Four branch differential transmission systems.

A differential transmission and transmission system technology, applied in the direction of differential transmission, transmission, transmission components, etc., can solve the problem of not being able to obtain the Ro ratio, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

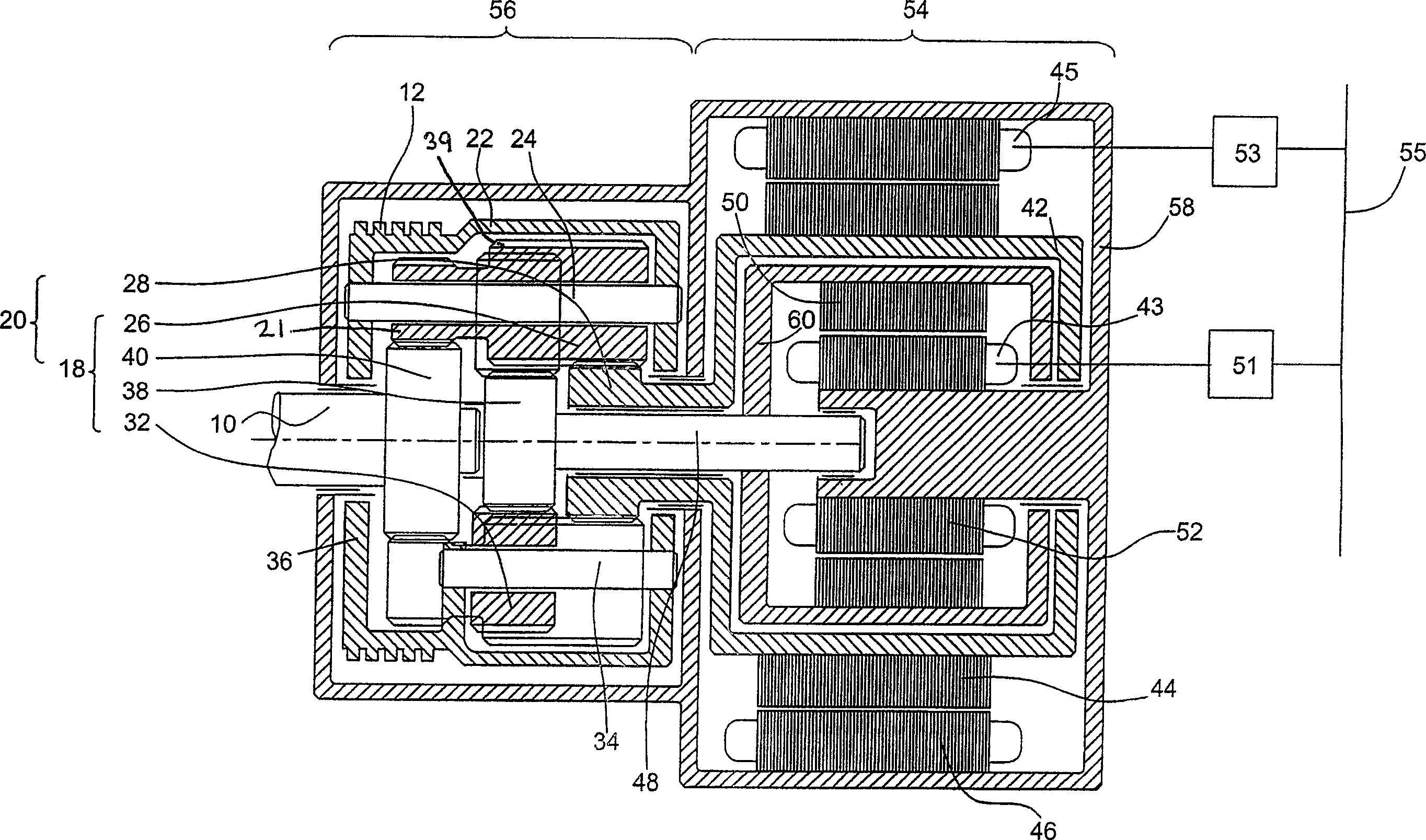

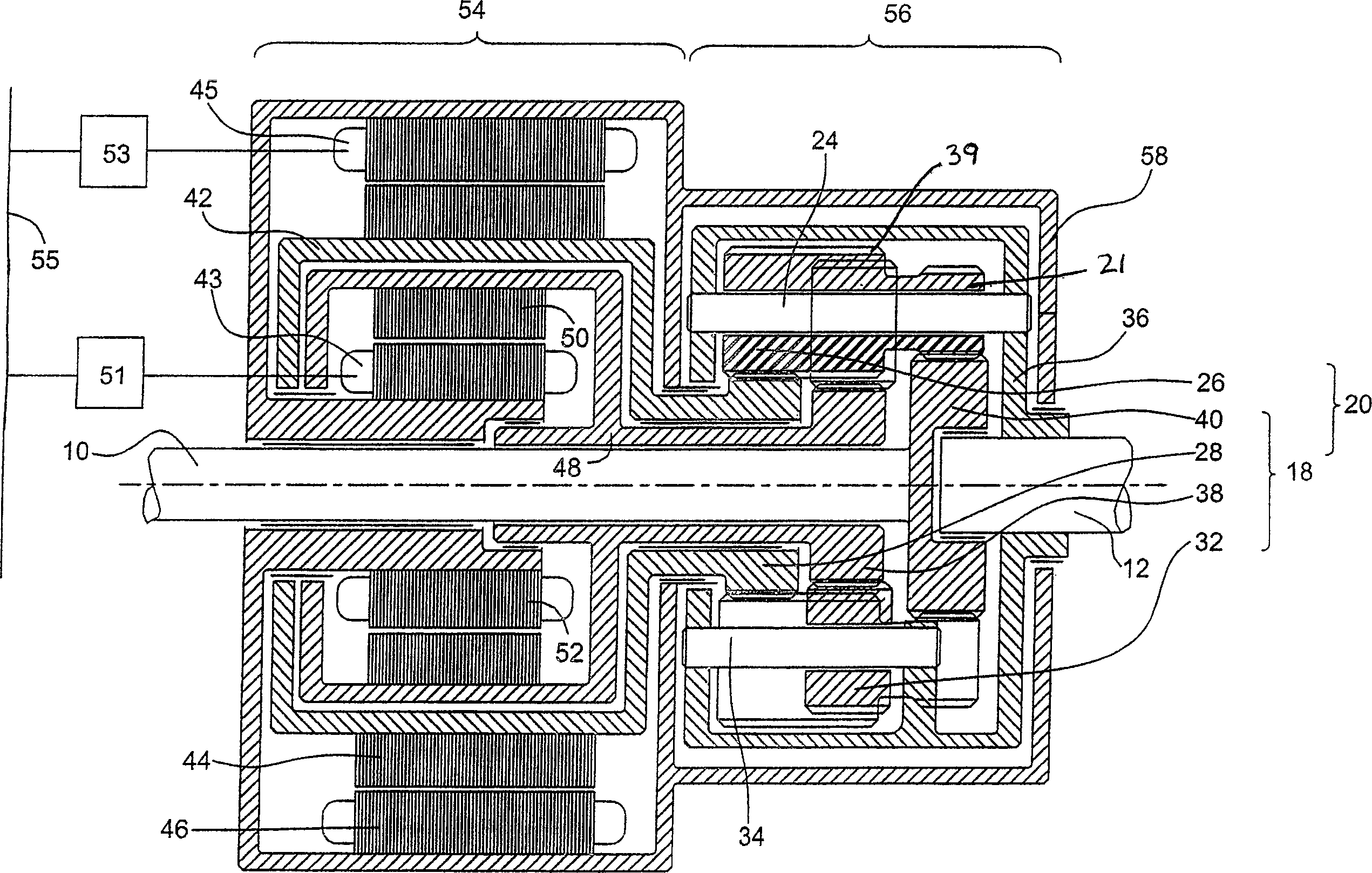

[0028] figure 1 The FBD shown in has an input shaft (first leg) 10 and an output shaft (second leg) 12 formed by a common planetary carrier 22 . The input and output can essentially be swapped so that the same node ratios (discussed below) are produced rather than different branch speed ratios. In this example, the input shaft is connected to the engine flywheel. The engine flywheel has a transverse drive output, which is most common in front wheel drive motor vehicles, but the axle frame 22 can also form an output member in the form of a gear or sprocket which leads the drive to a transversely arranged horizontal shaft.

[0029] The FBD also includes a so-called inverse planetary gear set 18 , and another so-called spur gear set 20 . Both gear sets have no ring gears, but consist only of straight or helical spur gears, which allow for a more compact design.

[0030]The reverse gear set 18 includes a sun gear 40 driven by the input shaft 10 , which meshes with a set of plan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com