Variable ratio rack and power steering gear

A rack and gear technology, applied in the field of power steering gear, can solve problems such as steering sticking and uneven transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

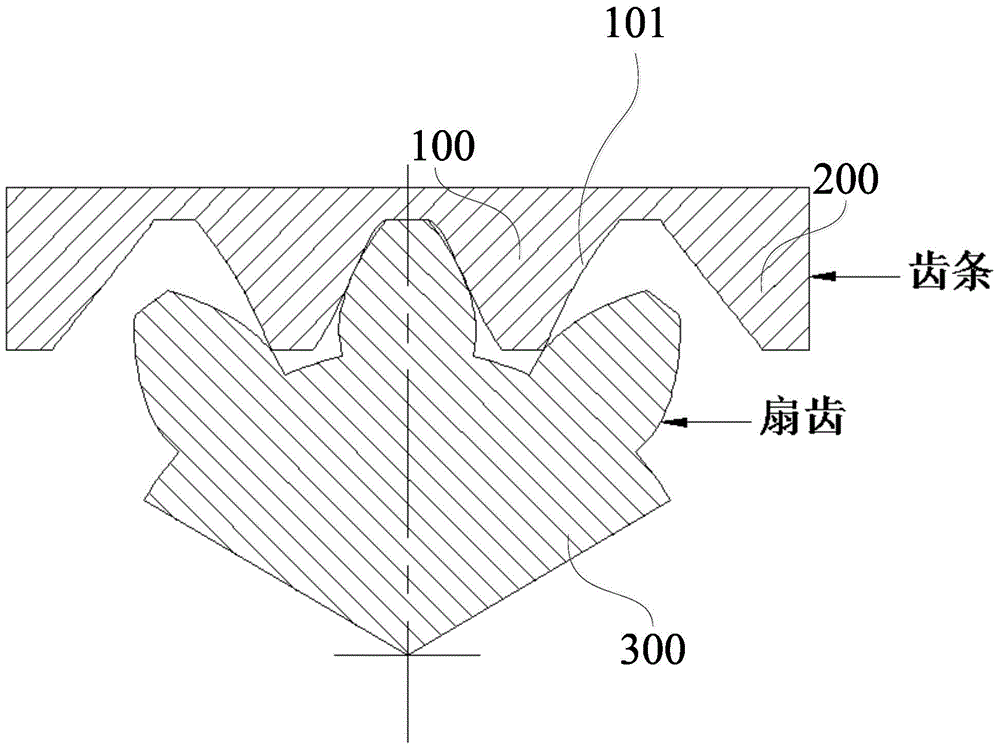

[0033] A variable ratio rack, such as Figure 1-5 As shown, at least gear tooth I100 and gear tooth II200 adjacent to gear tooth I100 are included.

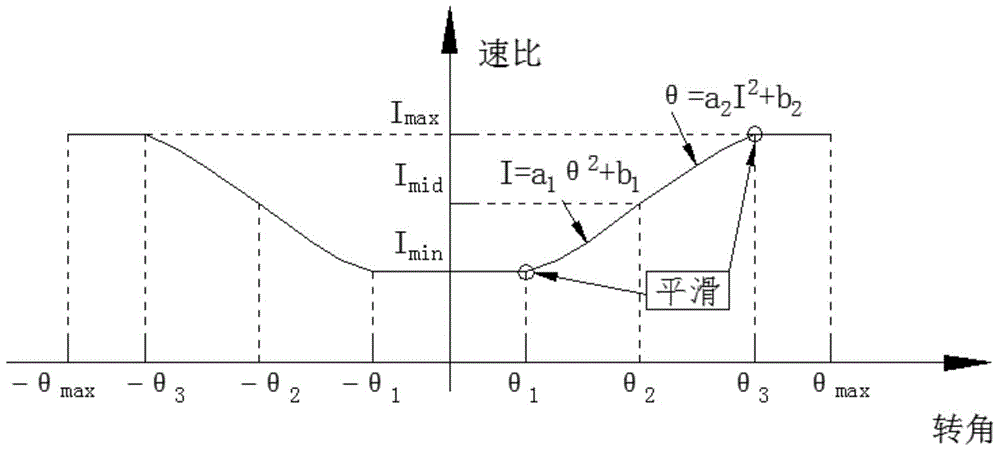

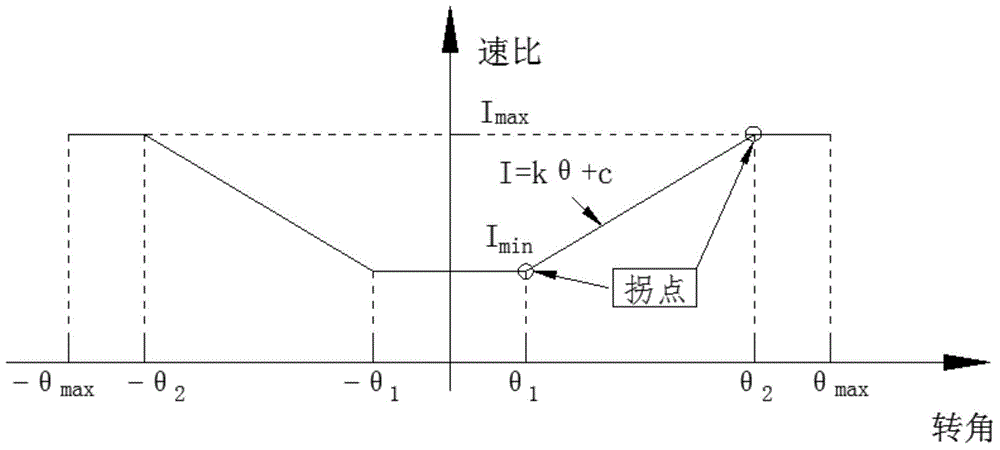

[0034] Such as figure 2 As shown, the gear teeth I100 and gear teeth II200 and the gears 300 meshed with them have different transmission speed ratios I min , I max The gear teeth I100 and the gear teeth II200 of the variable ratio rack have different tooth surface shapes, and after meshing with the gear teeth on the gear 300, they pass through the gear teeth I100 and After the gear teeth II200, the transmission speed ratio I is changed from I min smoothly transitions to I max , to realize the function of variable ratio.

[0035] In order to achieve the above function of smoothly changing the transmission speed ratio, the tooth surface 101 of the gear tooth I100 close to the gear tooth II200 has a structure so that the variable ratio rack and the gear 300 can be in the change range of the transmission speed ratio {I min ,...

Embodiment 2

[0050] A power steering gear is equipped with the power steering gear using the variable ratio rack described in Embodiment 1 and the gear matched with it.

[0051] As a preference, the power steering gear is a recirculating ball power steering gear.

[0052] Further experiments show that the power steering gear described in this embodiment, including the recirculating ball power steering gear, has extremely stable transmission and smooth speed change. Compared with the tooth surface shape obtained by other curves, it has the advantages of stable transmission and smooth steering.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com