Multi-stage transmission vehicle safety tensioning device

A technology for automobile safety and tensioning devices, which is applied to motor vehicles, bicycle accessories, transportation and packaging, etc., and can solve the problems of long device size, inconvenient carrying, transportation and operation, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

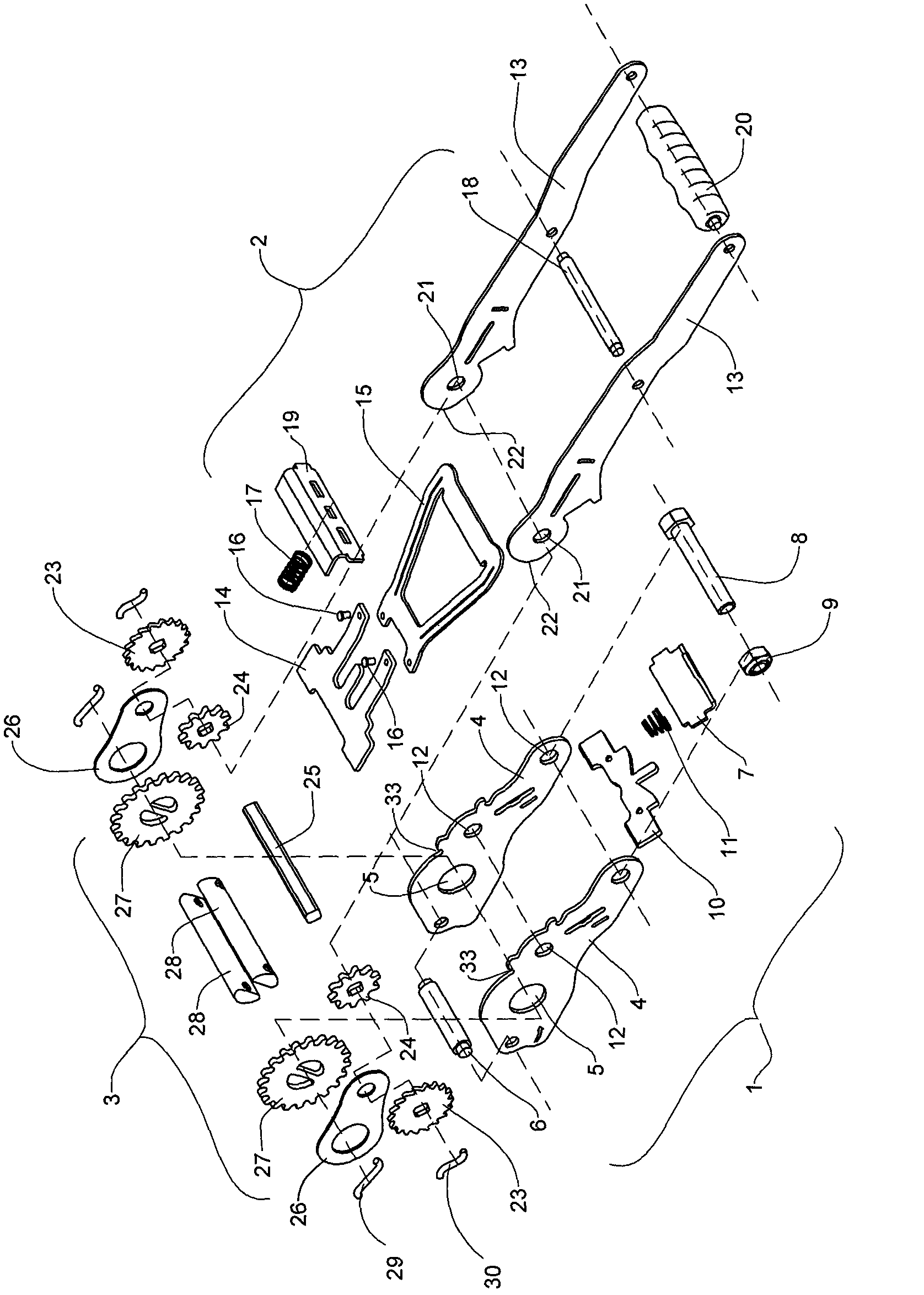

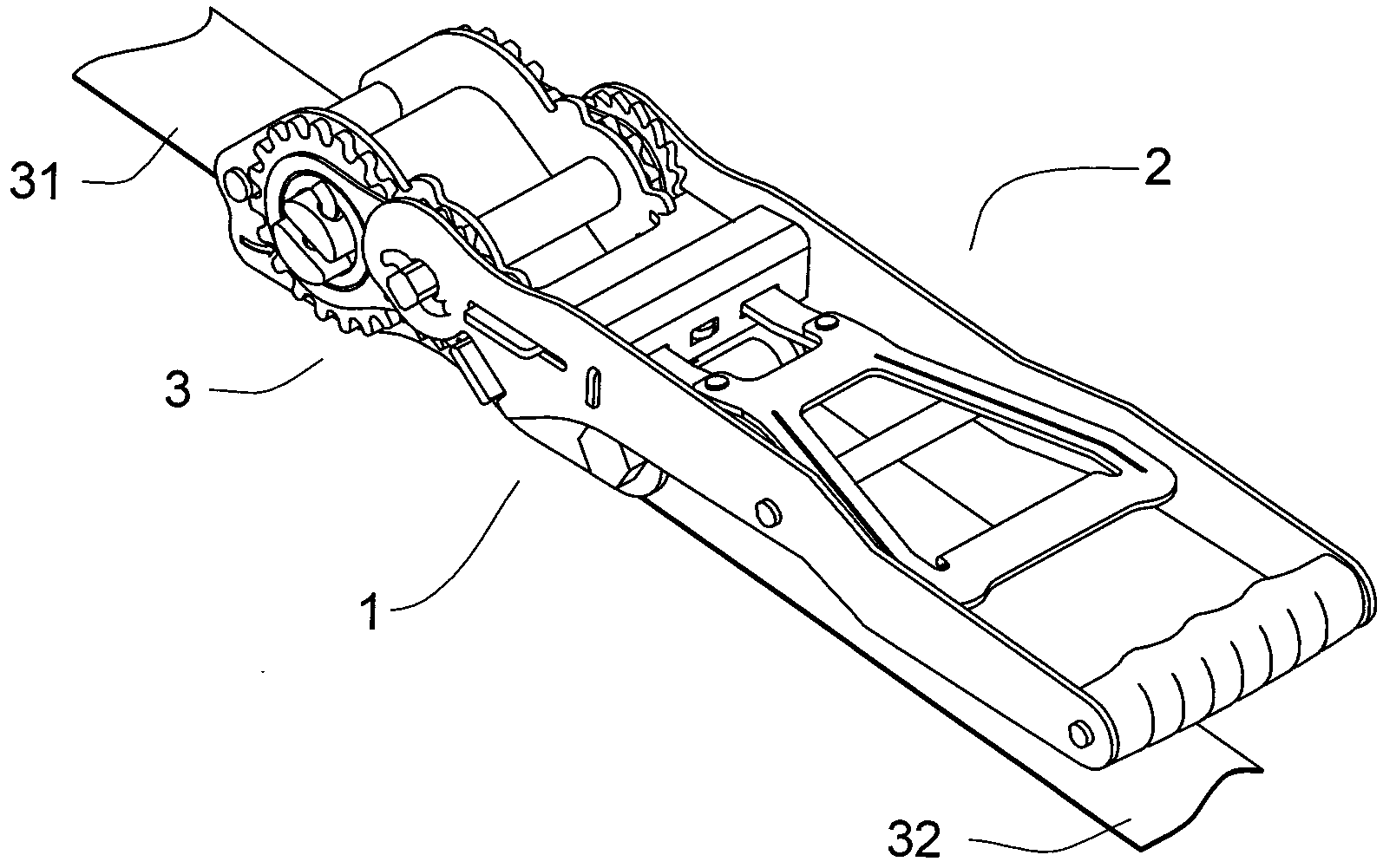

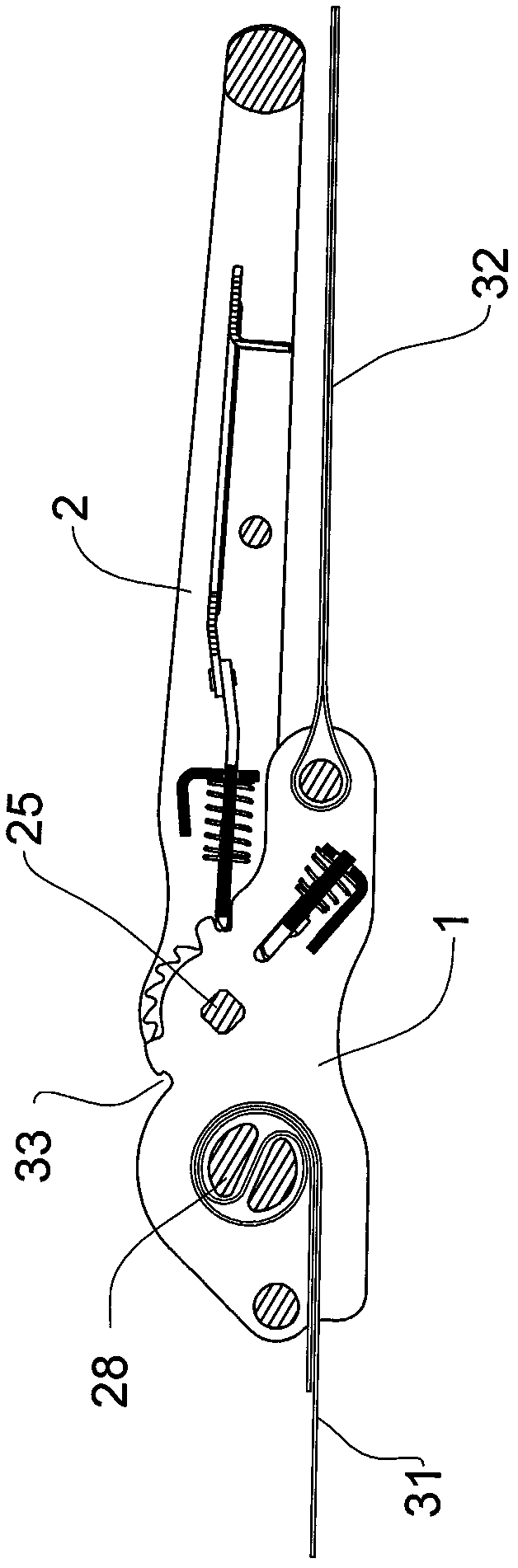

[0027] Such as figure 1 , 2 , 3, 4, and 5 show the car safety tensioning device, including a base assembly 1, a handle assembly 2, and a multi-stage transmission assembly 3, wherein:

[0028] The base assembly 1 includes a base, a stop pawl 10, a stop pawl spring 11, etc., wherein the base is formed by connecting two base side pieces 4 of the same structure through the base fixing piece 7 and the base fixing shaft 6 (the two The base side panels form the base side walls described in claim 4). Except being provided with the hole that is used to install