Speed changing device capable of adjusting feeding length

A technology of feeding length and speed change device, which is applied to transmission devices, belts/chains/gears, mechanical equipment, etc., and can solve problems such as equipment damage, complex structure, and product quality degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

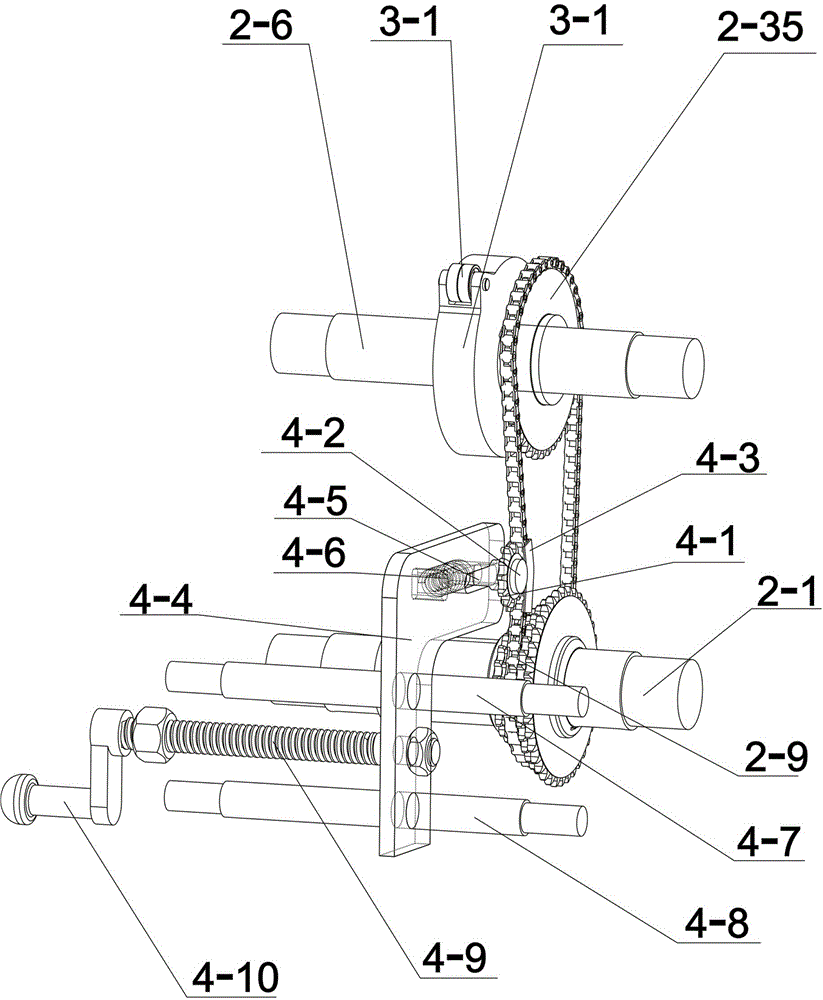

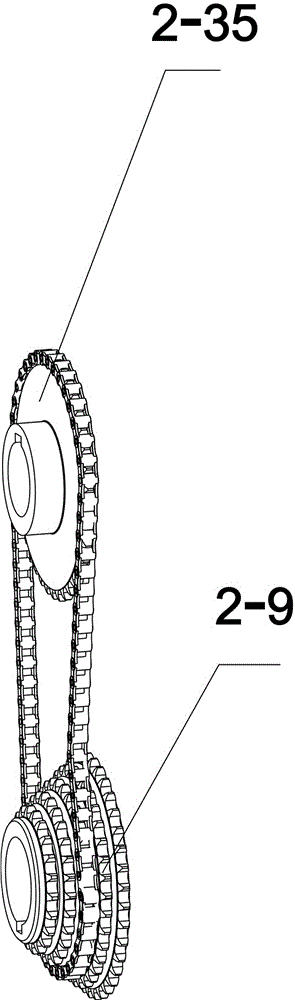

[0015] Such as figure 1 , figure 2 As shown, a speed change device that can adjust the feeding length includes a cam transmission shaft 2-6, a power shaft 2-1, and a sliding shaft 4-2, and the cam transmission shaft 2-6 and the power shaft 2-1 are all installed on the frame superior. The variable speed sprocket 2-35 is installed on the cam drive shaft 2-6, the multistage variable speed sprocket 2-9 is installed on the power shaft 2-1, and the adjusting sprocket 4-1 is installed on the slide shaft 4-2. The sliding shaft 4-2 is installed on the control panel 4-4, the sliding shaft 4-2 is connected with one end of the compression spring 4-6, and the other end of the compression spring 4-6 is fixed on the control panel 4-4. One end of the adjusting screw 4-9 is fixed on the control panel 4-4, and the other end of the adjusting screw 4-9 is equipped with an L-shaped rocking handle 4-10. The control panel 4-4 is equipped with a sprocket groove 4-3, and the adjustment sprocket 4-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com