Modularized full-meshed brake type transmission

A transmission and full-mesh technology, applied in transmission, gear transmission, transmission control, etc., can solve problems such as low transmission efficiency and increased fuel consumption, and achieve the effect of compact structure, good structural rigidity, and easy maintenance and analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

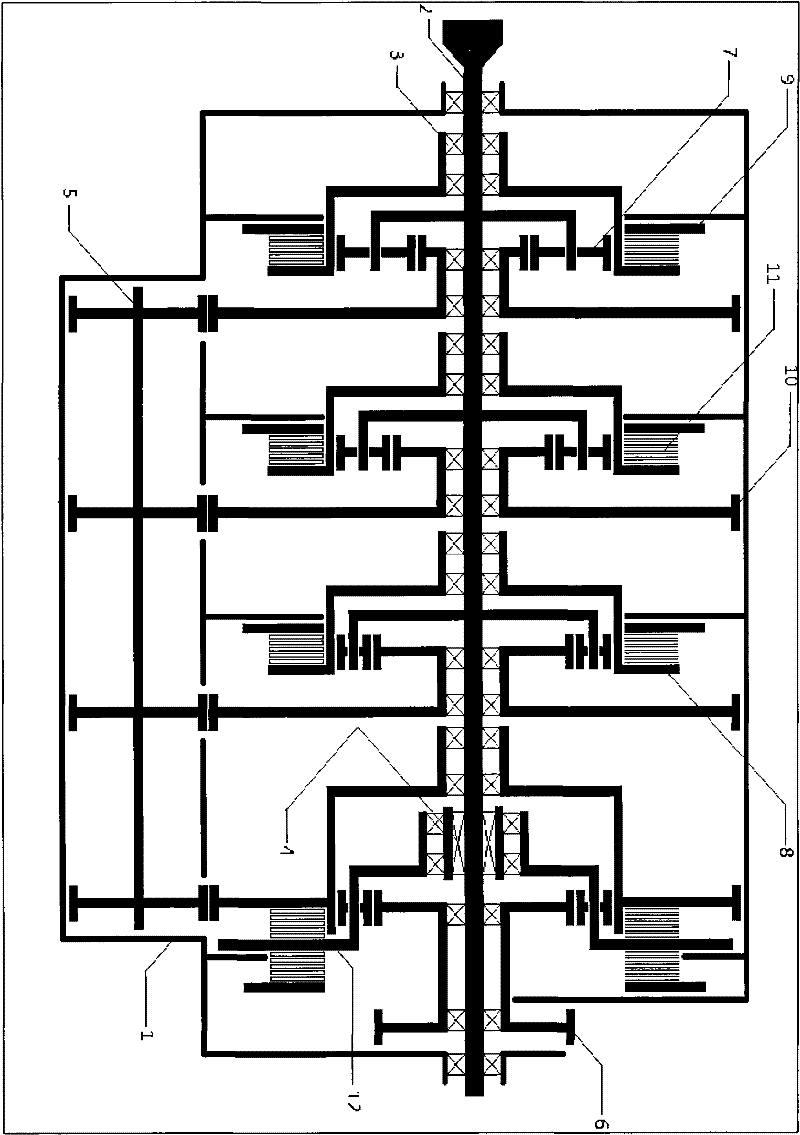

[0014] exist figure 1 Among them, the transmission shaft (3) is integrated with the planet carrier of each gear planetary gear train. Planetary gears (7) are housed on the planet carrier of each gear position planetary gear train. The planetary gear (7) meshes with the sun gear (10) and the ring gear (8) simultaneously. The ring gear (8) can be kept locked with the transmission case under the braking of the brake (9). When the brake (9) is released, the ring gear (8) is not connected with other parts. The sun gear of each stage of the planetary gear train meshes with the carrier gear shaft assembly (5).

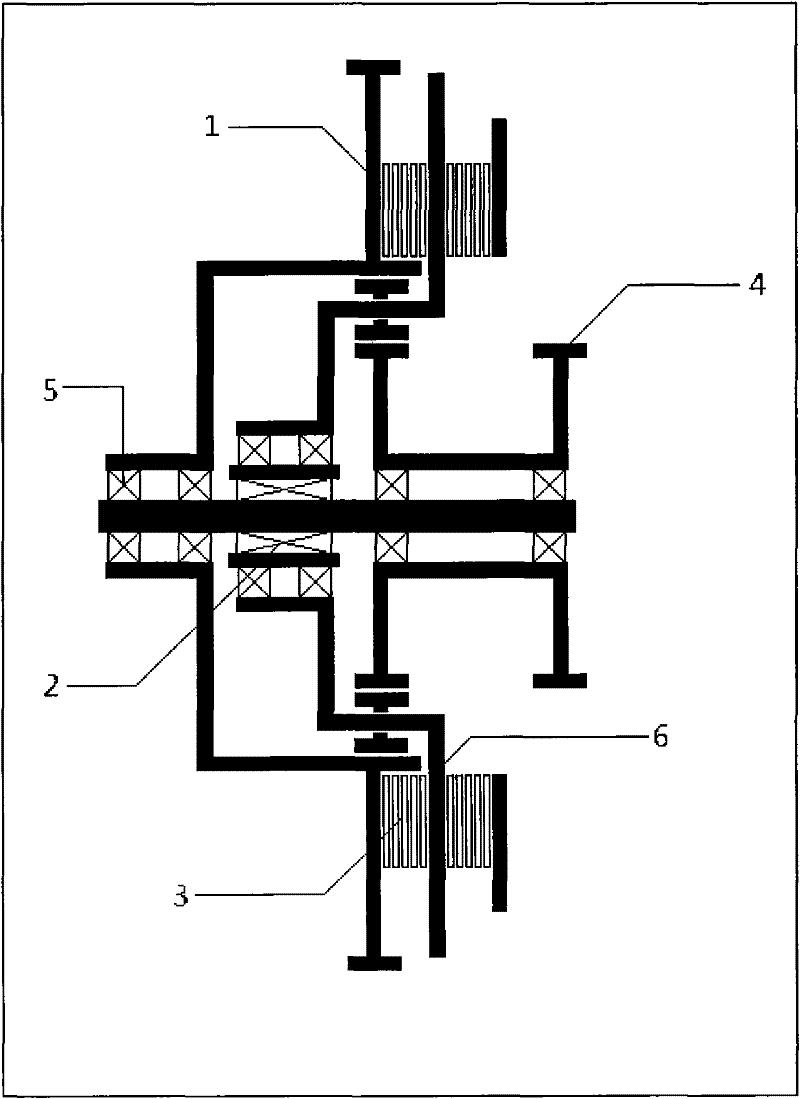

[0015] exist figure 2 Among them, the planet carrier (6) installed on the shaft through the sliding spline sleeve (2) can slide left and right. The left and right positions respectively correspond to two kinds of motion situations: when the planetary carrier (6) is on the left side, it is locked with the ring gear (1); when the planetary carrier (6) is on the right side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com