Drive pulleys

A technology for driving pulleys and pulleys, applied in electric components, engine components, machines/engines, etc., can solve the problems of low overall work efficiency, waste of energy by cooling pumps, etc., and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

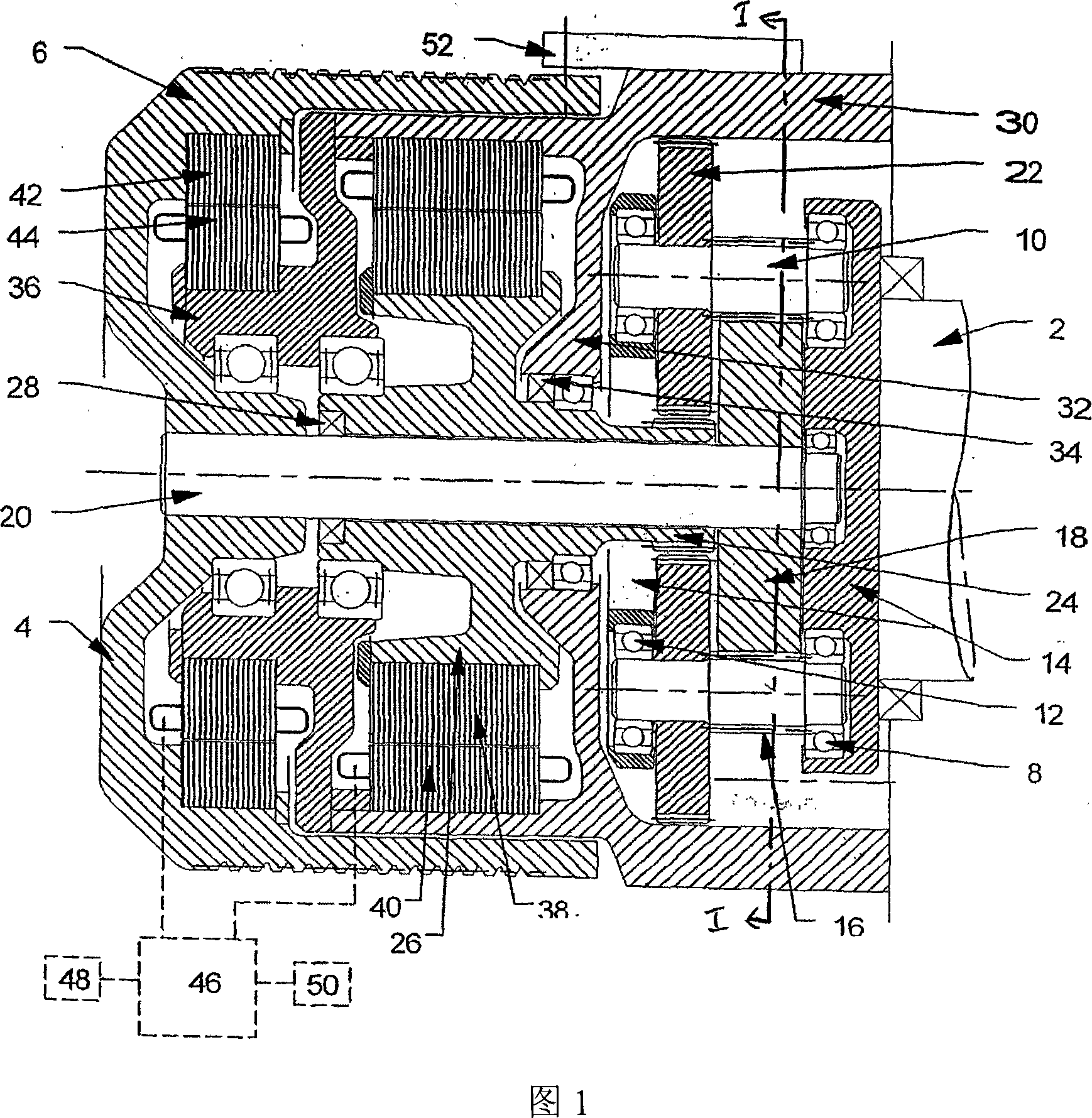

[0021] The pulley shown in the drawing is shown connected to the crankshaft 2 of the engine. The crankshaft 2 is connected to the input of a transmission system comprising a planetary gear set, the output of which is connected to a generally cup-shaped hollow cylindrical member 4 having a plurality of V-shaped grooves on its outer surface of circular cross-section, And constitute the belt mating surface 6 of the multi-V pulley.

