Motor stator coil winding machine

A technology of motor stator and winding machine, applied in the field of motor stator coil winding machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

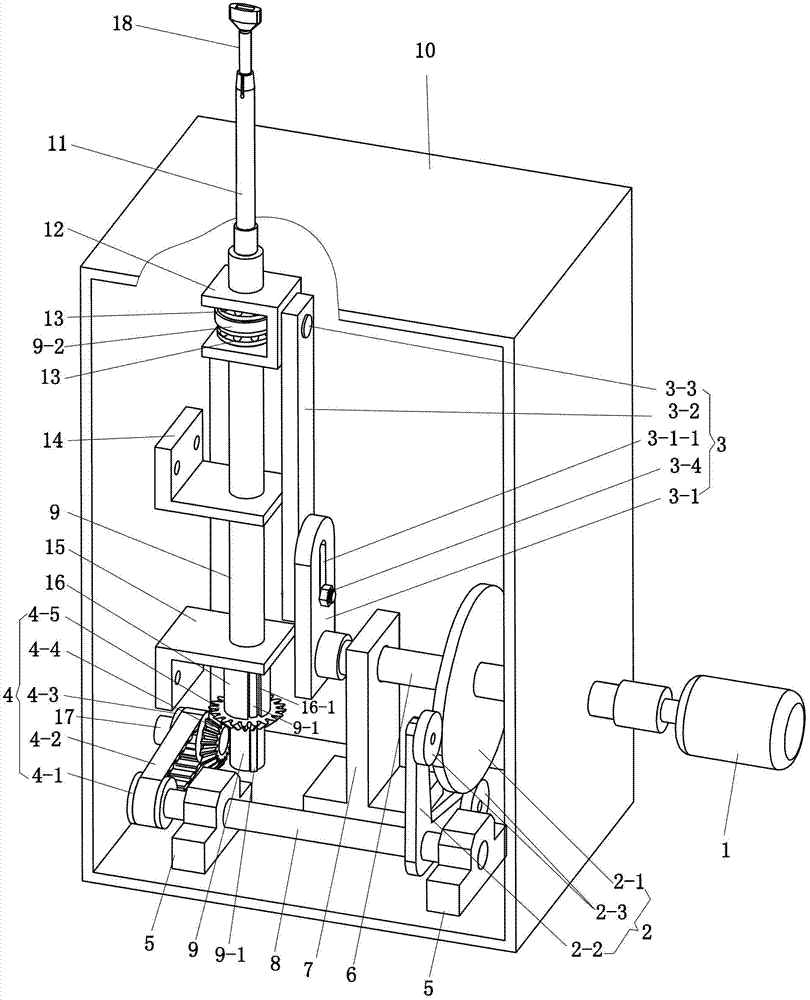

[0024] See figure 1 , The motor stator coil winding machine includes a casing 10, a drive motor 1, a power shaft 6, a main shaft 9, a long transmission shaft 8, and a short transmission shaft 17.

[0025] A support 7 and two supports 5 are fixed on the bottom plate of the box body 10, the power shaft 6 is supported by the side plate of the support 7 and the box body 10, and the transmission long axis 8 is supported by the two supports 5. An upper mount 14 and a lower mount 15 are fixed on the other side plate.

[0026] The cam mechanism 2 has a cam 2-1 fixed on the power shaft 6, an angular swing frame 2-2 fixed on the transmission long shaft 8, and rollers 2-3 are respectively hinged on the two ends of the swing frame 2-2. , The roller 2-3 rolls along the outer peripheral surface of the cam 2-1.

[0027] The middle part of the main shaft 9 is in the guide holes of the upper and lower mounts 14, 15, the main shaft 9 extends upwards through the guide holes of the casing 10, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com