Drivetrain with engine, transmission, planetary gear set and electric machine

A planetary gear set and drive train technology, applied in the drive train field, can solve problems such as high weight installation space, achieve the effect of simplifying disassembly and maintenance, and improving accessibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

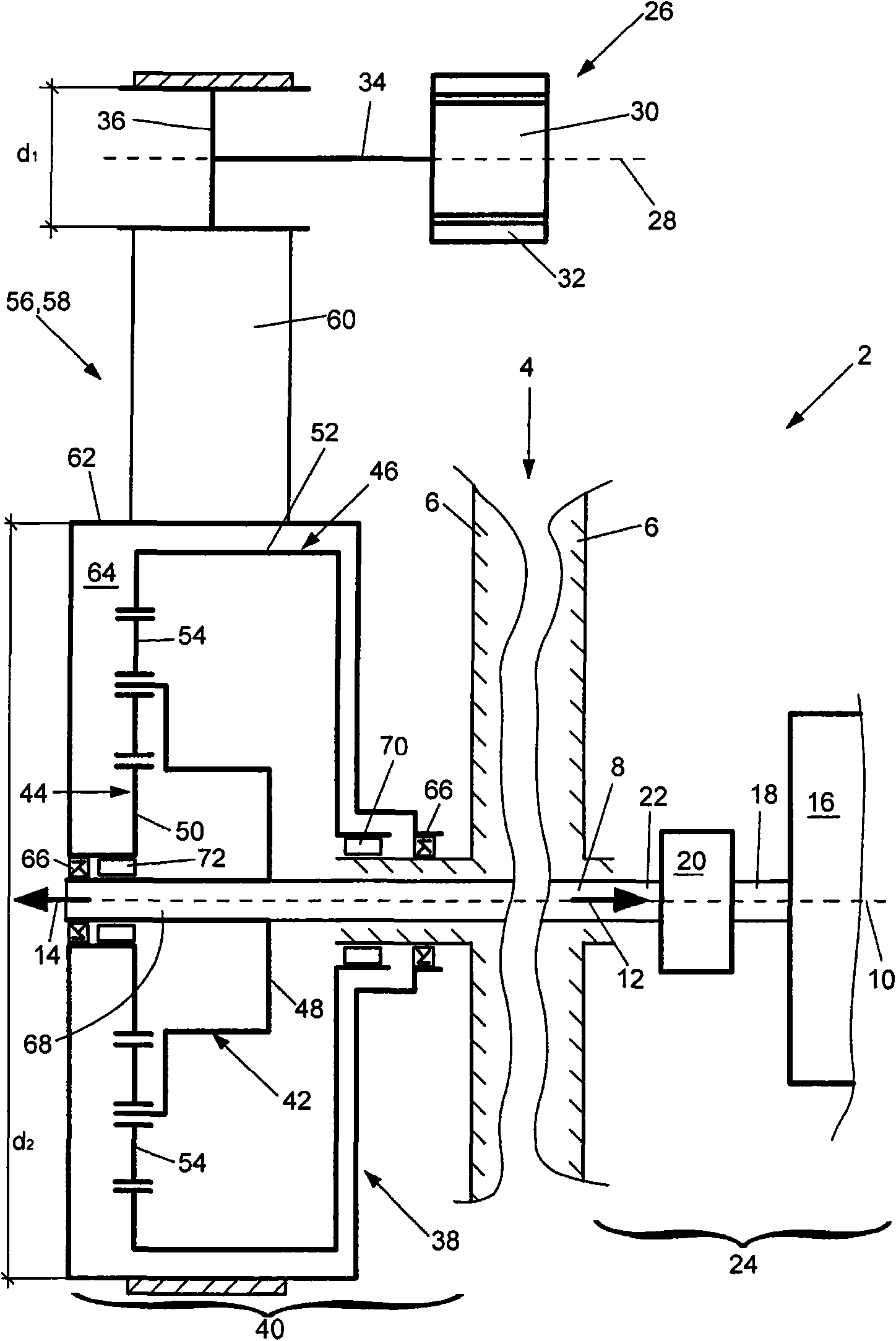

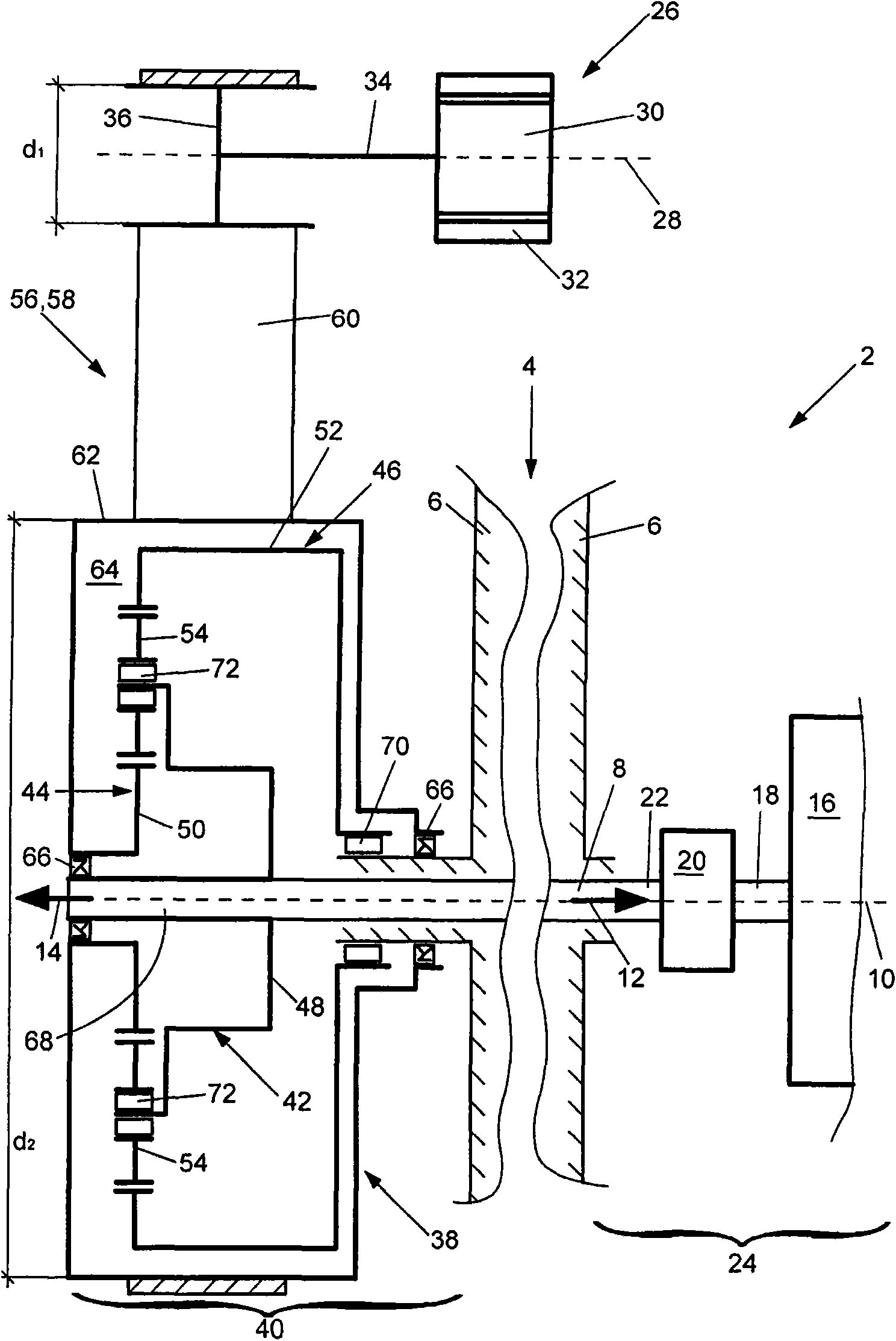

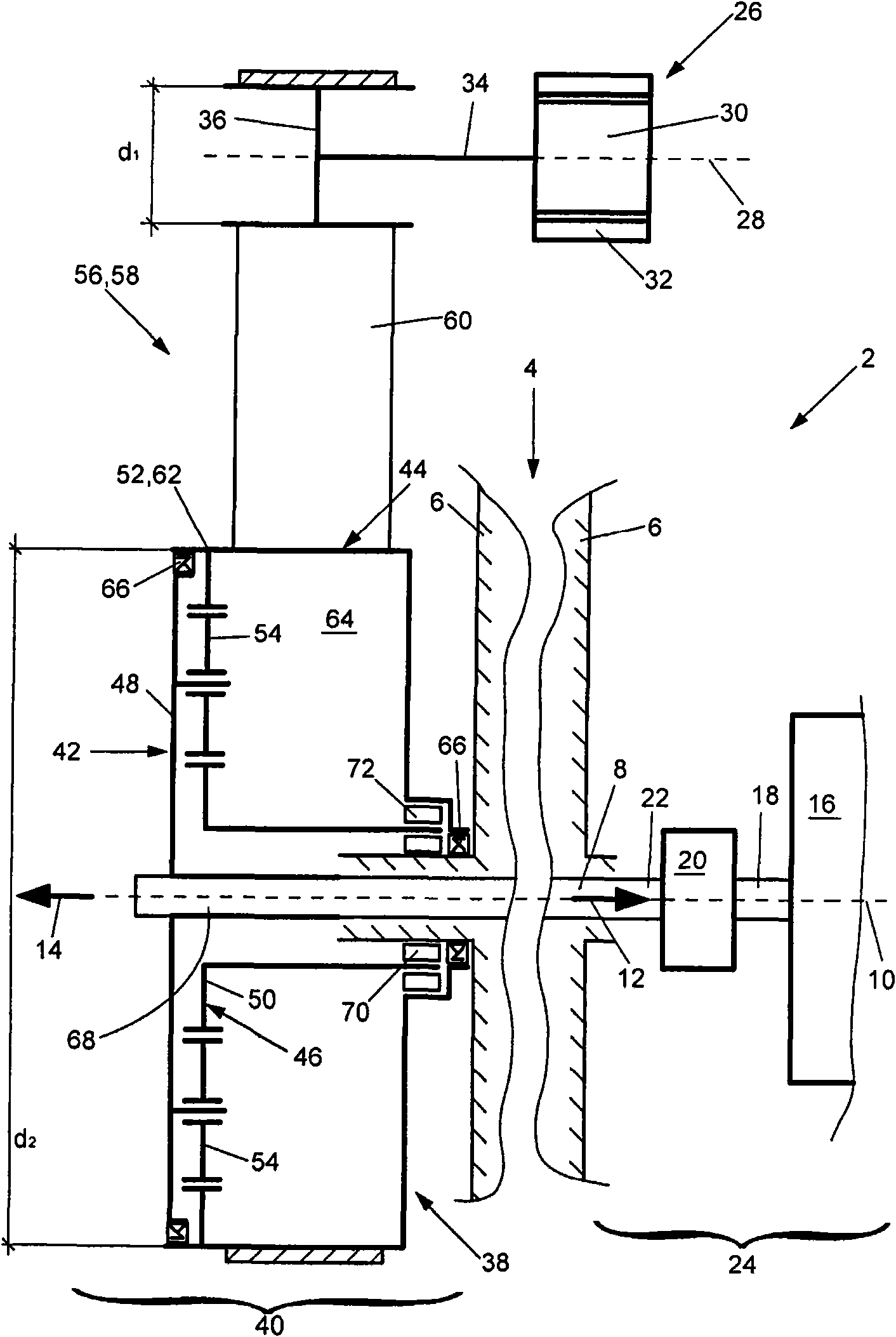

[0053] figure 1 A first embodiment of a drive train 2 for a motor vehicle according to the invention is shown. The drive train 2 has an engine 4 which in the present case is designed as an internal combustion engine. figure 1 Only a motor housing 6 of the motor 4 and a drivable motor shaft 8 are shown. The motor shaft 8 , which is rotatable about a rotational axis 10 , extends on one side in a first axial direction 12 and on the other side in a second axial direction 14 opposite to the first axial direction 12 .

[0054] The drive train 2 also includes a transmission 16, which is only figure 1 is schematically indicated. The transmission 16 has a transmission input shaft 18 which is in rotational driving connection with a first end 22 of the motor shaft 8 via a connection arrangement 20 indicated only schematically, wherein the first end 22 of the motor shaft 8 points towards the first Axial direction 12. The transmission 16 and / or the connection arrangement 20 are arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com