Torque transmission structure, traction drive transmission device, and steering device for vehicle

A speed change device, traction transmission technology, applied in the direction of transmission device, friction transmission device, belt/chain/gear, etc., can solve the problems that cannot be realized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

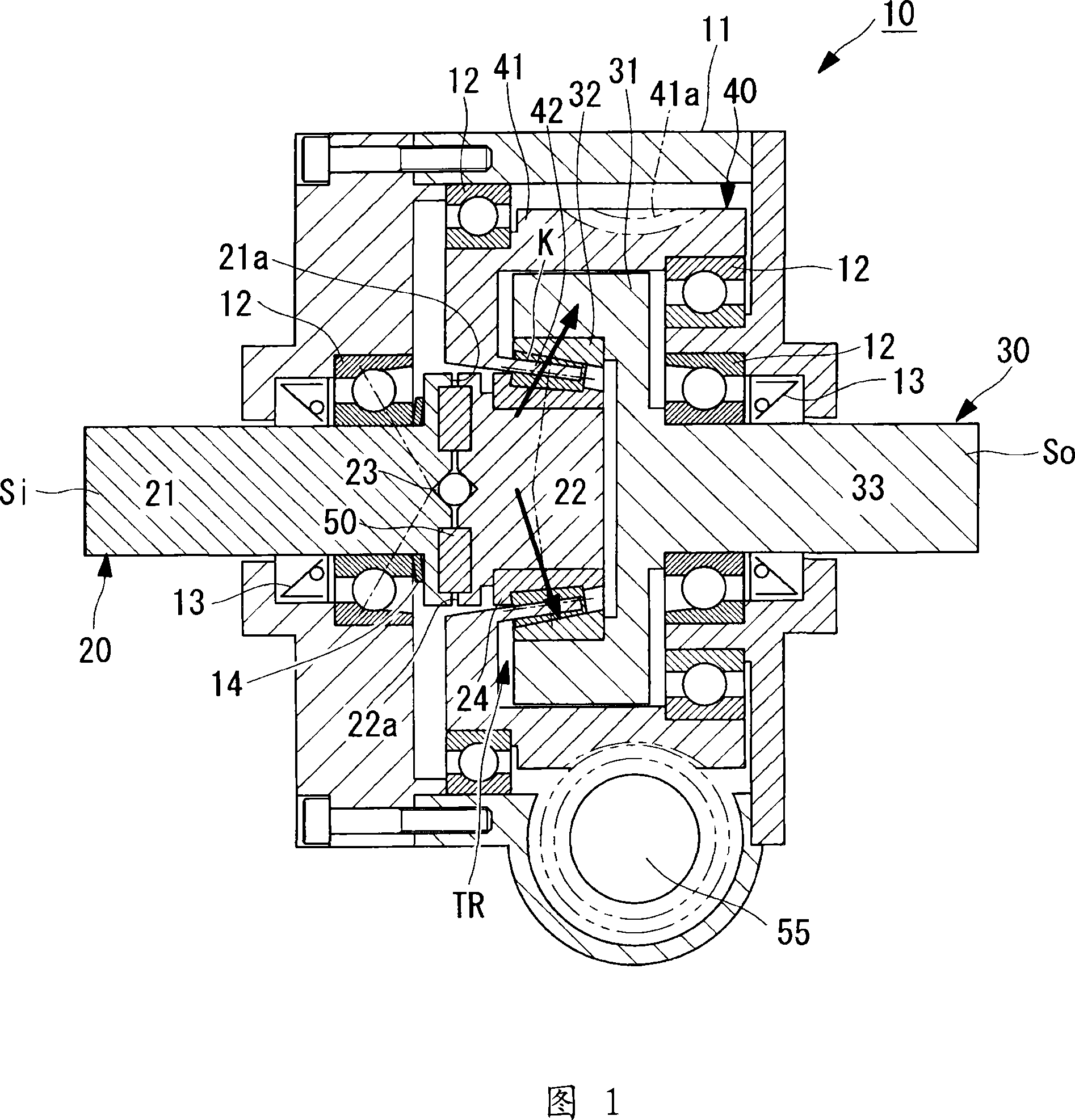

[0082] FIG. 1 is a cross-sectional view showing a first embodiment of a traction transmission transmission according to the present invention. This traction transmission transmission device (hereinafter referred to as "transmission device") 10 has the function of changing the rotational speed of the input shaft Si to a desired gear ratio by utilizing the traction of the rolling element K interposed between the input shaft Si and the output shaft So. Output function of the output shaft So.