fixed plate 7 and fixed shaft 6 on two base side pieces 4, also be provided with the hole that is used to install main rotating shaft 28, stop ratchet 10 and a plurality of transmission shafts. In addition, the upper edges of the two base side panels 4 are undulating concave-convex shapes, and form a release groove 33 for the active pawl 14 to be caught. The base fixed piece 7 and the stop ratchet 10 are respectively inserted ...

Embodiment 2

[0038] Different from Embodiment 1, the multi-stage transmission assembly adopts a multi-stage transmission mechanism with more than one stage and two stages, and more transmission pairs can be added between the first stage transmission and the final stage transmission as required. Specifically, it can be implemented as follows: the transmission shaft in the first embodiment is used as a primary transmission shaft, the device on the transmission shaft is connected to the ratchet and the driving gear, and the driving gear meshes with the gear on the next transmission shaft. And the main rotating shaft is as the last stage transmission shaft, is fixed with the passive gear that meshes with the gear on the last stage transmission shaft on it. The required binding force can be obtained by adding the second, third or more transmission gear sets between the first-stage and the last-stage transmission. The transmission shaft of the middle stage is between the transmission shaft of th...

Embodiment 3

[0039] Embodiment three: as Figure 9 Shown, different from previous two embodiments is not needing ratchet, but directly uses driving gear as ratchet (that is, the transmission wheel in claim 1 is this driving gear), driving pawl and stop pawl are directly connected with The driving gear is in contact, and the ratchet is omitted to achieve the same function. In this embodiment, the driving gear, the driving ratchet and the stop ratchet are changed adaptively, and the rest of the structure is basically the same as the previous embodiment, so it will not be described in detail.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com