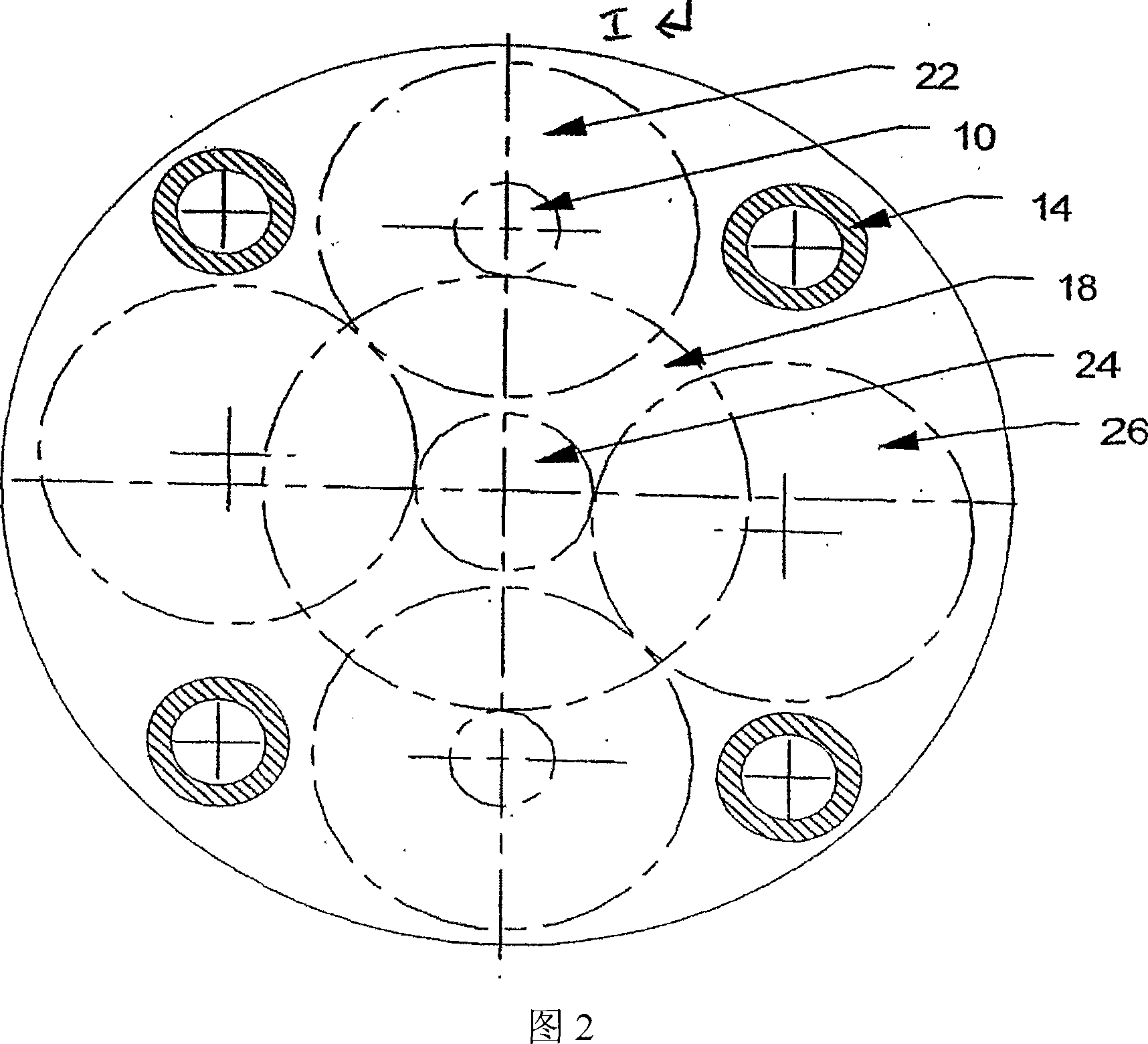

[0022] More specifically, the input consists of two ball bearings 8 supported by annular rings and connected together. The ball bearings 8 accommodate one end of a respective planetary shaft 10 of the planetary gearset, the other end of which is accommodated in a respective further ball bearing 12 . The two ball bearings 12 are supported and connected together by another annular ring. The two annular rings are connected together by four posts, which are only visible in Figure 2. The two annular rings and the four posts together form the carrier 14 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com