[0083] The traction is a tangential force acting on a contact portion where a plurality of rolling elements K are arranged as a rotating body in a rolling-sliding state. A traction transmission mechanism TR is formed between the inner ring 20 having the input shaft Si and the outer ring 30 having the output shaft So. The traction transmission mechanism TR can transmit torque from the inner ring 20 to the outer ring 30 through the rolling elements K through the rheological characteristics o...

no. 2 approach

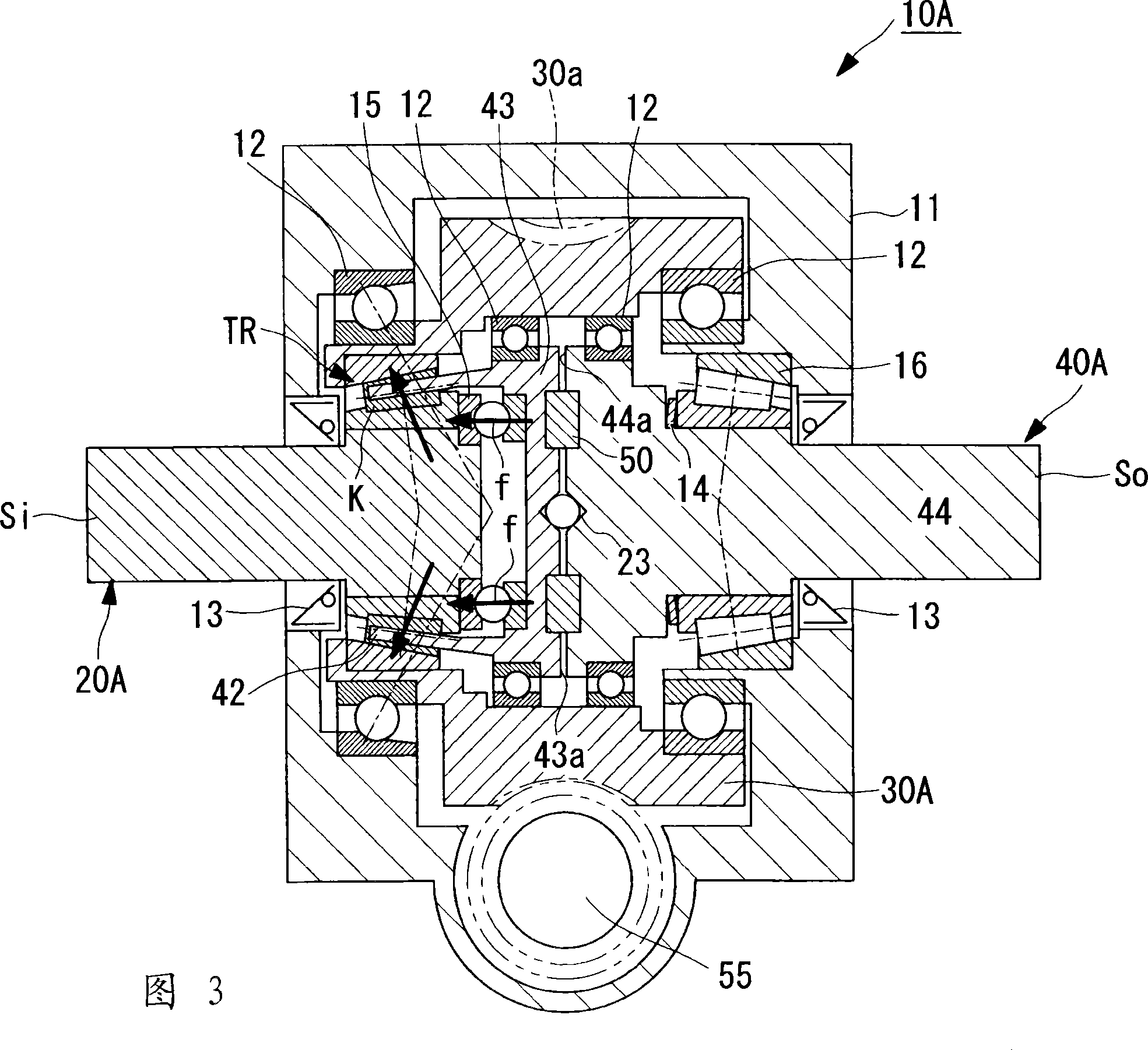

[0138] Next, a second embodiment of the transmission device of the present invention will be described based on the drawings. The embodiment described below connects the input and output of the above-mentioned two sets of traction drive speed changes to form a two-stage speed change in which a first-stage speed change and a second-stage reverse speed change are performed. In addition, the same code|symbol is attached|subjected to the same part as the above-mentioned embodiment, and detailed description is abbreviate|omitted.

[0139] The speed change device 10F of the embodiment shown in FIG. 8 uses the traction of the rolling element K interposed between the input shaft Si and the output shaft So to change the rotation speed of the input shaft Si to a desired gear ratio and output the output shaft from the output shaft So. , and the input shaft Si and the output shaft So are connected symmetrically to perform two-stage speed change.

[0140] The input shaft Si and the output...

no. 3 approach

[0182] Next, a third embodiment of the transmission device of the present invention will be described based on the drawings. The embodiment described below and the second embodiment have a two-stage transmission configuration in which the input and output of the above-mentioned traction transmission transmission are connected in a bilaterally symmetrical manner to perform a reverse speed change at the second stage with the same speed ratio. It is different, and constitutes a two-stage speed change that performs opposite speed changes with different speed ratios. In addition, the same code|symbol is attached|subjected to the same part as the above-mentioned embodiment, and detailed description is abbreviate|omitted.

[0183] The speed change device 10K of the embodiment shown in FIG. 13 uses the traction of the rolling element K interposed between the input shaft Si and the output shaft So to change the rotational speed of the input shaft Si to a desired gear ratio and output t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com