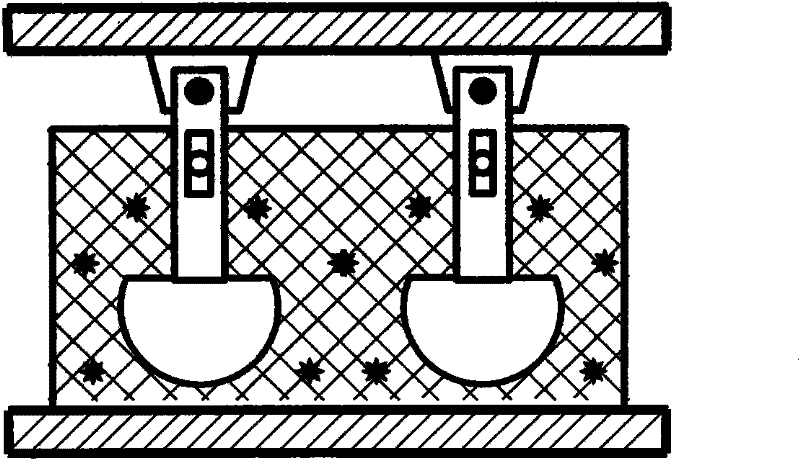

[0023] image 3 It is the specific structure schematic diagram of this embodiment. Several friction pendulums can be arranged in one friction wall. Other structures are basically the same as in Embodiment 1.

Embodiment 3

[0025] Figure 4 with Figure 5 It is the specific structure schematic diagram of this embodiment. In this embodiment, multiple pendulums are placed in parallel, which is applicable to the situation where the building space is limited but greater damping is required. Other structures are basically the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com