A planetary gear stepless transmission

A continuously variable transmission, planetary gear technology, applied in the direction of gear transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of poor fuel economy, low transmission efficiency, small transmission torque, etc., and achieve higher fuel economy. The effect of high stability, large transmission torque and large load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

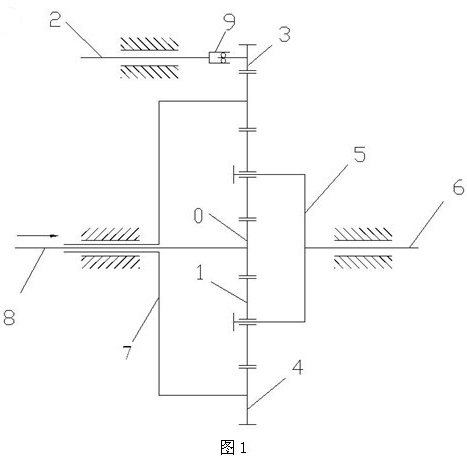

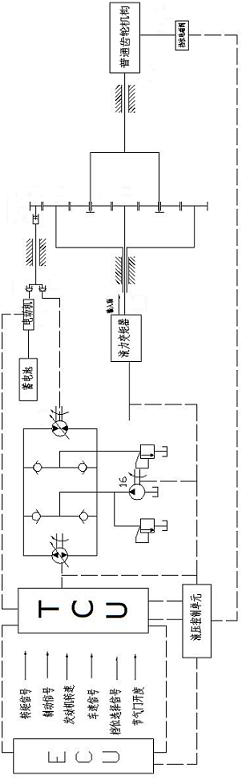

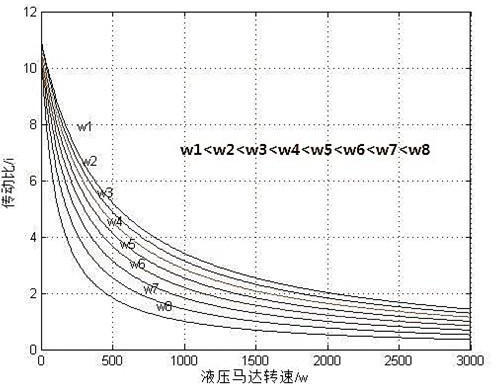

[0043] The planetary gear continuously variable transmission of the present invention includes a planetary gear continuously variable transmission, and the planetary gear continuously variable transmission includes a first input shaft 2, a second input shaft 8, a one-way clutch 9, a gear 3, and a planetary ring gear 4 , planetary gear 1, first planetary carrier 7, sun gear 0, second planetary carrier 5 and output shaft 6, the power of the planetary gear stepless transmission through the first input shaft 2 and the second input shaft 8 two degrees of freedom input to realize the function of stepless speed change; the second input shaft 8 is in line with the output shaft 6, the second input shaft 8 is just connected with the sun gear 0, the sun gear 0 meshes with the planetary gear 1, and the second input shaft 8 is in mesh with the planetary gear 1. The turntable arms of the two planetary carriers 5 pass through the shaft centers of the same number of planetary gears 1 and can r...

Embodiment 2

[0046] The planetary gear continuously variable transmission of the present invention includes a planetary gear continuously variable transmission, and the planetary gear continuously variable transmission includes a first input shaft 2, a second input shaft 8, a one-way clutch 9, a gear 3, and a planetary ring gear 4 , planetary gear 1, first planetary carrier 7, sun gear 0, second planetary carrier 5 and output shaft 6, the power of the planetary gear stepless transmission through the first input shaft 2 and the second input shaft 8 two degrees of freedom input to realize the function of stepless speed change; the second input shaft 8 is in line with the output shaft 6, the second input shaft 8 is just connected with the sun gear 0, the sun gear 0 meshes with the planetary gear 1, and the second input shaft 8 is in mesh with the planetary gear 1. The turntable arms of the two planetary carriers 5 pass through the shaft centers of the same number of planetary gears 1 and can r...

Embodiment 3

[0049] The planetary gear continuously variable transmission of the present invention includes a planetary gear continuously variable transmission, and the planetary gear continuously variable transmission includes a first input shaft 2, a second input shaft 8, a one-way clutch 9, a gear 3, and a planetary ring gear 4 , planetary gear 1, first planetary carrier 7, sun gear 0, second planetary carrier 5 and output shaft 6, the power of the planetary gear stepless transmission through the first input shaft 2 and the second input shaft 8 two degrees of freedom input to realize the function of stepless speed change; the second input shaft 8 is in line with the output shaft 6, the second input shaft 8 is just connected with the sun gear 0, the sun gear 0 meshes with the planetary gear 1, and the second input shaft 8 is in mesh with the planetary gear 1. The turntable arms of the two planetary carriers 5 pass through the shaft centers of the same number of planetary gears 1 and can r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com